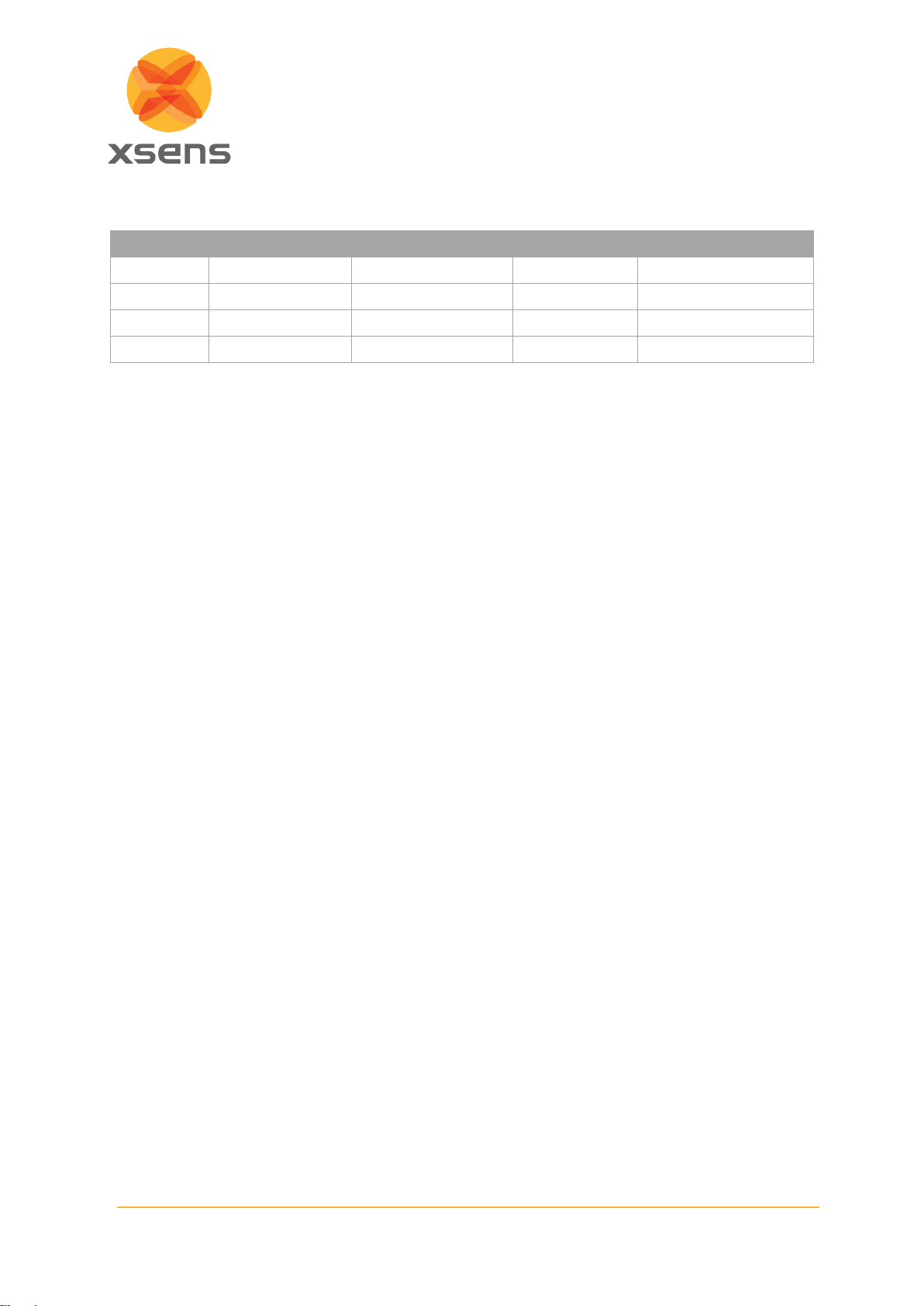

Table of Contents

1XSENS CUSTOMER SUPPORT AND BASE................................................................................ 6

2INTRODUCTION ............................................................................................................................ 7

2.1 FROM IMU TO GNSS/INS ............................................................................................................ 8

2.1.1 IMU .................................................................................................................................... 8

2.1.2 VRU ................................................................................................................................... 8

2.1.3 AHRS ................................................................................................................................. 8

2.1.4 GNSS/INS.......................................................................................................................... 8

2.2 XSENS MTI HARDWARE PLATFORMS .............................................................................................. 9

2.2.1 MTi 1-series ....................................................................................................................... 9

2.2.2 MTi 600-series ................................................................................................................... 9

2.2.3 MTi 10-series ..................................................................................................................... 9

2.2.4 MTi 100-series ................................................................................................................... 9

3GETTING STARTED WITH THE MTI .......................................................................................... 11

3.1 OVERVIEW MTI DEVELOPMENT KIT.............................................................................................. 11

3.1.2 MT Software Development Kit (MT SDK)........................................................................ 13

3.1.3 Low-level Communication................................................................................................ 13

3.1.4Terms of use of MT Software Suite ................................................................................. 13

4MTI SYSTEM OVERVIEW ........................................................................................................... 15

4.1 TEST AND CALIBRATION .............................................................................................................. 15

4.2 COORDINATE SYSTEMS ............................................................................................................... 15

4.2.1 Calibrated inertial data and magnetic field data .............................................................. 15

4.2.2 Orientation increment and Velocity increment (dq and dv) ............................................. 16

4.2.3 Orientation data ............................................................................................................... 17

4.2.4 Velocity data .................................................................................................................... 18

4.2.5 Position data .................................................................................................................... 19

4.3 PHYSICAL SENSOR MODEL........................................................................................................... 19

4.3.1 Calibrated ∆q and ∆v outputs .......................................................................................... 20

4.3.2 Calibrated inertial and magnetic data outputs ................................................................. 20

4.3.3 High-rate (HR) inertial data outputs ................................................................................. 20

4.3.4 Free acceleration ............................................................................................................. 21

4.4 XSENS SENSOR FUSION ALGORITHMS ......................................................................................... 22

4.4.1 Internal Sensor Bias Estimation....................................................................................... 22

4.4.2 Roll and Pitch estimation ................................................................................................. 22

4.4.3 Heading/yaw estimation................................................................................................... 23

4.4.4 Velocity and Position estimation ...................................................................................... 23

4.4.5 Initialization ...................................................................................................................... 24

4.4.6 Filter Profile options ......................................................................................................... 24

4.4.7 Additional setting options and features............................................................................ 24

4.5 MTI SERIES INTERFACE OPTIONS ................................................................................................. 26

4.6 TIMING AND SYNCHRONIZATION ................................................................................................... 26

5INPUT AND OUTPUT SPECIFICATION...................................................................................... 27

5.1 OVERVIEW OF DATA OUTPUT PROTOCOLS .................................................................................... 27

5.2 OVERVIEW OF DATA INPUTS......................................................................................................... 27

5.3 BUILT-IN SELF-TEST .................................................................................................................... 27

5.4 TIMESTAMP AND PACKET COUNTER OUTPUT ................................................................................. 27

5.5 STATUS WORD ............................................................................................................................ 28