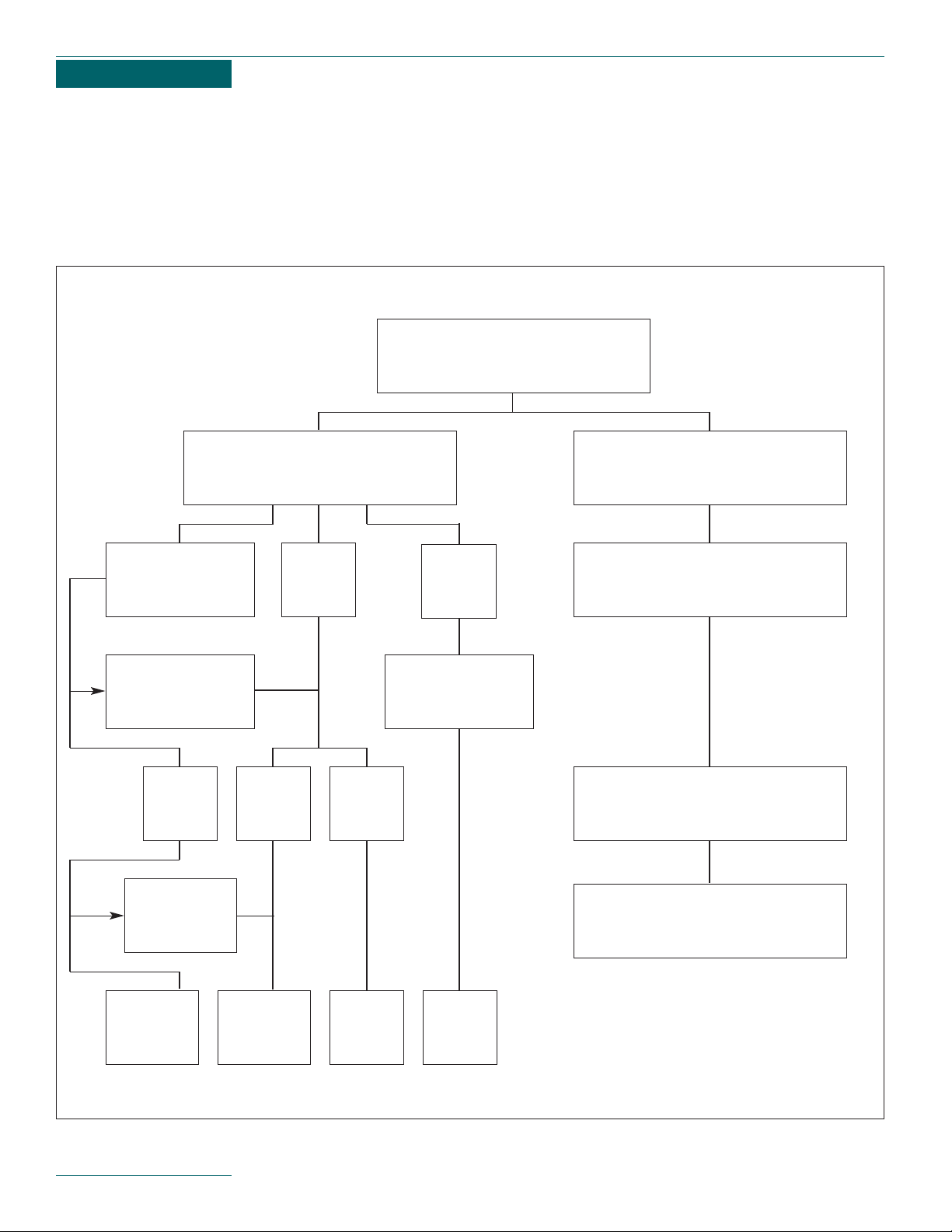

Steam Trap

Functional

Requirements

Selecting the

proper type of

steam trap is an

important element

in steam systems.

