P.O.Box 1, Hamamatsu, Japan

101294

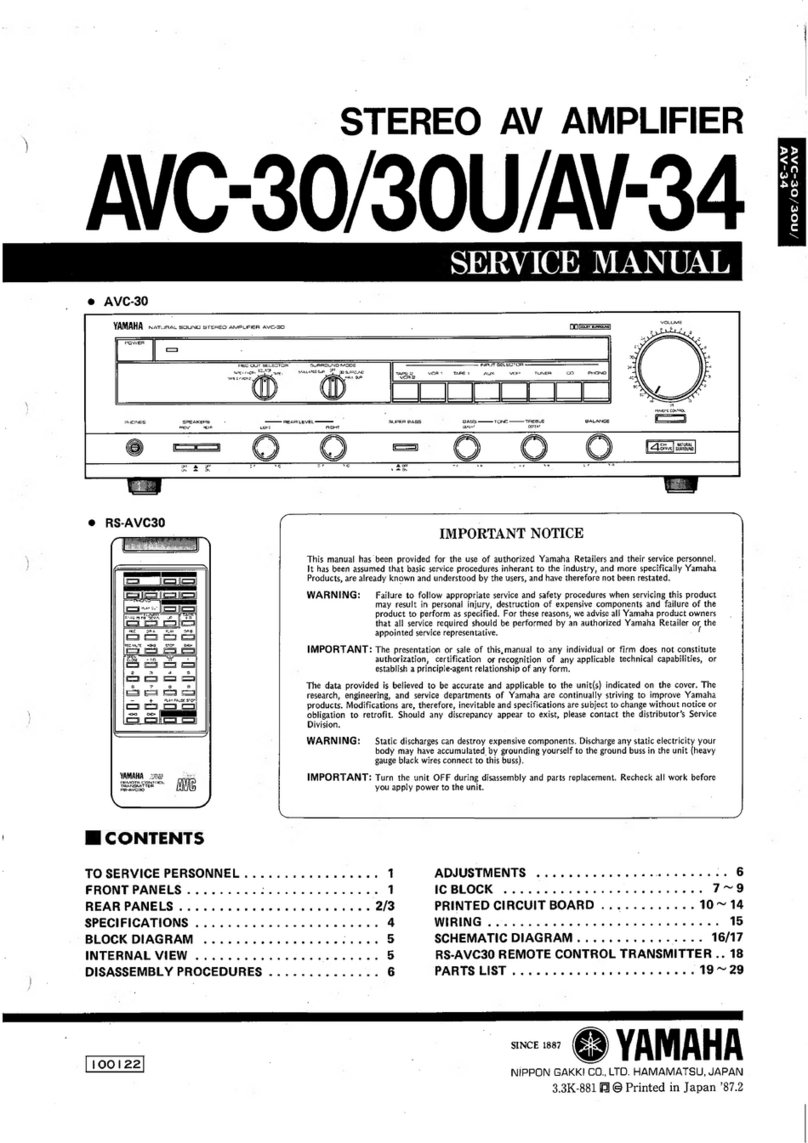

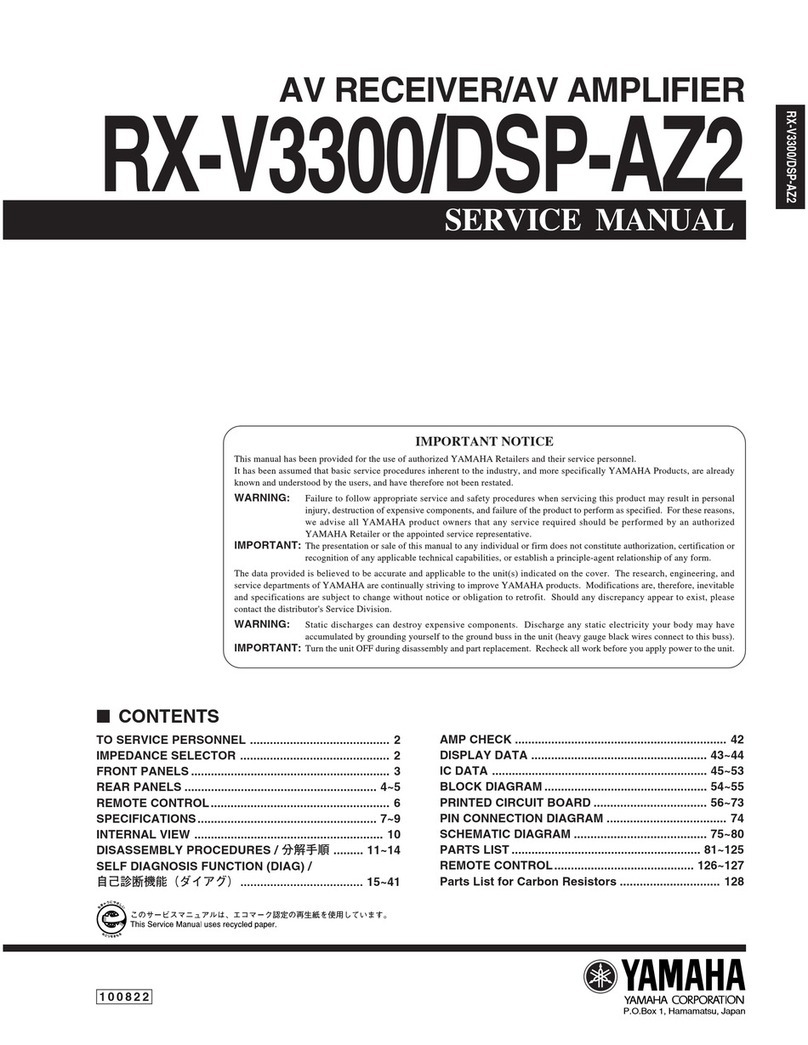

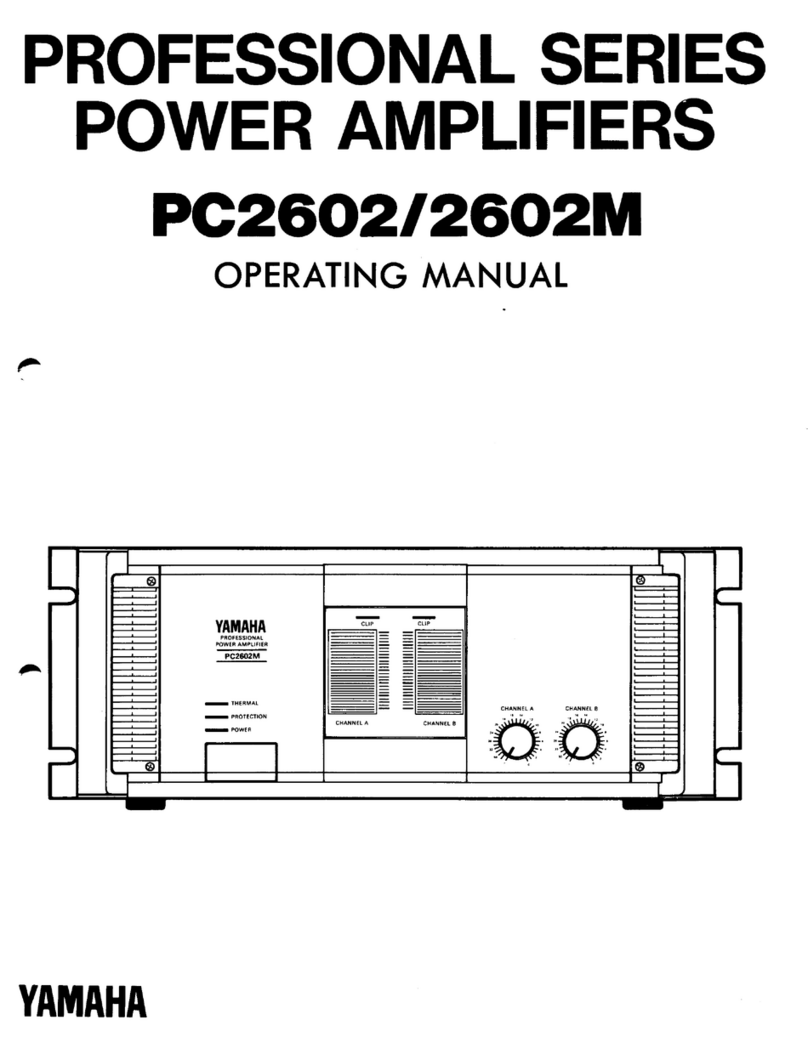

SERVICE MANUAL

INTEGRATED AMPLIFIER

'13.12

A-S201

Copyright (c) Yamaha Corporation All rights reserved.

This manual is copyrighted by Yamaha and may not be copied or

redistributed either in print or electronically without permission.

