cylindrical tank is the brine tank. It is the tank where regular softener salt top up is required from time to time. So please

make sure it’s accessible at all times.

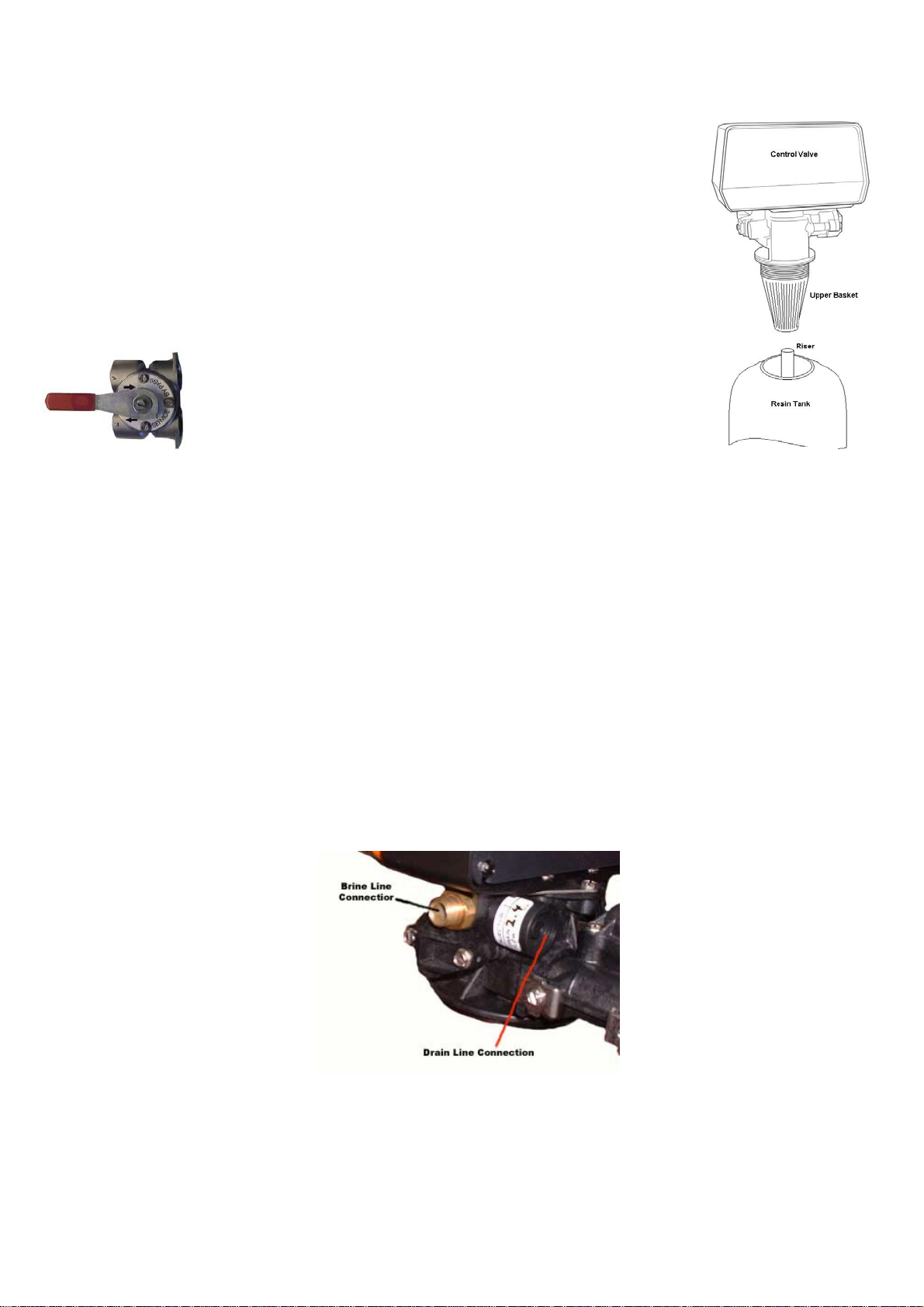

Step 2

Locate the cold/hot water (maximum water temperature is 65°C) supply and a nearby floor

drain. Ensure that the top distributor screen is attached to the bottom of the control

valve. Lubricate the o-ring on the bottom of the control valve that will seal with the tank

opening. Insert the riser pipe into the top distributor screen and then thread on the control

valve being careful not to cross thread it into the top tank threads. Hand tighten the control

valve on the tank until fitted snugly.

Step 3

Attach the Bypass valve (BSP Threads 3/4") to the control valve.