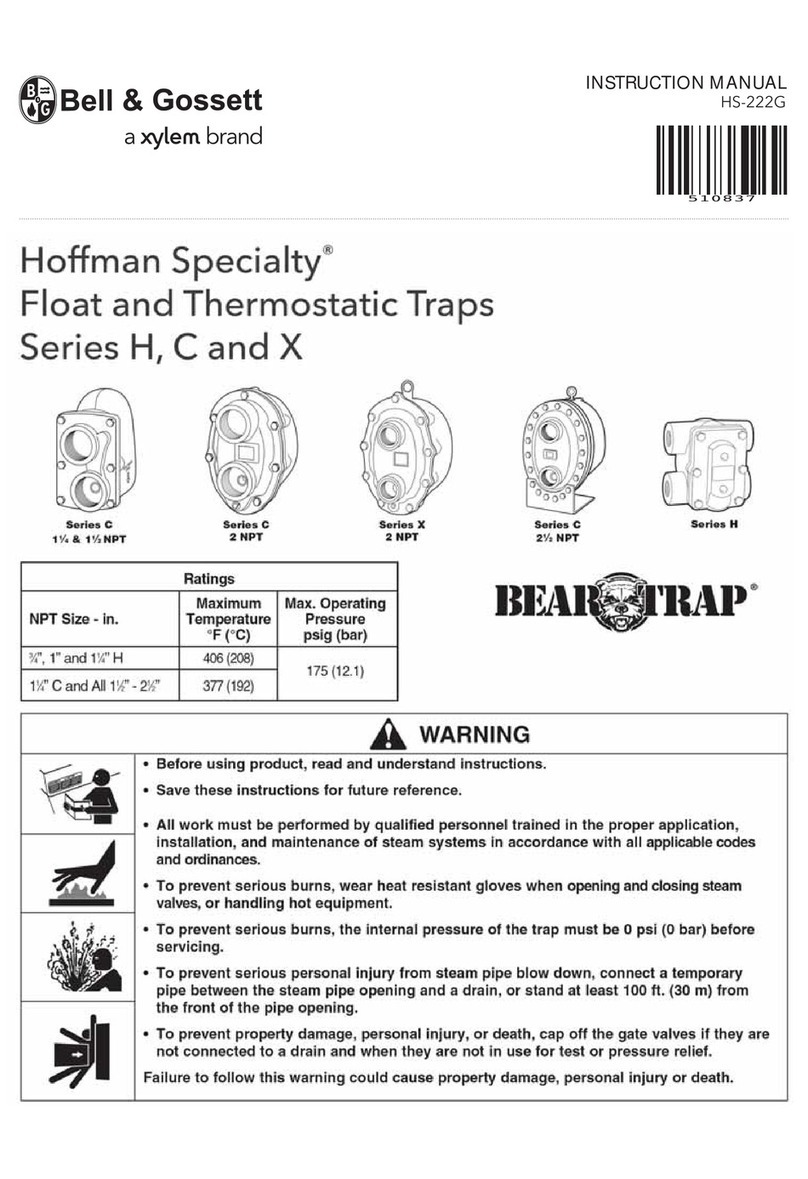

There are many types of steam traps each

having its unique characteristics and system

benefits. Hoffman Specialty offers thermostat-

ic, thermodisc, float and thermostatic, and

bucket traps which are the most commonly

used types. Deciding which type of trap to use

is sometimes confusing and, in many cases,

more than one type can be used. The follow-

ing is intended to point out system conditions

that may be encountered and the characteris-

tics of each type of trap.

