4.SensorUnitAdjustment

Adjustmentisrequiredwhentheunitisdetachedorreplaced.

■Keysensorunitadjustment

[Standard]

[Procedure]

■Hammersensorunitadjustment

[Standard]

[Procedure]

1) Turnonthepowerswitchwhilepressingthe[REC]and[PLAY]togetintoTestMode.

2) Select"t04"toactivateHammerSensorTest.

Pleasereferto6.TestMode(Page15).

3) RotatetheadjustmentdialtoadjusttheM2position.

[AdjustmentProcedure]

1) LoosenLonglockscrew(A)

2) LoosenLockscrew(B)

3)

4) TightenLockscrew(B)

5) TightenLonglockscrew(A)

■Pedalsensorunitadjustment

[Damperpedaldetectionpositionadjustment]

[Shiftpedalsensor/Sosutenutopealsensordetectionpositionadjustment]

Adjustmentisrequiredwhentheunitisdetachedforactionregulation.

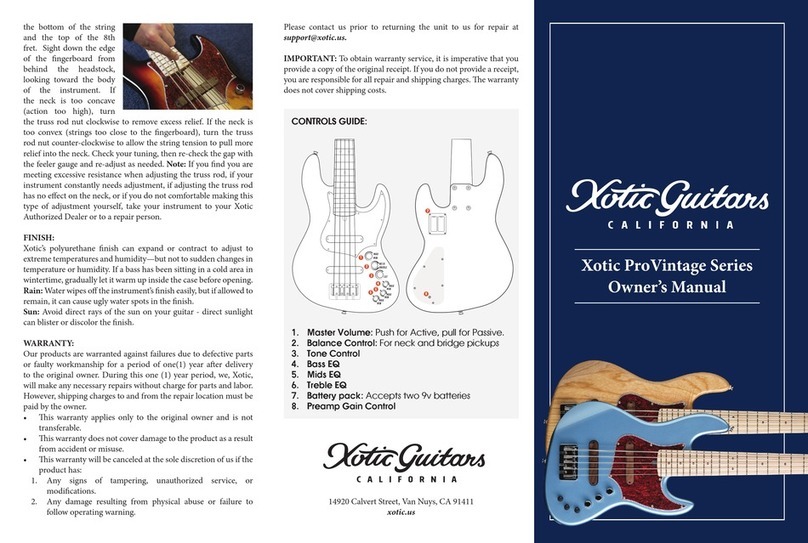

Fig.6

a

Adjustmentscrews

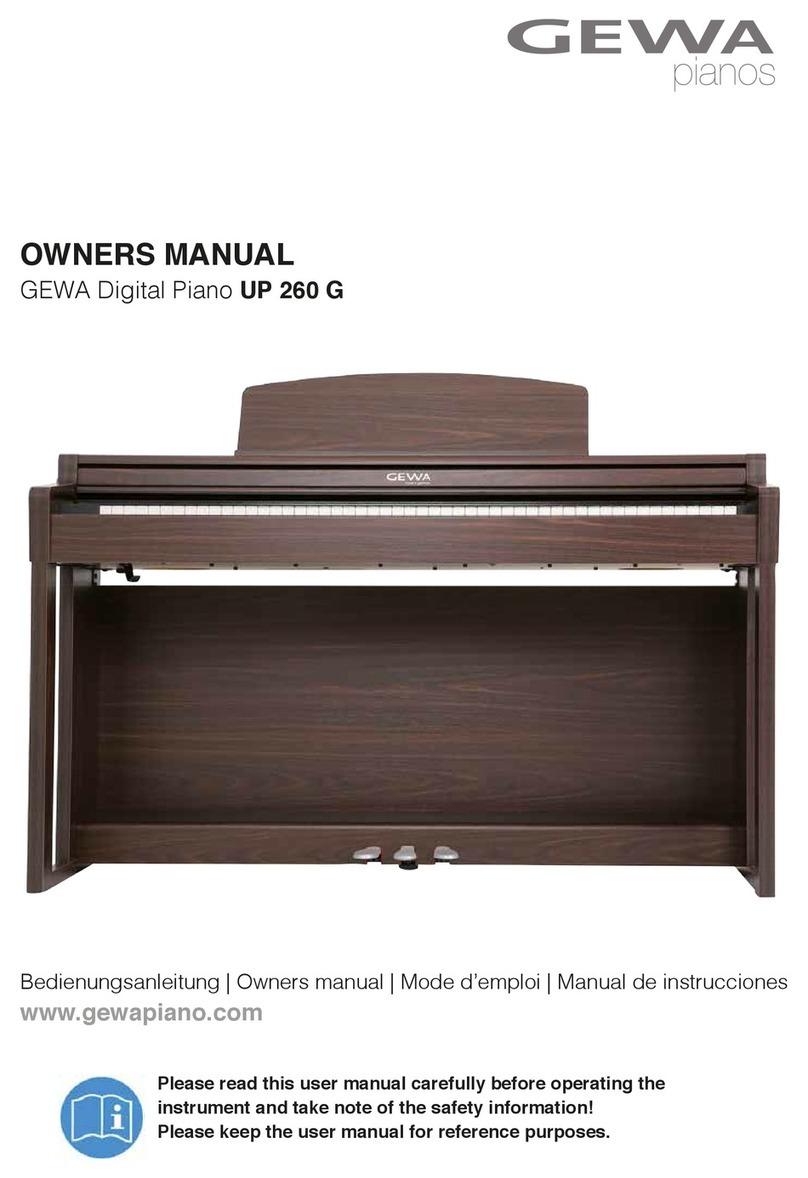

Fig.7

GrandPiano

Adjustmentdial

(A)

(C)

(B)

Lockplate

Adjustthegapbetweenthebottomsurfaceofablackkey

locatednearthesensorbracketandtheuppersurfaceofthe

