CDC-697

CDC-697

2

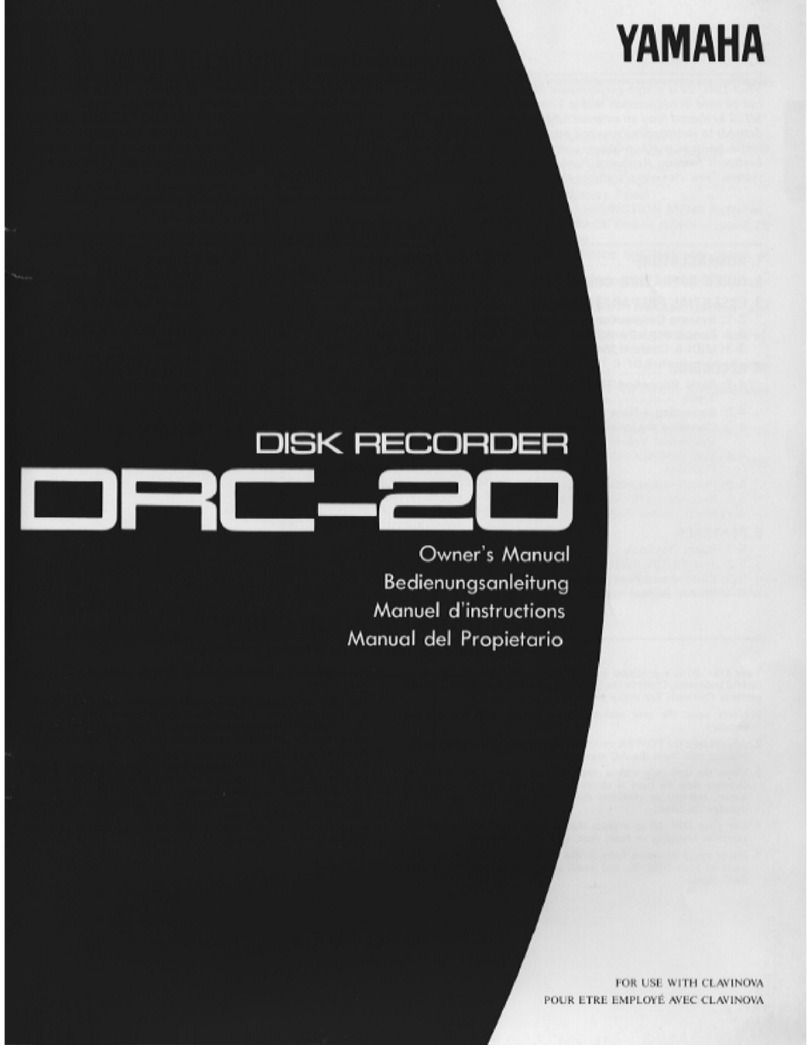

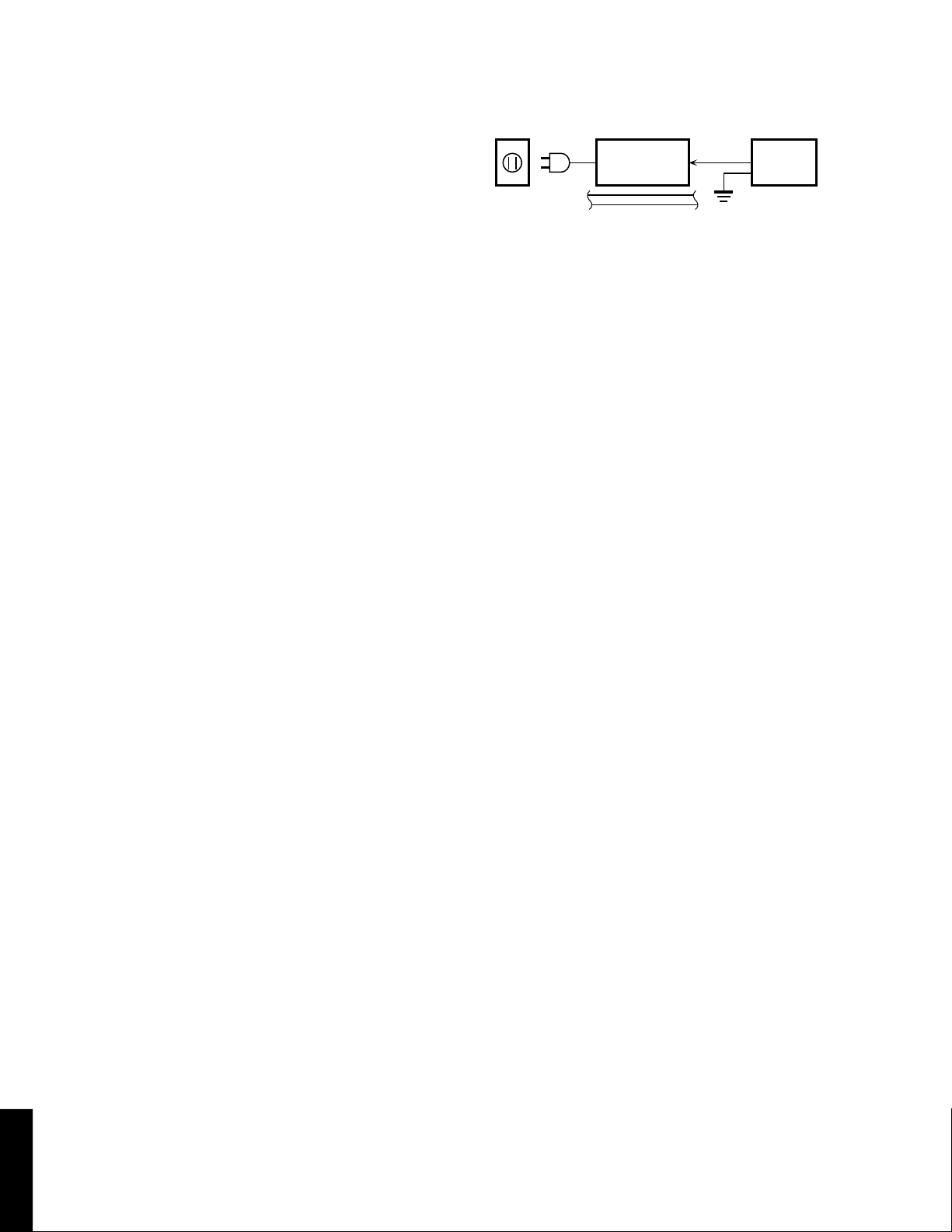

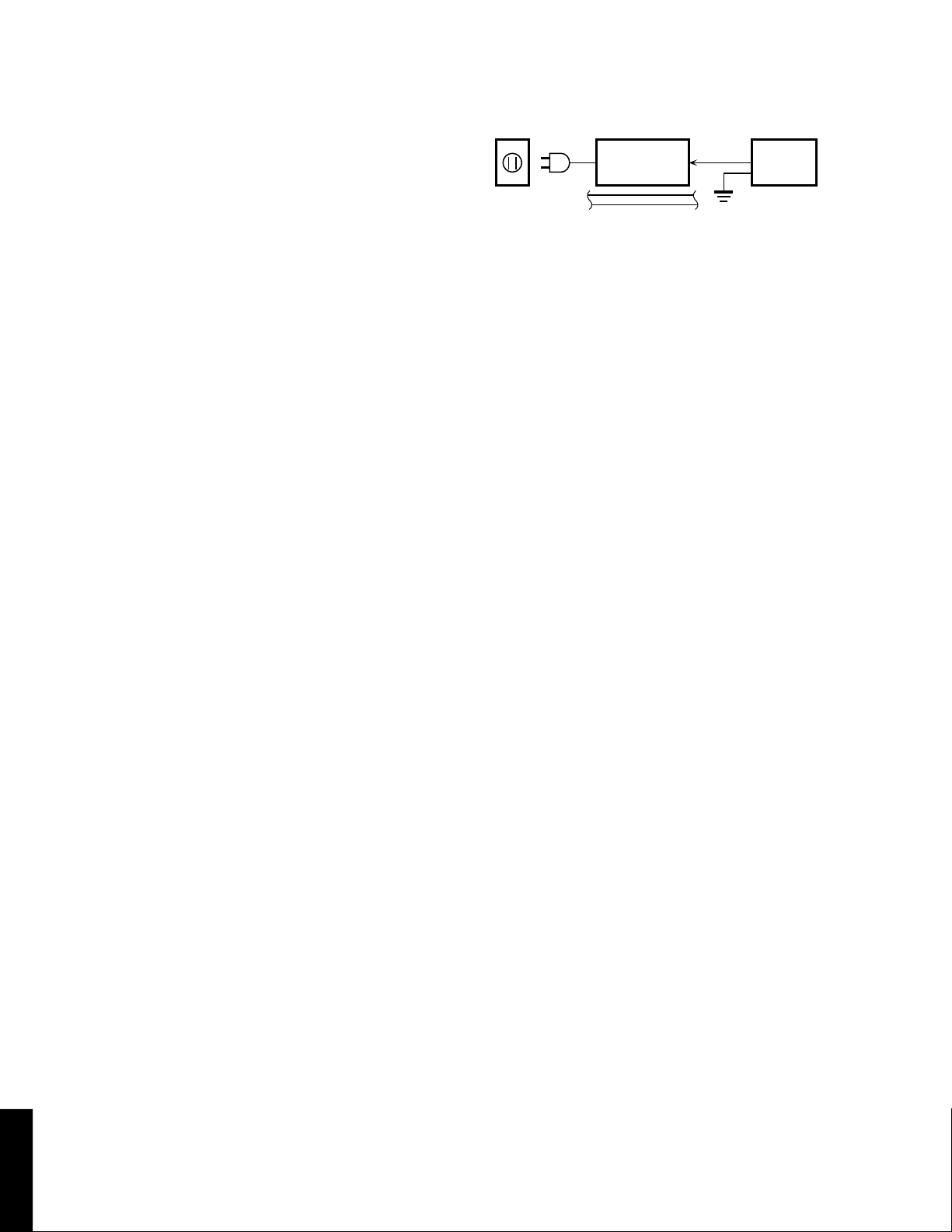

WALL

OUTLET

EQUIPMENT

UNDER TEST

AC LEAKAGE

TESTER OR

EQUIVALENT

INSULATING

TABLE

■TO SERVICE PERSONNEL

1. Critical Components Information

Components having special characteristics are marked Zand

must be replaced with parts having specifications equal to

those originally installed.

