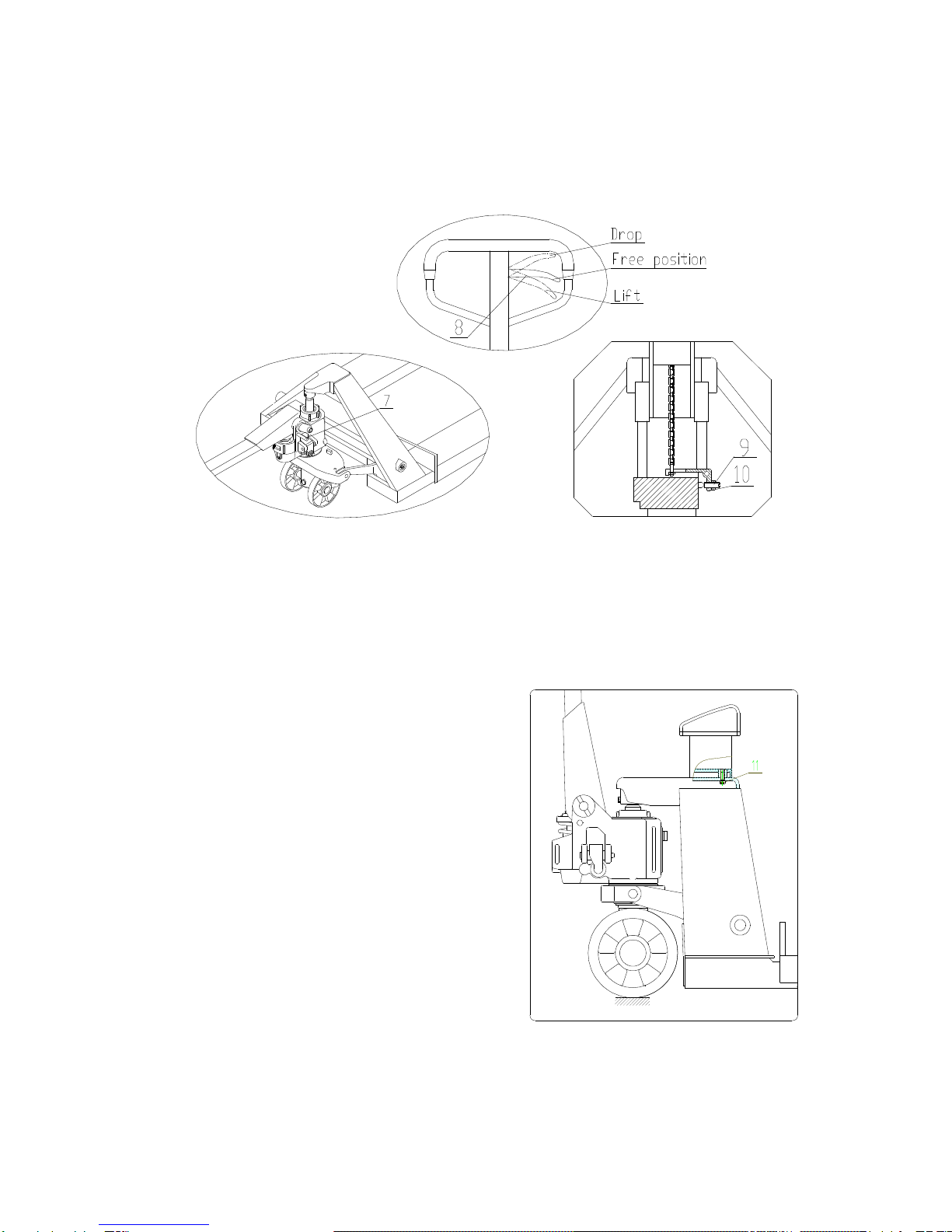

the handle kno 8 should e placed on dropping condition to let the truck forks down

to a certain position. Then insert the forks to the pallet and place the handle kno 8 on

the lifting condition so as to rock the hand grip to lift the truck forks.

5.3 During the process of moving cargo, the handle kno 8 should e placed on the free

position.

6. Oil

6.1 The oil capacity which oil pump needs is a out 250ml (or 0.25kg). According to the ISO

oil criterion, the choice of oil is 32# when the environment temperature during

-5~40℃.The choice of oil is low temperature oil when the environment temperature

during -35~-5℃.

6.2 Disposal of waste oil: Dispose the waste oil in terms of relative laws and for id pouring

out anywhere.

7. Maintenance

The routine check should e carried out daily and every a normal phenomenon should e

dealt with immediately. Please do not use faulty truck in order to prolong the service life. All

the rotary joints should renew the motor oil every three months. Especially pay more

attention to the place etween wheel and axis. Make sure that there is not any yarn or

other rags in order to keep all wheels running with handiness. Make sure the electric power

is full, instrument display and printing is in working condition. If the hand pallet truck with

scale has not een used for a long time, the attery should e removed and the quantity of

electricity should e enough all the time.

8. Working environment conditions

This type of hand pallet truck with scale is applica le to ordinary industrial environments

and usiness environments. The operating temperature is in the range of -5℃~+40℃. The

requirement of relative humidity is 10-95%RH. The working place must e plane. This type

of hand pallet truck with scale is not suita le to e used in the special place where there are

some explosive materials.

9. Warning level A

9.1 Please read the operation instruction carefully efore you operate the hand pallet truck

with scale and learn a out all the features of this type of hand pallet truck with scale.

9.2 If you want to let the cargo down y controlling the hand grip, you should lift the truck

forks a little at first, and then let the truck down slowly. It is for idden to pull the

handle kno with great force, ecause rapid dropping could cause some damages to

oth the hand pallet truck with scale and cargo.

9.3 Don’t rock the hand grip at a high speed and in a high frequency.