keysensorunitto3.0mmto5.0mmwhendepressingthe

blackkeytothelowestpoint,andthegapbetweenthe

keyboardandKeysensorrailsothatitisparallel,alsowhen

depressingtheblackkeytothelowestpoint.(Fig.6)

Adjustfromthebottomofthekeyboardwith2adjustment

screwstomakeagapofappropriatesize.

Adjustmentspots:Sensorbrackets:4

Adjustmentscrews:2each(Fig.7)

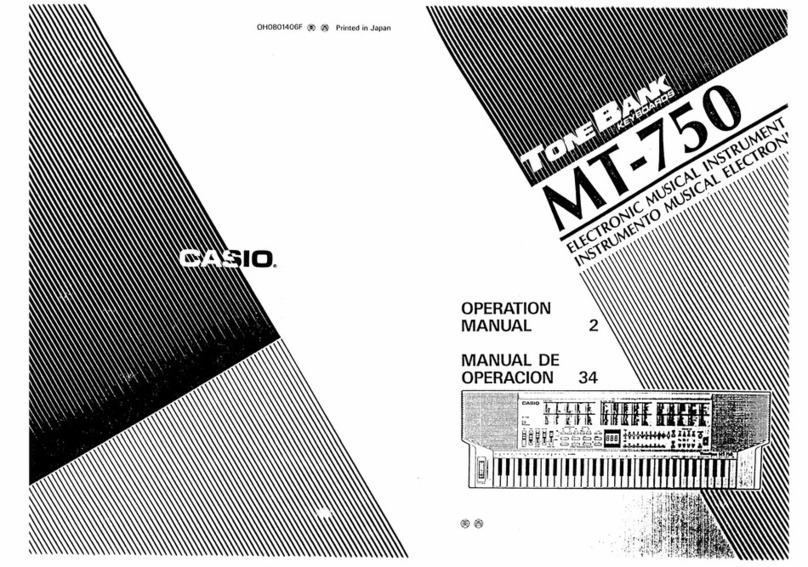

M2Buzzersoundpositionis0.5mmto2.5mmbeforeshankstoppingposition.(Fig.8)

DamperpedaldetectionpositionadjustmentshallbedonewithregisteringHalfpointpositioninthe

DamperPedalCalibrationmode.Pleasereferto5.CalibrationMode(Page12).

Shift/Sosutenutopedalsensordetectionpositionadjustmentshallbedonewiththetestmode

buzzersoundingpositions.Pleasereferto6.TestMode(Page15).

Hammershankstoppingpositionto5mm–6mmfromthestrings

M2:Shankstoppingposition0.5mmto2.5mm

Fig.8

Longlockscrew(A)

Hammersensorheightadjuster(C)

Lockscrew(B)

RotateHammersensorheightadjuster(C)toadjusttheM2position.

‐10‐