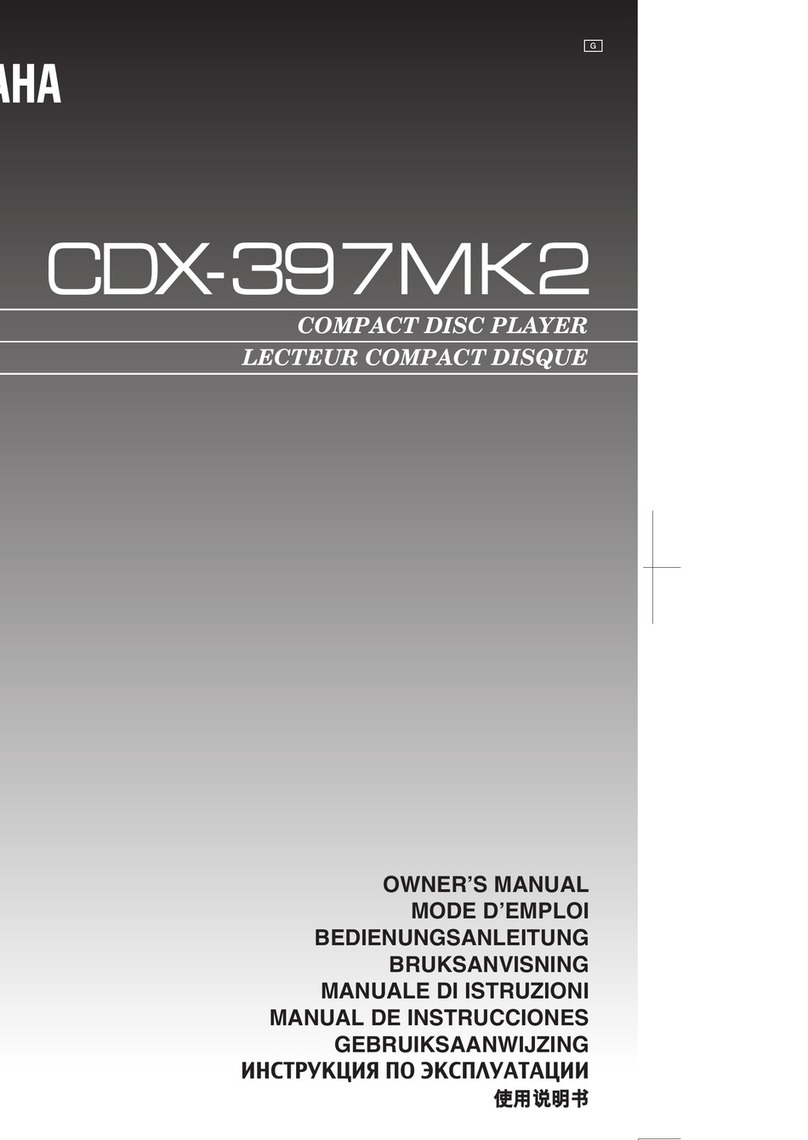

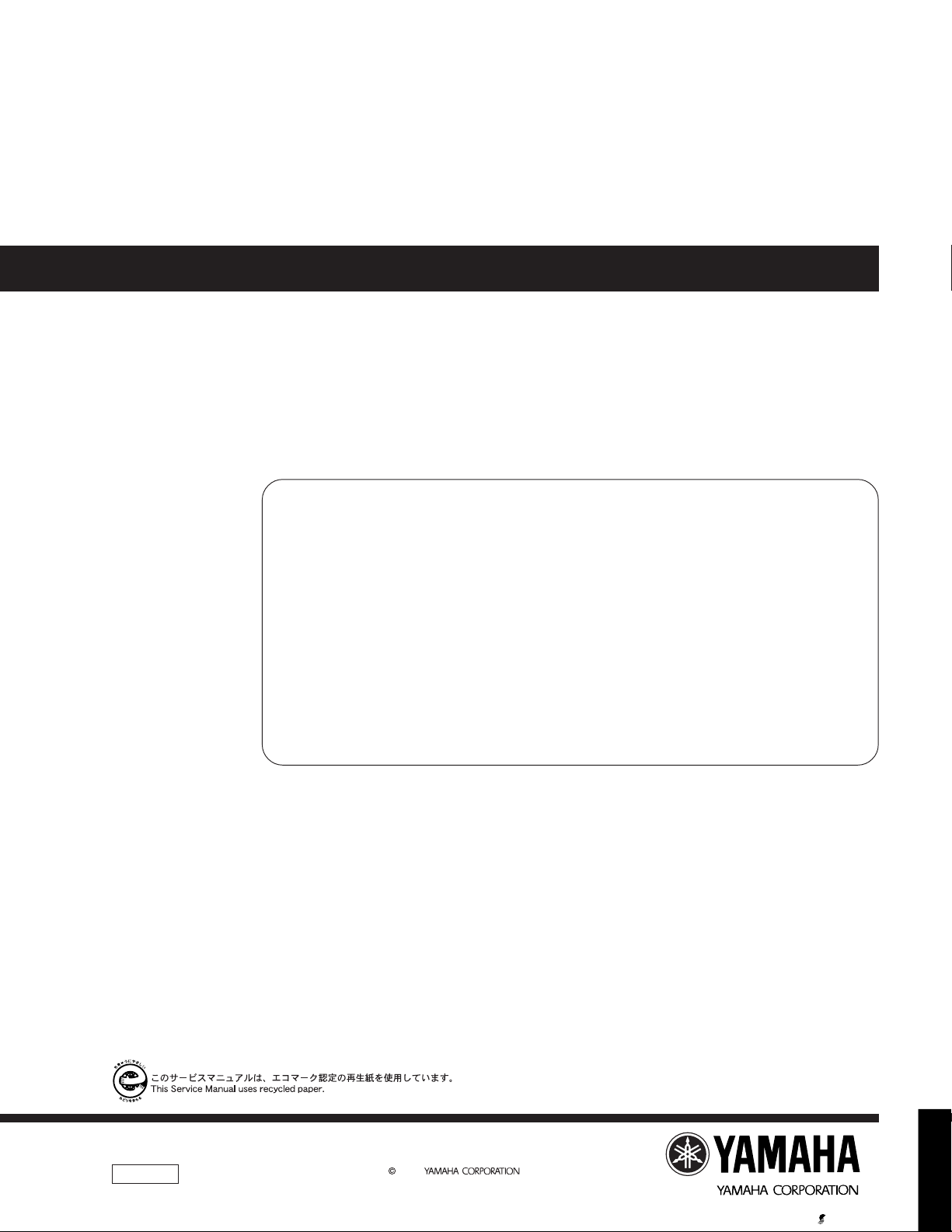

2. Leakage Current Measurement (For 120V Models Only)

When service has been completed, it is imperative to verify

that all exposed conductive surfaces are properly insulated

from supply circuits.

●Meter impedance should be equivalent to 1500 ohms shunted

by 0.15µF.

●Leakage current must not exceed 0.5mA.

●Be sure to test for leakage with the AC plug in both polari-

ties.

WARNING: Laser Safety

This product contains a laser beam component. This component may emit invisible, as well as visible radiation,

which may cause eye damage. To protect your eyes and skin from laser radiation, the following precautions must be

used during servicing of the unit.

1) When testing and/or repairing any component within the product, keep your eyes and skin more than 30 cm away from

the laser pick-up unit at all times. Do not stare at the laser beam at any time.

2) Do not attempt to readjust, disassemble or repair the laser pick-up, unless noted elsewhere in this manual.

3) CAUTION: Use of controls, adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

WARNING: CHEMICAL CONTENT NOTICE!

The solder used in the production of this product contains LEAD. In addition, other electrical/electronic and/or

plastic (where applicable) components may also contain traces of chemicals found by the California Health and

Welfare Agency (and possibly other entities) to cause cancer and/or birth defects or other reproductive harm.

DO NOT PLACE SOLDER, ELECTRICAL/ELECTRONIC OR PLASTIC COMPONENTS IN YOUR MOUTH FOR ANY

REASON WHATSOEVER!

