4

Manual

GTS-1000MZ - EN -

D09-GV09020-01

www.vilagrancha.com

1. Safety instructions and regulations regarding health and safety during operation

1.1 Responsibility

• TheGTS1000MZwoodchippermayonlybeoperatedbypersonsovereighteenyearsofage,neverunderinuenceofdrugsand/

or alcohol and familiar with the safety rules and the operation manual. First and foremost, users must be able to stop the machine

immediately.

• Users are responsible for all damage caused to a third party.

• The GTS1000MZ woodchipper is only to be used for the purpose mentioned in this instruction booklet. If the machine is used for

any other purpose than described, the warranty and the responsibility of both the manufacturer and distributor will be null and void.

• The warranty will also be invalidated in the case of unauthorized intervention on the machine and whenever the safety instructions,

as described in the following enclosures, are not followed.

• The user should be aware of the rules and regulations concerning the environment and noise levels. When using the GTS1000MZ

woodchipper it is necessary for the user to wear personal protective equipment against noise (ear protection). Woodchipping has

to be stopped every hour for at least 15 minutes. During these intervals, which are necessary in order to avoid the user being ex-

posed to too much noise, the user should not be exposed to noise.

• IncaseofprofessionaluseoftheGTS1000MZwoodchipper,theinstructormustprovidetheuserofthechipperwithsufcient(writ-

ten) instructions to guarantee a safe use.

1.2 Instructions for safety during use

Usersmustwearheavy-dutyfootwearandappropriate,wellttingtrousers.Safetygogglesandhearprotectionaremandatory.Donot

wear loose clothes, or clothes with strings or ties. Long branches could lash into your face, so keep at a distance and always wear face

protection. Wear gloves whenever dealing with the blades.

Defects must be corrected before use. Use only ORIGINAL spare parts for your own safety and validity of the warranty.

Check before every use at least the following:

• Loose bolts and nuts

• Damagedrubberapsintheinputtube–changethemiftheyaredamagedorworn.

• Oil level in the engine

• Cracks in the plating and/or failed weldings

• Cracked or damaged wiring

• Infeed tube and rotor should be empty

• The user is responsible for the safety of all persons within a radius of 12 m. Mark off an area at least 3 meters wide and 12 meters

long on the output side. Use red/white ribbons for marking the danger zone. If your machine is equipped with a turnable output tube,

each time you change the direction of the output tube, the marked area needs to be adjusted accordingly. Always stand clear of the

discharge zone when operating the machine.

• Do not allow processed material to build up in the discharge zone; this may prevent proper discharge and

can result in kickback of material through the feed intake opening.

• See that the machine stands horizontal and check the tire pressure regularly (minimum 1.5 bar, maximum

1.9 bar).

• The engine should only be run outdoors or in well-ventilated spaces. The smoke from the exhaust is very

toxic and prolonged inhalation can be fatal.