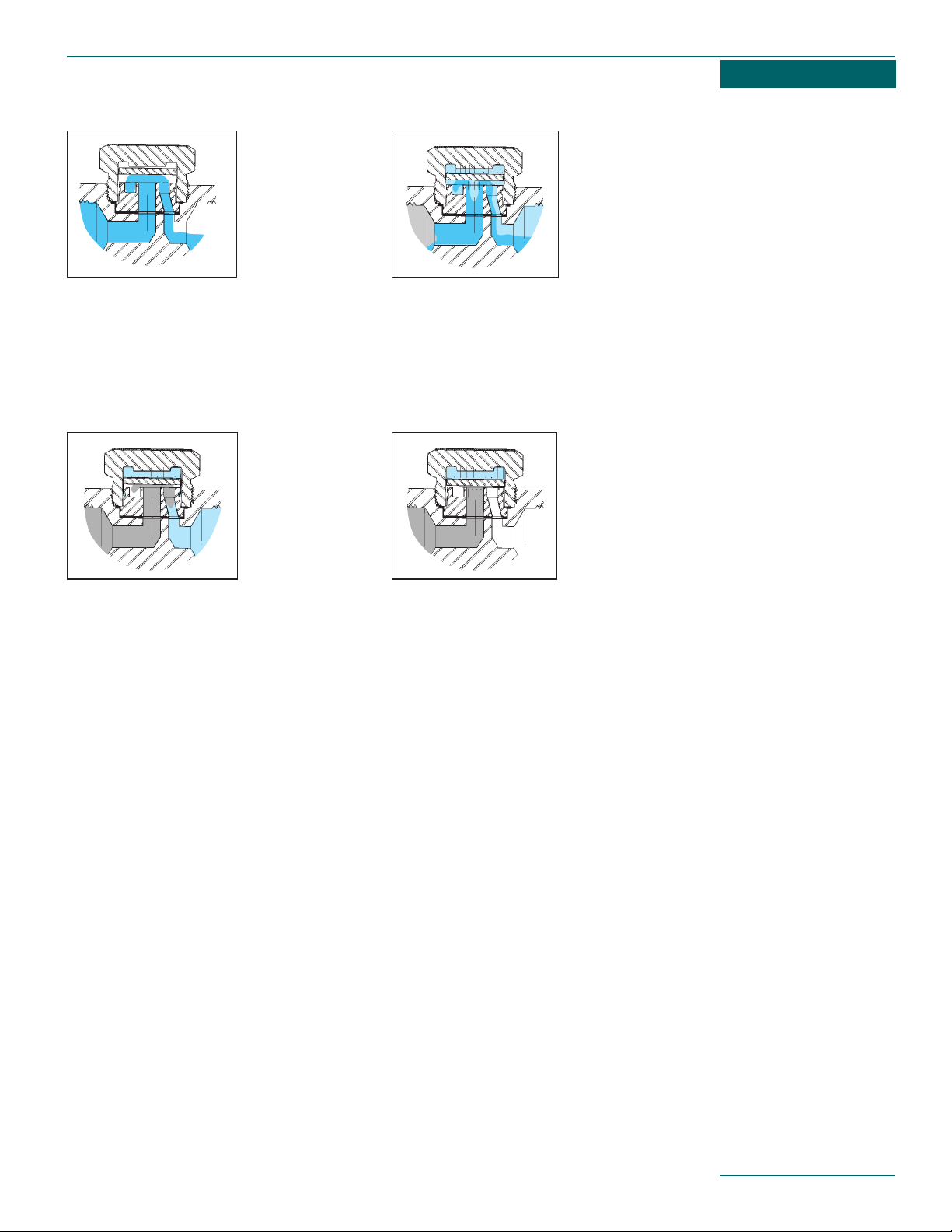

Within steam systems, important considera-

tions must be taken into account. These con-

siderations include venting of air during

start-up; variations of system pressures and

condensing loads; operating pressure and

system load; continuous or intermittent opera-

tion of system; usage of dry or wet return

lines; and overall probability of water hammer.

Air Venting

At start-up all steam piping, coils, drums, tracer

lines, or steam spaces contain air. This air

must be vented before steam can enter.

Usually the steam trap must be capable of

venting the air during this start-up period. A

steam heating system will cycle many times

during a day. Fast venting of air is necessary

to obtain fast distribution of steam for good

heat balance. A steam line used in process

may only be shut down once a year for repair

and venting of air may not be a major con-

cern.

Modulating Loads

When a modulating steam regulator is used,

such as on a heat exchanger, to maintain a

constant temperature over a wide range of

flow rates and varying inlet temperatures, the

condensate load and differential pressure

across the trap will change. When the conden-

sate load varies, the steam trap must be

capable of handling a wide range of condi-

tions at constantly changing differential pres-

sures across the trap.

Differential Pressure Across Trap

When a trap drains into a dry gravity return

line, the pressure at the trap discharge is nor-

mally at O psig. When a trap drains into a wet

return line or if the trap must lift condensate

to an overhead return line, there will normally

be a positive pressure at the trap discharge.

To assure condensate drainage, there must

be a positive differential pressure across the

trap under all load conditions.