Avoid prolonged, unprotected contact between solder and your skin! When soldering, do not inhale solder fumes or

expose eyes to solder/flux vapor!

If you come in contact with solder or components located inside the enclosure of this product, wash your hands

before handling food.

Laser Emitting conditions:

1) When the Top Cover is removed, and the STANDBY/ON SW is turned to the "ON" position, the laser component will emit

a beam for several seconds to detect if a disc is present. During this time (5-10 sec.) the laser may radiate through the

lens of the laser pick-up unit. Do not attempt any servicing during this period!

If no disc is detected, the laser will stop emitting the beam. When a disc is loaded, you will not be exposed to any laser

emissions.

2) The laser power level can be adjusted with the VR on the pick-up PWB, however, this level has been set by the factory

prior to shipping from the factory. Do not adjust this laser level control unless instruction is provided elsewhere in this

manual. Adjustment of this control can increase the laser emission level from the device.

All of the P.C.B.s installed in this unit and solder joints are soldered using the lead free solder.

Among some types of lead free solder currently available, it is recommended to use one of the following types for the repair

work.

• Sn + Ag + Cu (tin + silver + copper)

• Sn + Cu (tin + copper)

• Sn + Zn + Bi (tin + zinc + bismuth)

Caution:

As the melting point temperature of the lead free solder is about 30°C to 40°C (50°F to 70°F) higher than that of the lead solder, be sure

to use a soldering iron suitable to each solder.

About Lead Free Solder