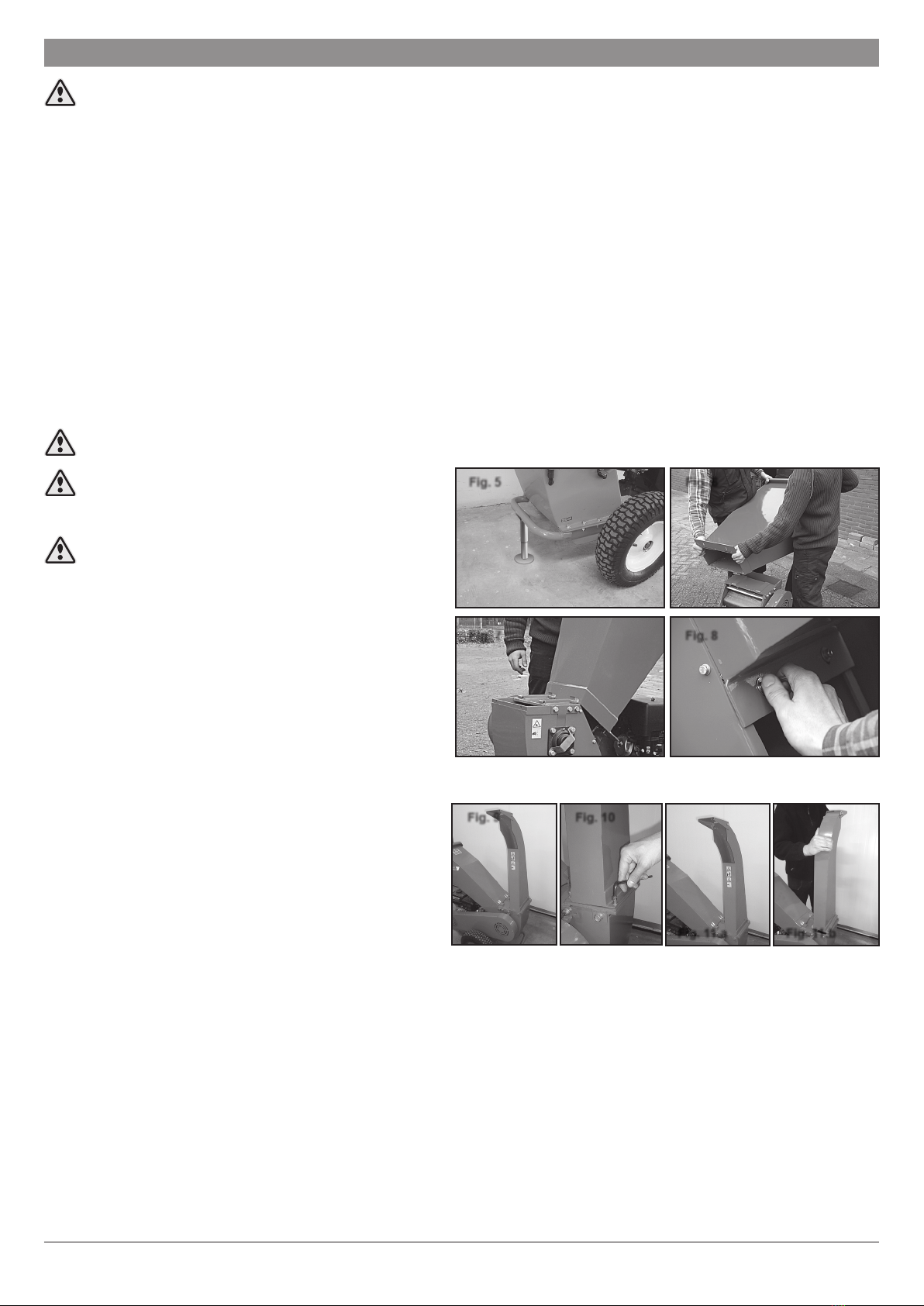

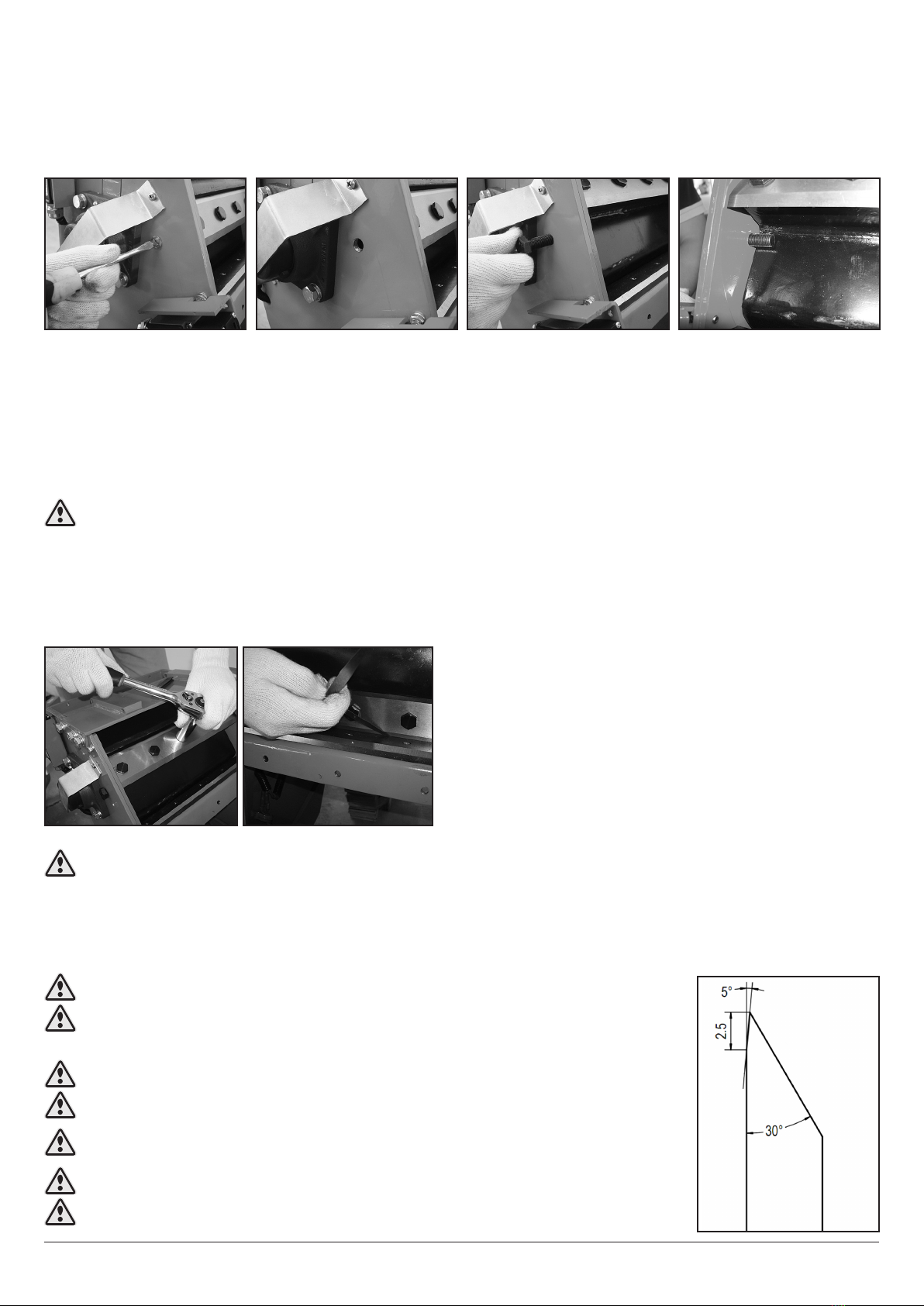

•Thefueltankmustbelledusingafunnel(Fig.1),alwaysintheopenairorinawell-ventilatedspace,with

theengineswitchedoffandhavingcooleddown.Fuelishighlyammable.Donotsmokeorlightare.Use

onlyanapprovedcontainer.Alwaysreplaceandsecurelytightenthefuelcapafterrelling.

• If fuel is spilled, do not attempt to start the engine, but move the machine away from the area of spillage

before starting. Always clean up spilled fuel.

• Place the machine in such a way that the exhaust fumes are blown away from the operator position. If

needed move the machine.

• Do not operate the machine on a paved or gravel surface where ejected material could cause injury.

•Onlyoperatethemachineinanopenspace(e.g.notclosetoawallorotherxedobject).

• Never leave the machine unattended. If you leave the machine, stop the engine (Fig. 2) and (if applicable)

remove the key (Fig. 3) from the contact or disconnect the spark plug wire.

• Assemble the machine completely before use. Never use the machine without the infeed or outfeed tube mounted on the machine.

If the machine is equipped with a turnable output tube, never remove the turnable output. Always assemble the belt cover and the

handle. All these parts assure that it is possible to work on a safe and easy way with the machine.

•

If the blades hit a foreign object (anything except wood), or if the machine starts making unusual noises and/or shaking unusually, you

must switch off the machine at once to stop the blades rotating. Switch off the engine and take the machine to the recommended dealer.

• The blades are blunt when the material isn’t smoothly pulled into the machine anymore. The blades should be turned, grinded or

replaced. Blunt blades increase the force on the rotor exponential and can cause broken parts which are not covered by warranty.

•

Keep your face and body as far as possible from the input tube. While feeding the machine do not stand higher than the bottom of the

wheels. Keep your balance and make sure your feet have grip on the soil. Do not bent forwards. Do not allow hands or any other part of

thebodyorclothinginsidetheinfeedoroutfeedtube.Stayawayfrommovingparts.Replacewarningsignsifdamagedornotsufciently

legible.

• It is prohibited to feed any other material into the machine (e.g. metal, stones, plastics or any other material) than those mentioned in the manual.

• If the machine becomes clogged at the input or output tube, shut-off the engine and disconnect the spark plug wire or remove the key

(if applicable) before cleaning the debris. Keep the power source clear of debris and other accumulations to prevent damage to the

engineorpossiblere.Rememberthatoperatingthestartingmechanismontheenginewillcausethecuttingmeanstomove.

• Do not tilt the machine while the engine is running.

Fig. 1

Fig. 3

Fig. 2