Safety Tips

oGeneral Tips

Observance of safety tips not only will eliminate possible dangers during installation and use,

but also it will result in longer lifetime and more continuous performance for the device. Non-

compliance with these tips, causes potential life-threatening or financial risks.

Note that the installation of this device requires expertise and specialization, and non-specialist

personnel are never allowed to install and set up the device, and corresponding personal injury

and material damage is the responsibility of the consumer.

oInput / Output Voltage

The electrical input and output voltage in the power system is high (380 V) and dangerous for

people. When installing these systems, be sure to disconnect the power of the device and run

all steps in the "Electrical Installation" section of the device guide.

oMechanical and Safety System

Motor speed control system is essentially part of a moving mechanical system that can be

dangerous for employees. Proper design of the mechanical system and other items are all

important in providing safety. Using the safety buttons to cut off the power of the machine in

emergency conditions or installing mechanical brake for the motor is required in some cases.

oFire

The speed control system is a part which is capable to fire and should therefore be placed inside

an appropriate panel with fire standards. Any damage caused by firing of the device is the

responsibility of the consumer, and only damages regarding the speed control system, which

originates from the device itself, will be covered by the warranty service, and even if the fire of

the device (even due to technical problems of the device itself) results in fire and damage to a

system other than the device, it will not be the responsibility of the company.

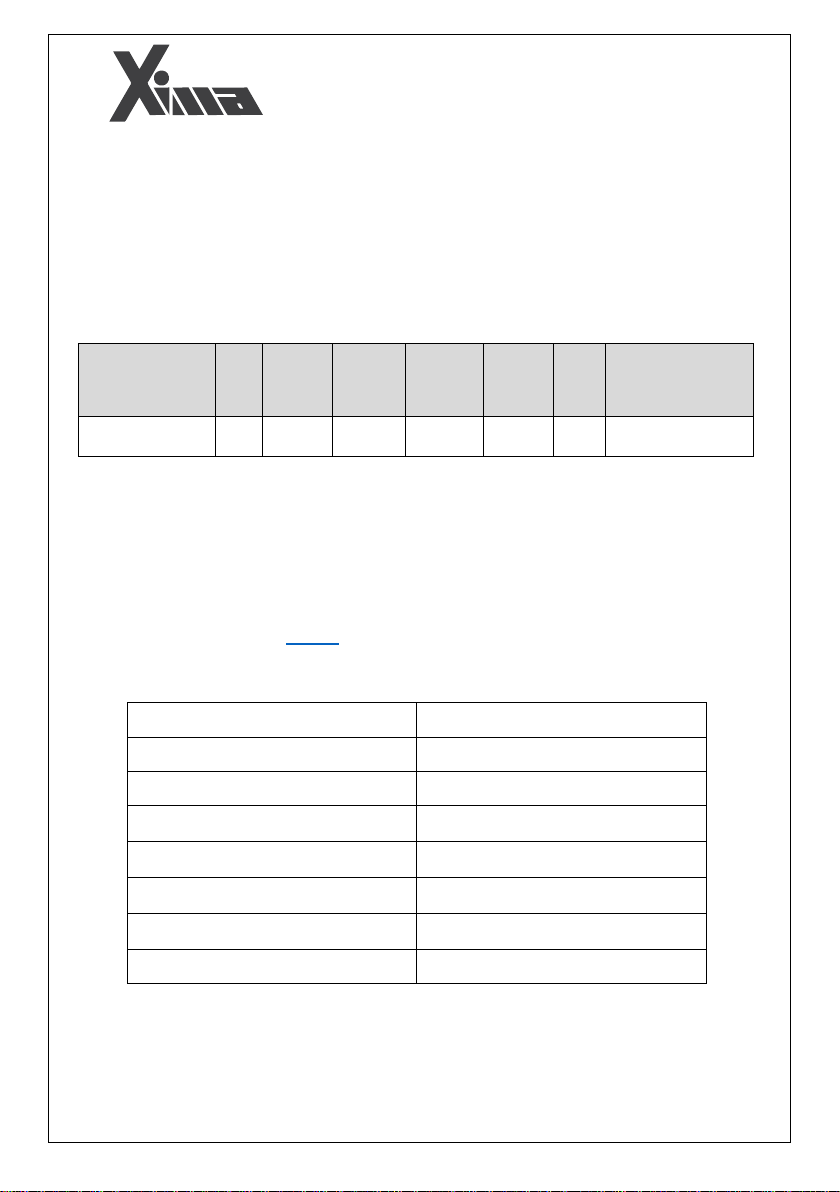

oFuses and Protective Circuits

The use of fuses and protective circuit in the input of the device is mandatory, and not applying

such parts will invalidate the warranty and increase the risk of personal injuries and material

damages. Refer to Table 1 for the right choice of the protective circuit.

oOverload range

In normal condition, the motor current must be less than the rated current of the inverter, and

if this current is more than 110% of the rated current, the device enters the overload phase, and

depending on the amount of overload, a fault will occur after a while and the system will require

to restart .

If the overload occurs when the motor is normally working with a current less than or equal to

the rated current, the duration of overweight fault will be shorter than the case in which the

overload occurs at the beginning of the motor startup. You can see this duration in the following

table.