EAS20090

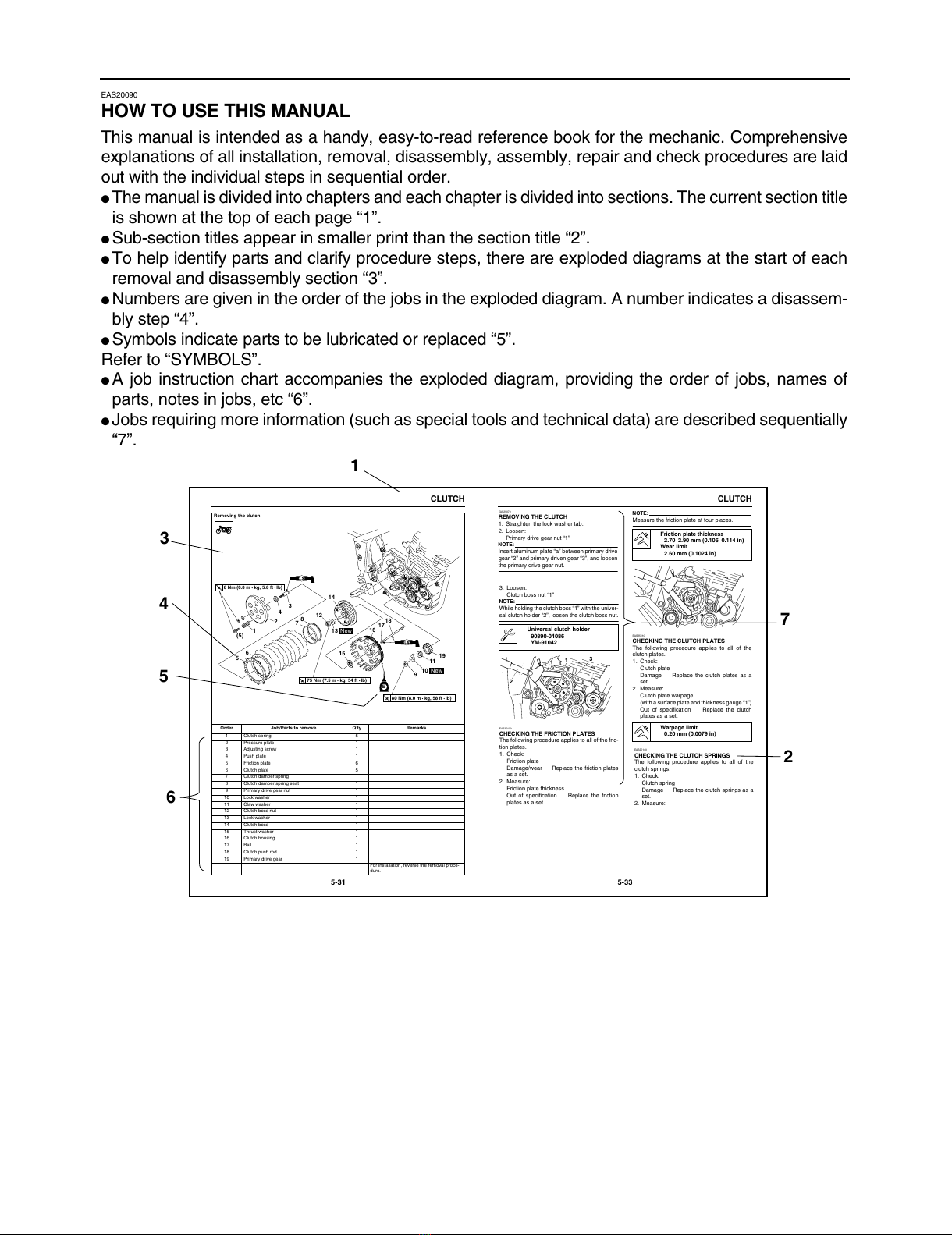

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive

explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid

out with the individual steps in sequential order.

●The manual is divided into chapters and each chapter is divided into sections. The current section title

is shown at the top of each page “1”.

●Sub-section titles appear in smaller print than the section title “2”.

●To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each

removal and disassembly section “3”.

●Numbers are given in the order of the jobs in the exploded diagram. A number indicates a disassem-

bly step “4”.

●Symbols indicate parts to be lubricated or replaced “5”.

Refer to “SYMBOLS”.

●A job instruction chart accompanies the exploded diagram, providing the order of jobs, names of

parts, notes in jobs, etc “6”.

●Jobs requiring more information (such as special tools and technical data) are described sequentially

“7”.

7

2

CLUTCH

5-31

Removing the clutch

Order Job/Parts to remove Q’ty Remarks

1 Clutch spring 5

2 Pressure plate 1

3 Adjusting screw 1

4 Push plate 1

5 Friction plate 6

6 Clutch plate 5

7 Clutch damper spring 1

8 Clutch damper spring seat 1

9 Primary drive gear nut 1

10 Lock washer 1

11 Claw washer 1

12 Clutch boss nut 1

13 Lock washer 1

14 Clutch boss 1

15 Thrust washer 1

16 Clutch housing 1

17 Ball 1

18 Clutch push rod 1

19 Primary drive gear 1

For installation, reverse the removal proce-

dure.

New

New

E

T

R

.

.

8 Nm (0.8 m •kg, 5.8 ft •Ib)

T

R

.

.

75 Nm (7.5 m •kg, 54 ft •Ib)

T

R

.

.

80 Nm (8.0 m •kg, 58 ft •Ib)

1

2

5

6

7812

13

15

16 17

910

11

19

18

14

3

4

(5)

3

4

5

6

1

CLUTCH

5-33

EAS25070

REMOVING THE CLUTCH

1. Straighten the lock washer tab.

2. Loosen:

Primary drive gear nut “1”

NOTE:

Insert aluminum plate “a” between primary drive

gear “2” and primary driven gear “3”, and loosen

the primary drive gear nut.

3. Loosen:

Clutch boss nut “1”

NOTE:

While holding the clutch boss “1” with the univer-

sal clutch holder “2”, loosen the clutch boss nut.

EAS25100

CHECKING THE FRICTION PLATES

The following procedure applies to all of the fric-

tion plates.

1. Check:

Friction plate

Damage/wear Replace the friction plates

as a set.

2. Measure:

Friction plate thickness

Out of specification Replace the friction

plates as a set.

NOTE:

Measure the friction plate at four places.

EAS25110

CHECKING THE CLUTCH PLATES

The following procedure applies to all of the

clutch plates.

1. Check:

Clutch plate

Damage Replace the clutch plates as a

set.

2. Measure:

Clutch plate warpage

(with a surface plate and thickness gauge “1”)

Out of specification Replace the clutch

plates as a set.

EAS25140

CHECKING THE CLUTCH SPRINGS

The following procedure applies to all of the

clutch springs.

1. Check:

Clutch spring

Damage Replace the clutch springs as a

set.

2. Measure:

Universal clutch holder

90890-04086

YM-91042

2

13

Friction plate thickness

2.70—2.90 mm (0.106—0.114 in)

Wear limit

2.60 mm (0.1024 in)

Warpage limit

0.20 mm (0.0079 in)