IMPORTANT NOTICE

This manual has been provided for the use of authorized Yamaha Retailers and their service personnel.

It has been assumed that basic service procedures inherent to the industry, and more specifically Yamaha Products, are already known

and understood by the users, and have therefore not been restated.

WARNING: Failure to follow appropriate service and safety procedures when servicing this product may result in personal injury,

destruction of expensive components, and failure of the product to perform as specified. For these reasons, we advise

all Yamaha product owners that any service required should be performed by an authorized Yamaha Retailer or the

appointed service representative.

IMPORTANT: The presentation or sale of this manual to any individual or firm does not constitute authorization, certification or

recognition of any applicable technical capabilities, or establish a principle-agent relationship of any form.

The data provided is believed to be accurate and applicable to the unit(s) indicated on the cover. The research, engineering, and service

departments of Yamaha are continually striving to improve Yamaha products. Modifications are, therefore, inevitable and specifications

are subject to change without notice or obligation to retrofit. Should any discrepancy appear to exist, please contact the distributor's

Service Division.

WARNING: Static discharges can destroy expensive components. Discharge any static electricity your body may have

accumulated by grounding yourself to the ground buss in the unit (heavy gauge black wires connect to this buss).

IMPORTANT: Turn the unit OFF during disassembly and part replacement. Recheck all work before you apply power to the unit.