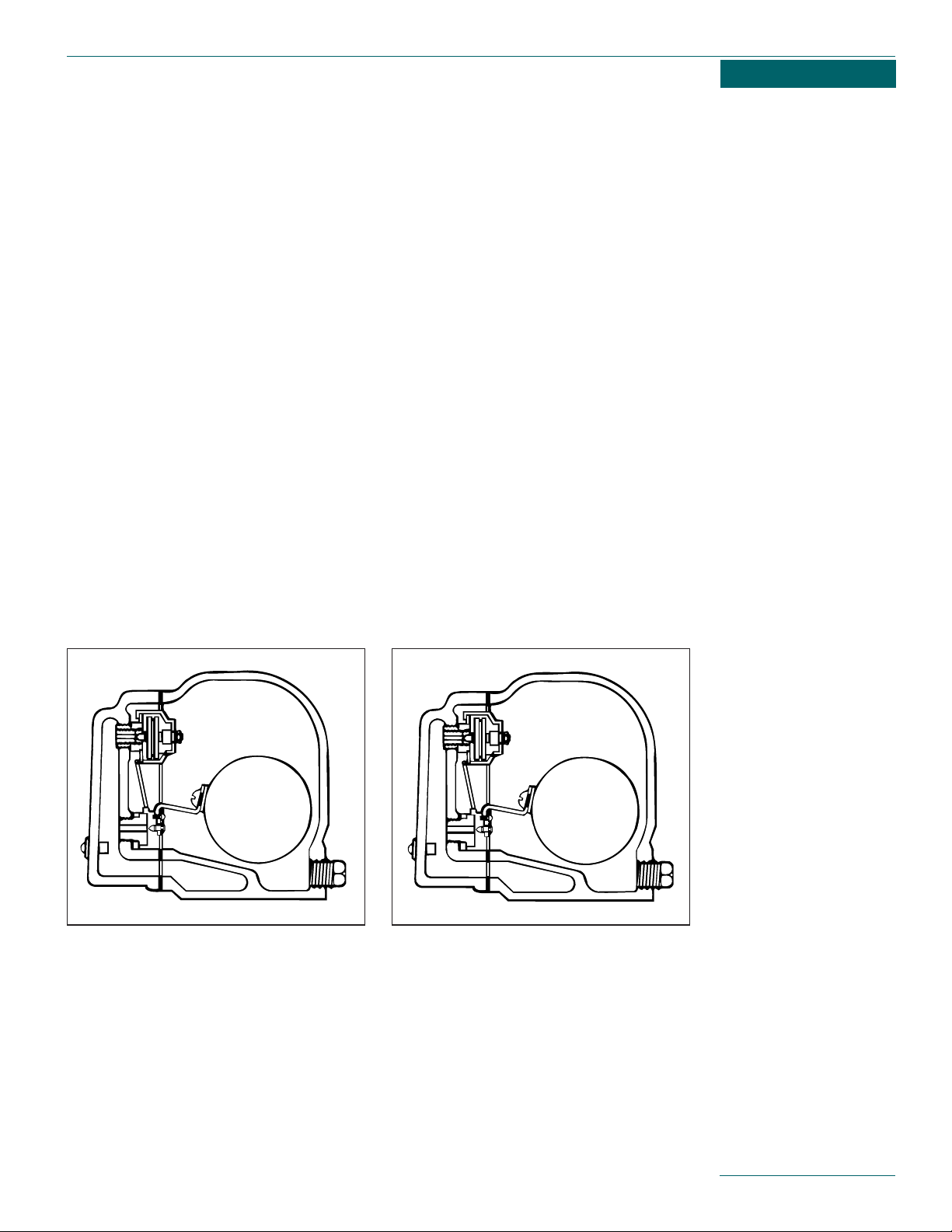

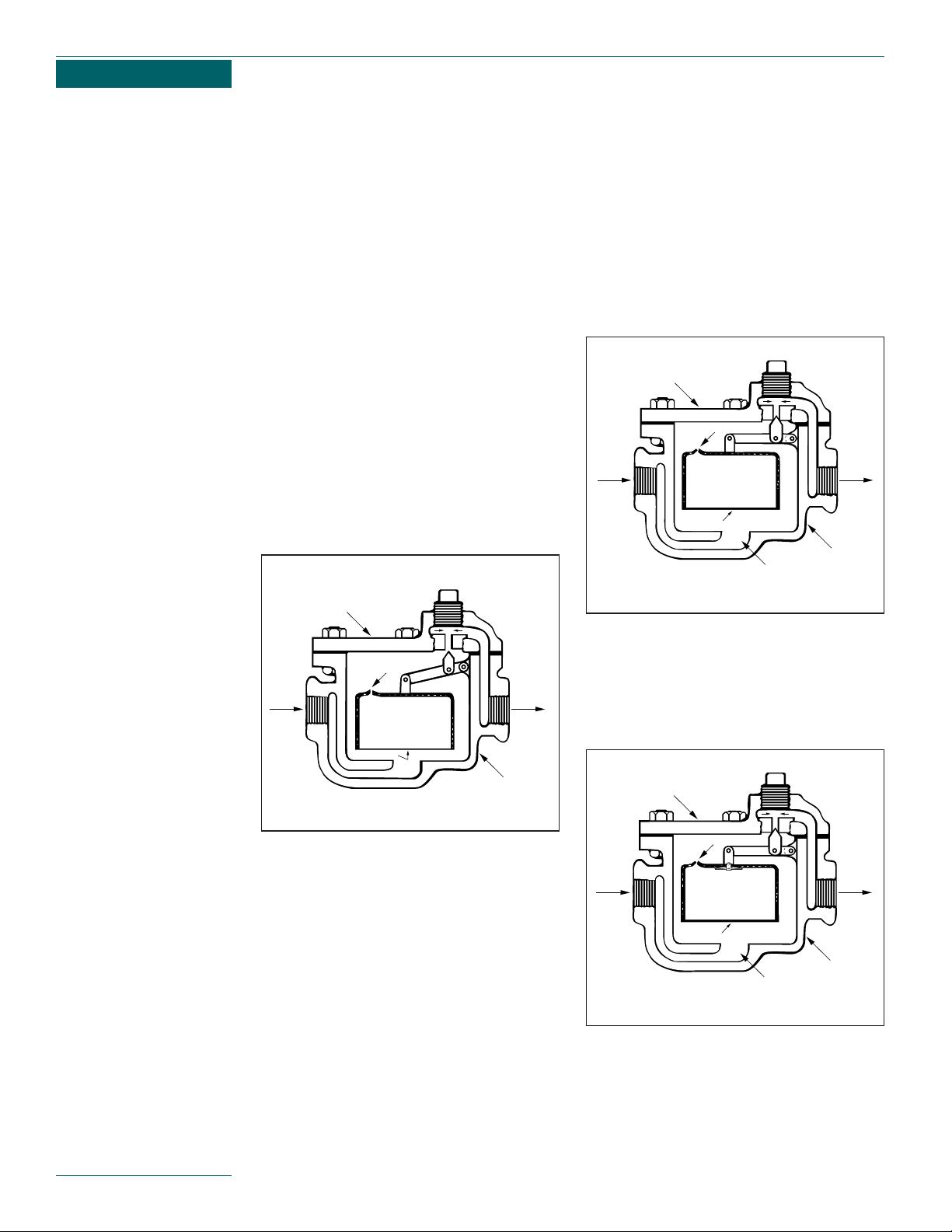

Water Hammer

When a trap drains high temperature conden-

sate into a wet return, flashing may occur.

When the high temperature condensate at

saturation temperature discharges into a

lower pressure area, this flashing causes

steam pockets to occur in the piping, and

when the latent heat in the steam pocket is

released, the pocket implodes causing water

hammer. Floats and bellows can be damaged

by water hammer conditions.

When traps drain into wet return lines, a

check valve should be installed after the trap

to prevent backflow. The check valve also

reduces shock forces transmitted to the trap

due to water hammer. Where possible, wet

returns should be avoided.