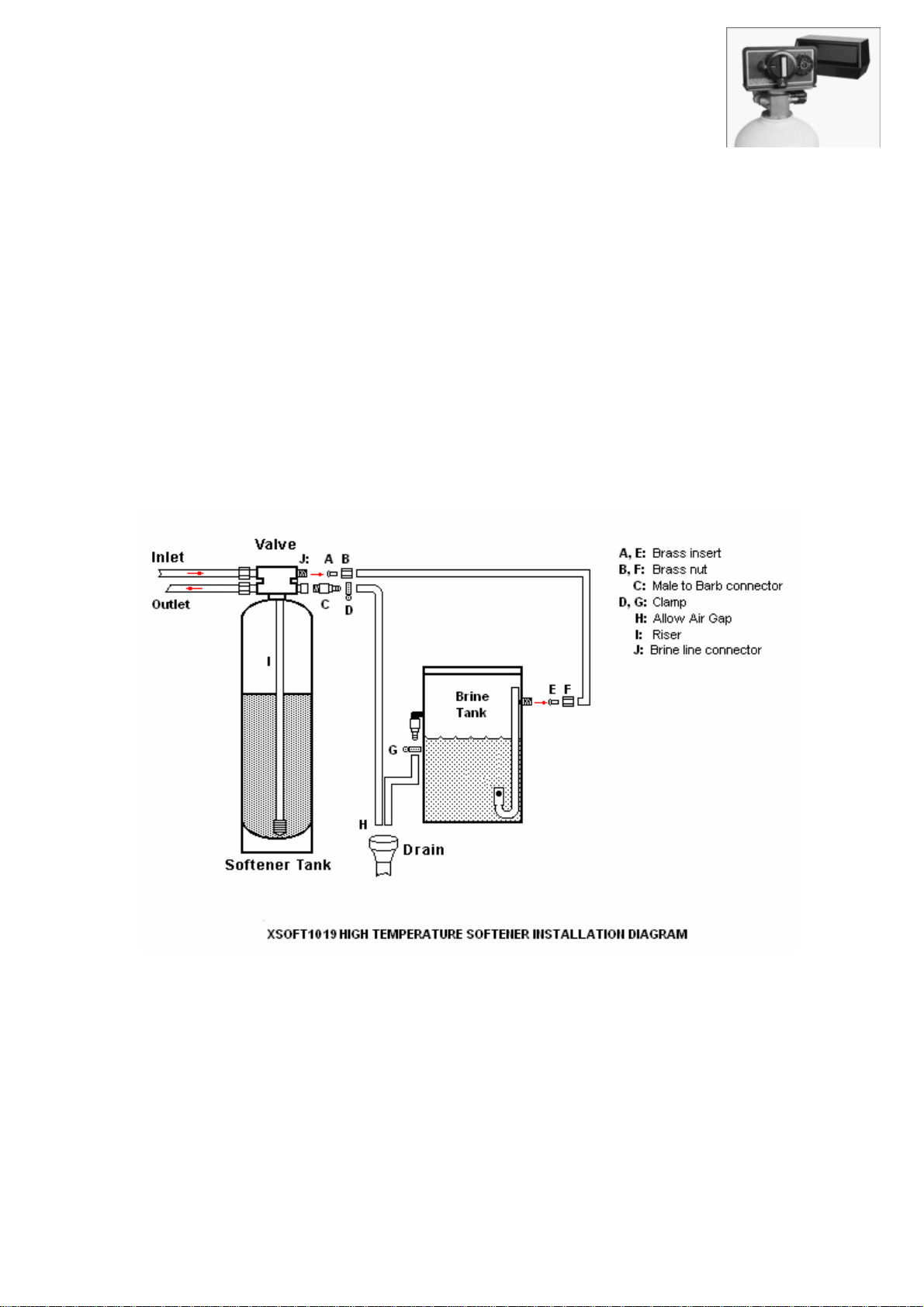

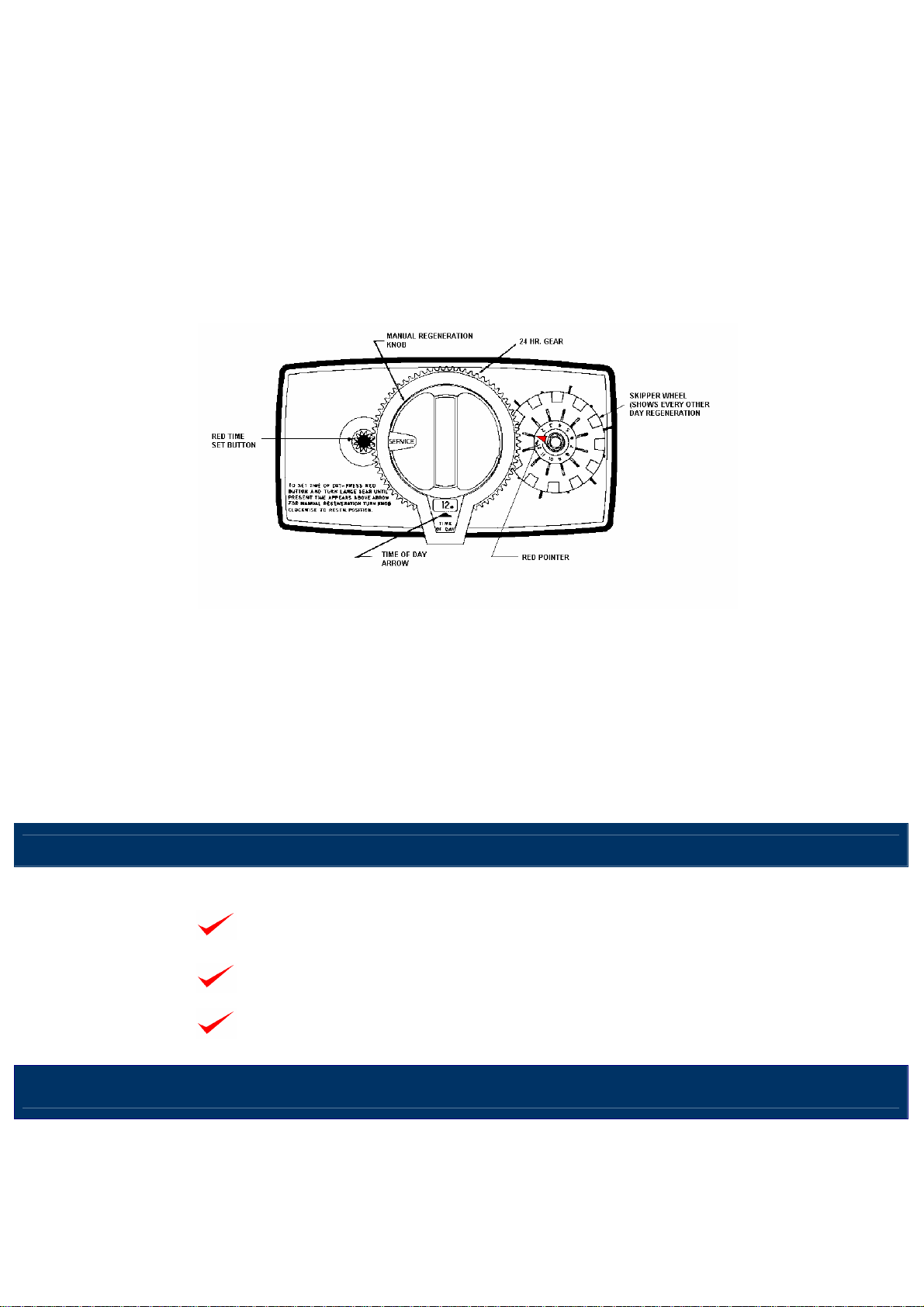

Step 4

Connect the inlet and outlet water lines. (Please note that the maximum working pressure for the system is 125psi. A

pressure reduction valve is strongly recommended). Run a drain line to a floor drain from the ½” connection on the control

valve. This should be no longer than 20 feet from the water softener. The drain line should be a flexible ½” i.d. plastic

which can be of vinyl or polyethylene type material and should be secured with a small clamp over the drain fitting. The

backwashing drain line will be under high pressure when the backwash cycle is working. Make sure the drain line is

secured. The drain line will need to drain into a floor drain.

CAUTION:PLEASE OBSERVE THE DIRECTION OF THE INLET AND OUTLET ARROW OF THE VALVE TO ENSURE THE SOFTENER IS PIPED

PROPERLY.

Step 5

First attach the brass nut to the tubing then put the brass insert inside the tubing (on both ends of the tube) and screw the

tubing and nut to the brass thread of the connector. Connect the clear brine line to the brine line connector of the control

valve. Attach the other end of the tube to the brine tank ensuring that both connections are tight.

NOTE:NEVER CONNECT THE DRAIN LINE DIRECTLY INTO THE FLOOR DRAIN.ALLOW AN AIR GAP BETWEEN THE DRAIN LINE AND

WASTE LINE TO PREVENT POSSIBILITY OF BACK SIPHONING.

Step 6

Fill the resin tank with water by opening the bypass valve. Place the valve in the rapid rinse position to rinse the resin for 1

minute then back into a service position.

Step 7

Put one bag of 25kg softener salt and add about 8 litre of water into the brine tank (just above the water level) (use softener

salt because they are manufactured for water softener systems).

Diagram 2