■CONTENTS

TO SERVICE PERSONNEL ............................................ 2

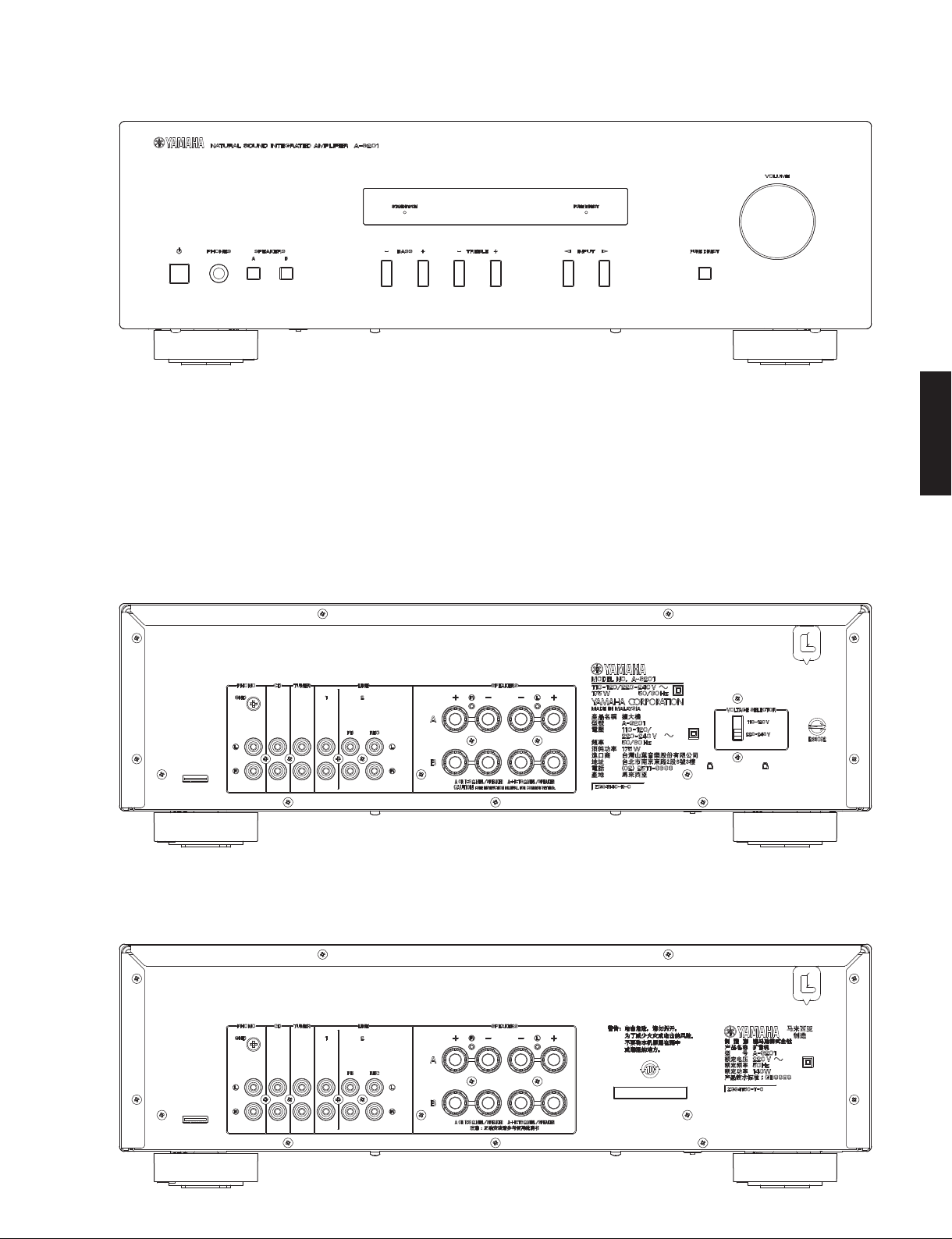

FRONT PANEL ...............................................................3

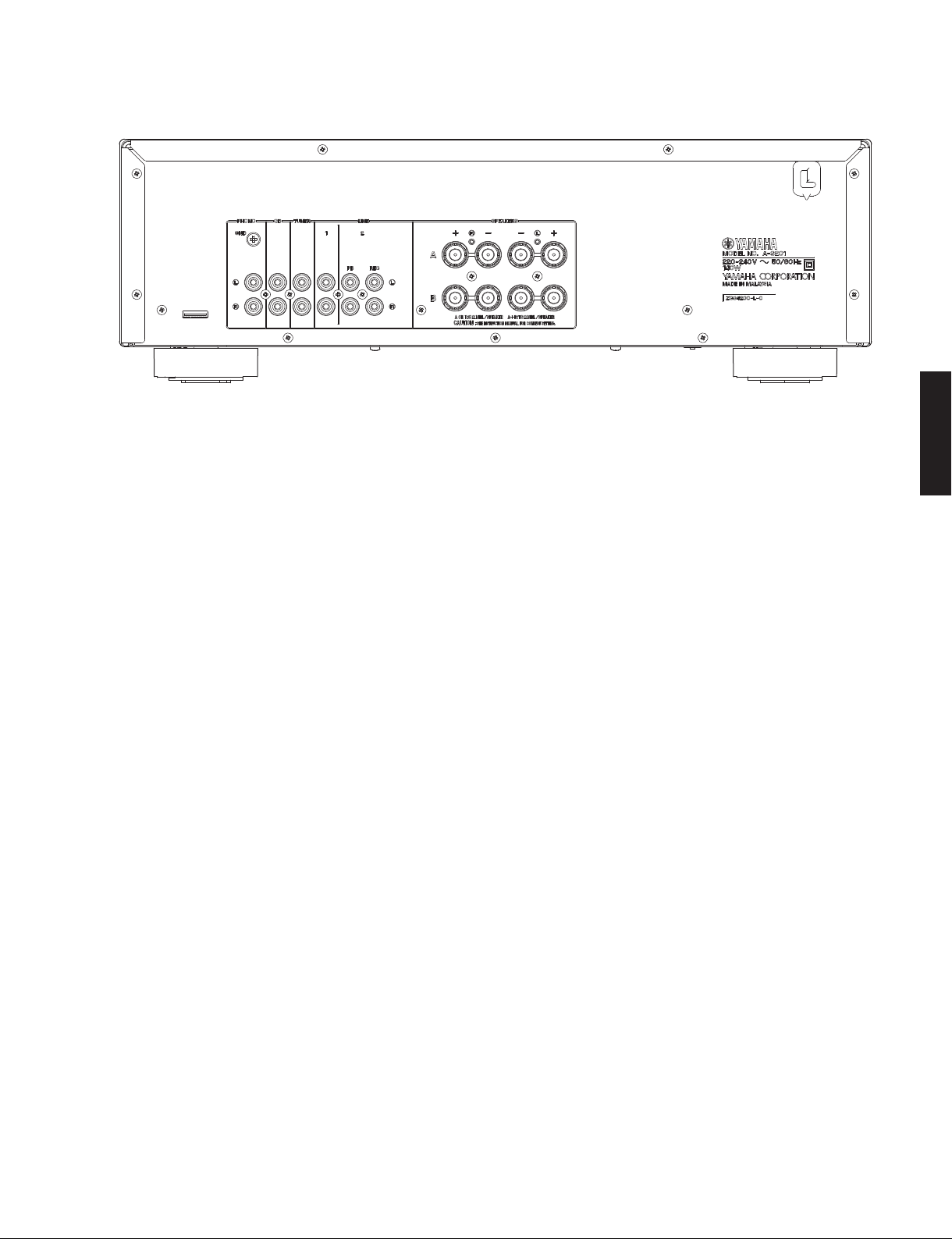

REAR PANELS ...........................................................3–5

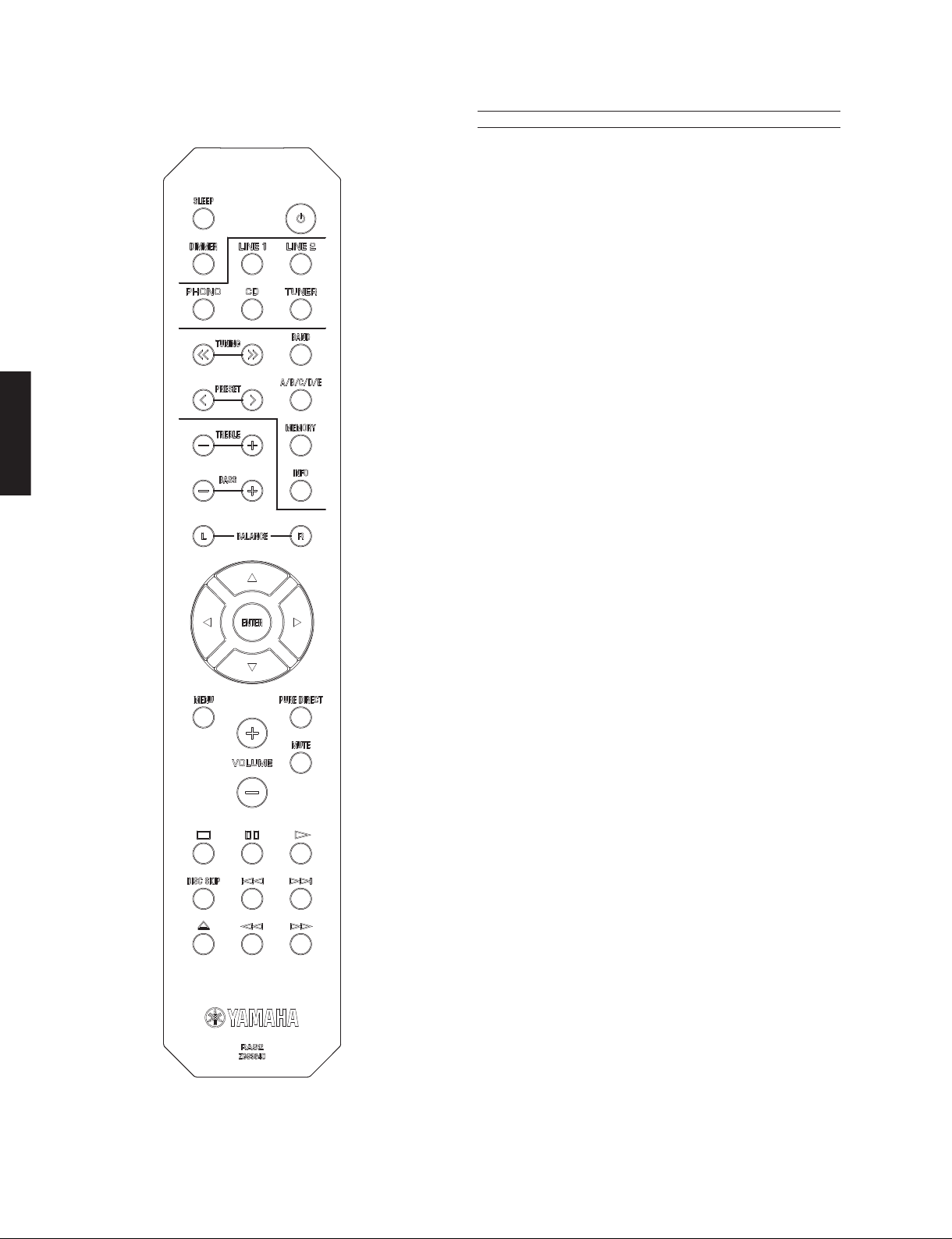

REMOTE CONTROL PANEL ..........................................6

SPECIFICATIONS .......................................................6–7

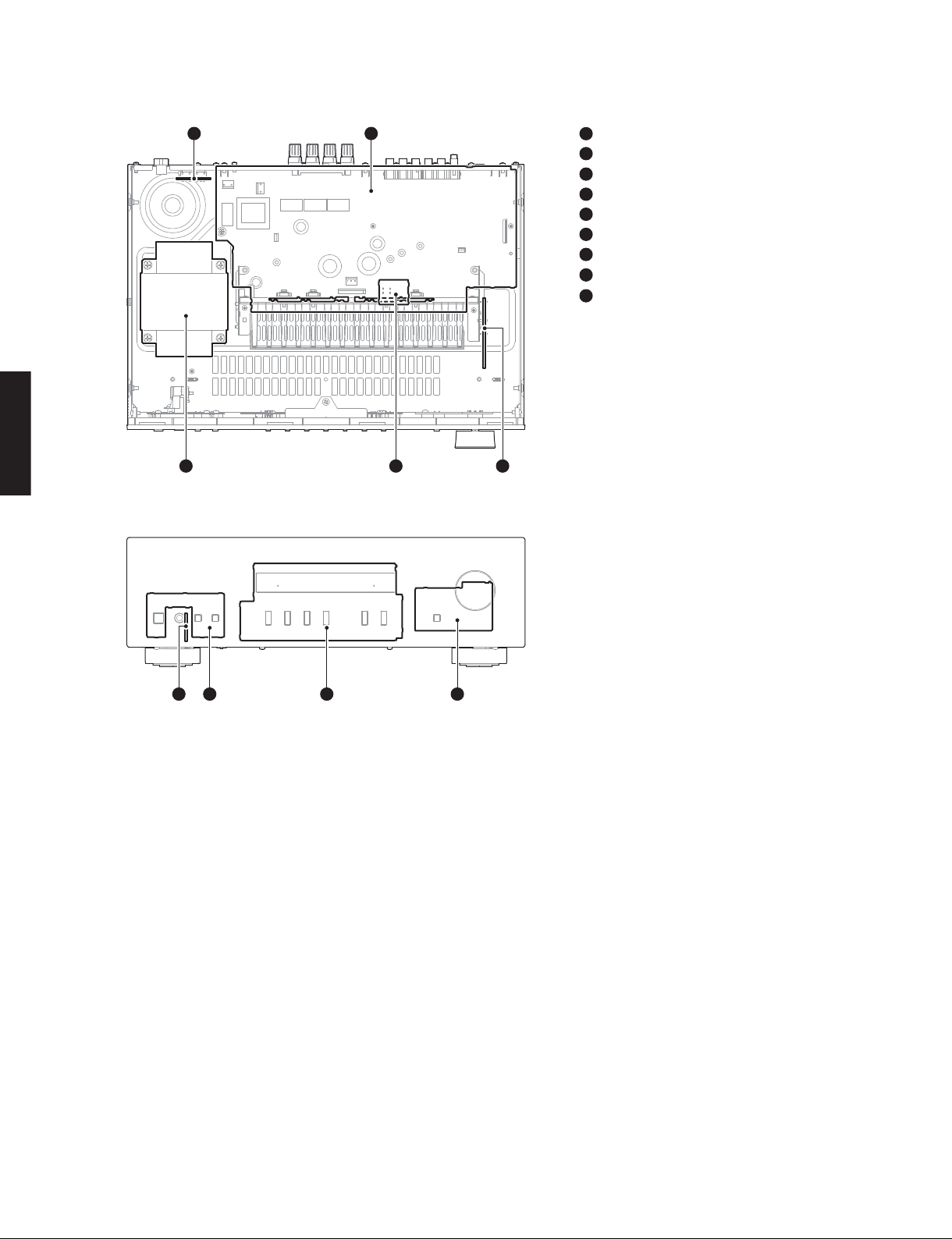

INTERNAL VIEW ............................................................8

SERVICE PRECAUTIONS ..............................................8

DISASSEMBLY PROCEDURES ............................... 9–11

UPDATING FIRMWARE .......................................... 12–17

SELF-DIAGNOSTIC FUNCTION ............................ 18–27

DISPLAY DATA .............................................................28

IC DATA ...................................................................29–31

BLOCK DIAGRAM ........................................................32

WIRING DIAGRAM ....................................................... 33

PRINTED CIRCUIT BOARDS .................................34–39

PIN CONNECTION DIAGRAMS ...................................40

SCHEMATIC DIAGRAM ................................................41

REPLACEMENT PARTS LIST ................................43–49

REMOTE CONTROL .....................................................50

ADVANCED SETUP ......................................................51

A-S201