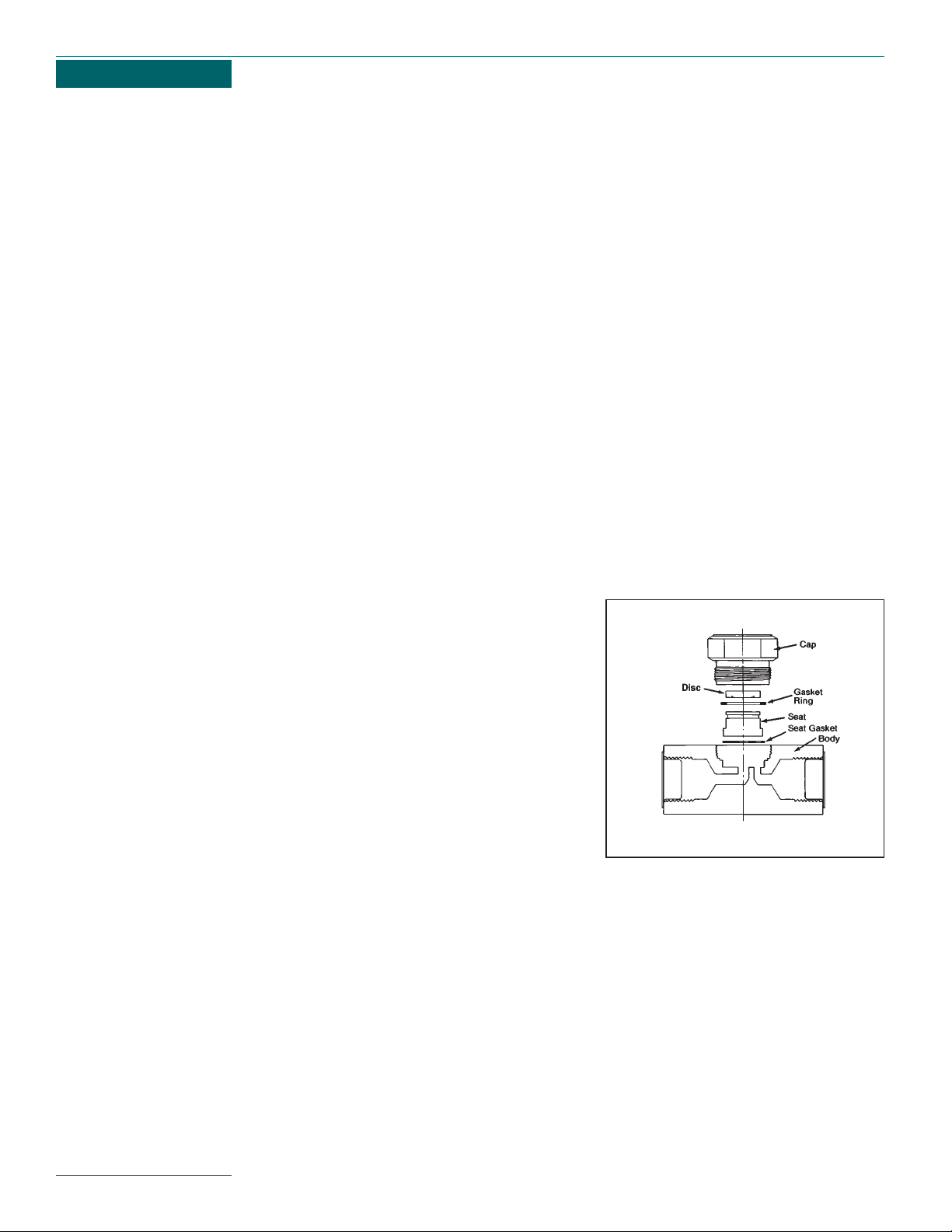

Application

The design of the equipment being drained is

an important element in the selection of the

trap. Some equipment will permit the conden-

sate to back up. When this occurs the steam

and condensate will mix and create water

hammer ahead of the trap. A shell and tube

heat exchanger has tube supports in the

shell. If condensate backs up in the heat

exchanger shell, steam flowing around the

tube supports mixes into the condensate and

causes steam pockets to occur in the conden-

sate. When these steam pockets give up their

latent heat, they implode and water hammer

occurs, the water hammer often damages the

heat exchanger tube bundle. The trap selec-

tion for these types of conditions must com-

pletely drain condensate at saturation

temperature under all load conditions.

Steam mains should be trapped to remove all

condensate at saturation temperature. When

condensate backs up in a steam main, steam

flow through the condensate can cause water

hammer. This is most likely to occur at expan-

sion loops and near elbows in the steam

main.

Applications such as tracer lines or vertical

unit heaters do not mix steam and conden-

sate. In a tracer line, as the steam condens-

es, it flows to the end of the tracer line. Back

up of condensate ahead of the trap does not

cause water hammer. Steam does not pass

through condensate.

Vertical unit heaters normally have a steam

manifold across the top. As the steam con-

denses in the vertical tubes, it drains into a

bottom condensate manifold. Because steam

does not pass through the condensate, water

hammer should not occur.

4

Introduction