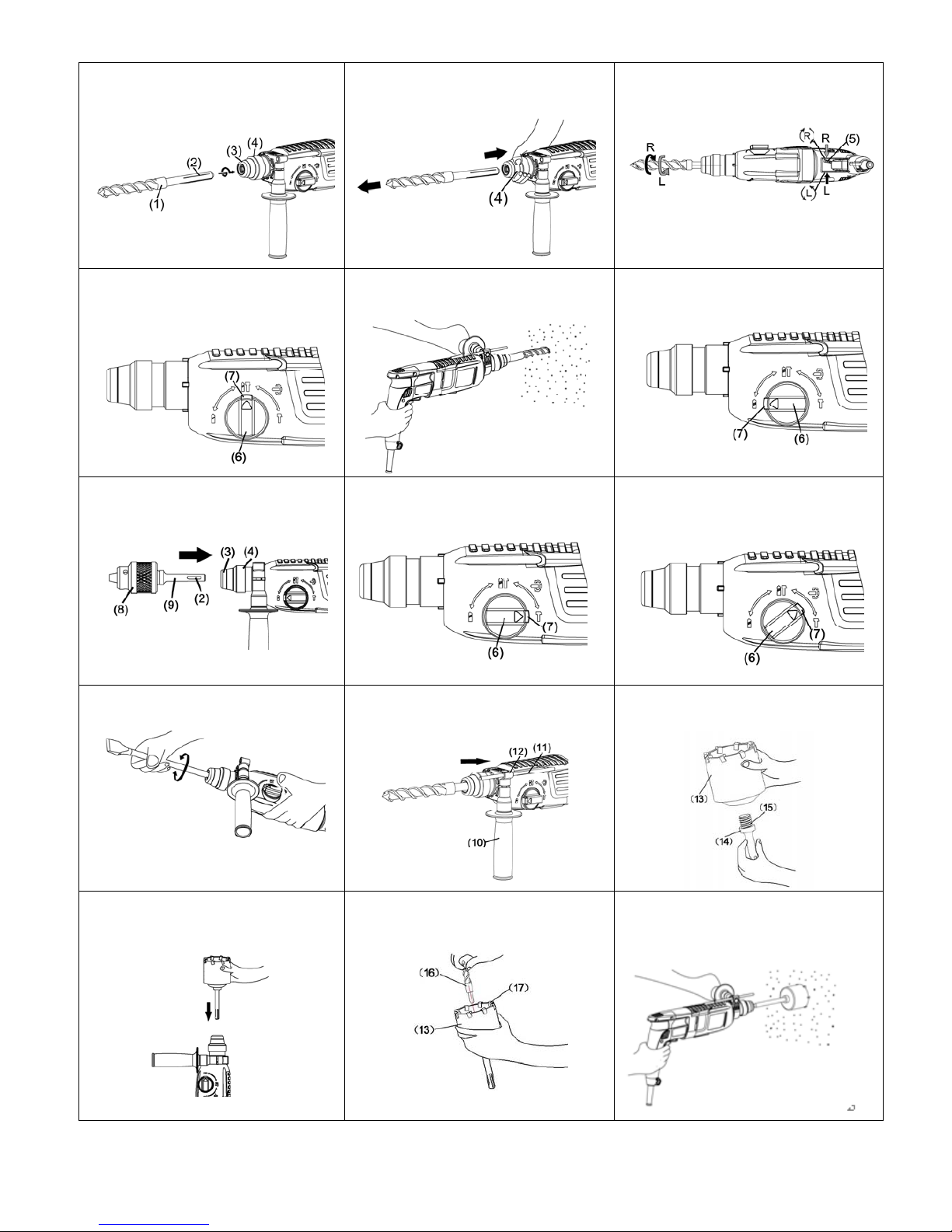

(1) Clean and lightly grease the shank portion of the drill bit.

(2) Insert the drill bit in a twisting manner into the tool holder until it latches itself (Fig.1)

(3) Pull the drill bit to make sure it is locked completely.

(4) To remover the drill bit, fully pull the flex sheath in the direction of the arrow and pull out the drill bit

(Fig.2).

5. Confirm the direction of bit rotation (Fig.3)

When the switch reversing bar turn to the “R” direction, the drill will clockwise rotation.

And when the switch reversing bar turn to the “L” direction, the drill will contrarotate.

HOW TO USE THE ROTARY HAMMER

CAUTION:

To prevent accidents, make sure to turn the switch off and disconnect the plug from the receptacle when

the drill bits and other various parts are installed or removed. The power switch should also be turned off

during a work break and after work.

1. Switch operation

The rotation speed of the drill bit can be controlled steplessly by varying the amount that the switch is

pilled. Speed is low when the switch is pulled slightly and increases as the switch is pulled more.

Continuous operation may be attained by pulling the switch and depressing the locked Pushbutton. To

turn the switch OFF, pull the switch again to disengage the locked Pushbutton, and release the switch to

its original position.

However, the switch can only be pulled in halfway during reverse and rotates at half the speed of

forward operation.

The switch locked Pushbutton is unusable during reverse.

2. When drilling at “rotation + hammering”:

(1) Switching to “rotation + hammering”

(a) Push the locked Pushbutton, release lock and turn the function knob.

(b) Align ▲of the function knob and of the Gear Case as illustrated in Fig.4.

(c) Release the locked Pushbutton to lock the function knob.

NOTE:

Turn the function knob (do not push the locked Pushbutton) to check if it is completely locked and

make sure that it does not turn.

(2) Mount the drill bit.

(3) Pull the switch after applying the drill bit tip to the drilling position (Fig.5).

(4) Pushing the rotary hammer forcibly is not necessary at all. Pushing slightly so that drill dust comes

out gradually is sufficient.

CAUTION:

Although this machine is equipped with a safety clutch, if the drill bit becomes bound in concrete or

other material, the resultant stoppage of the drill bit could cause the machine body to turn in reaction.

Ensure that the main handle and side handle are gripped firmly during operation.

3. Rotation only

(a) Push the locked Pushbutton, release lock and turn the function knob.

(b) Align ▲of the function knob and of the Gear Case as illustrated in Fig.6

c) Release the locked Pushbutton to lock the function knob.

NOTE:

Turn the function knob (do not push the locked Pushbutton) to check if it is completely locked and

make sure that it does not turn.