9AB-6464

Manually Opening/Closing Valve

CAUTION

•To manually open or close the valve, be

sure to disconnect the ACTIVAL from the

power supply (24 V AC). If the valve is

manually opened or closed with the power

applied, the actuator may be damaged.

•Never rotate the joint out of “0” to “100”

range of the scale.

Before manually opening or closing the ACTIVAL, make

sure it is disconnected from the power supply.

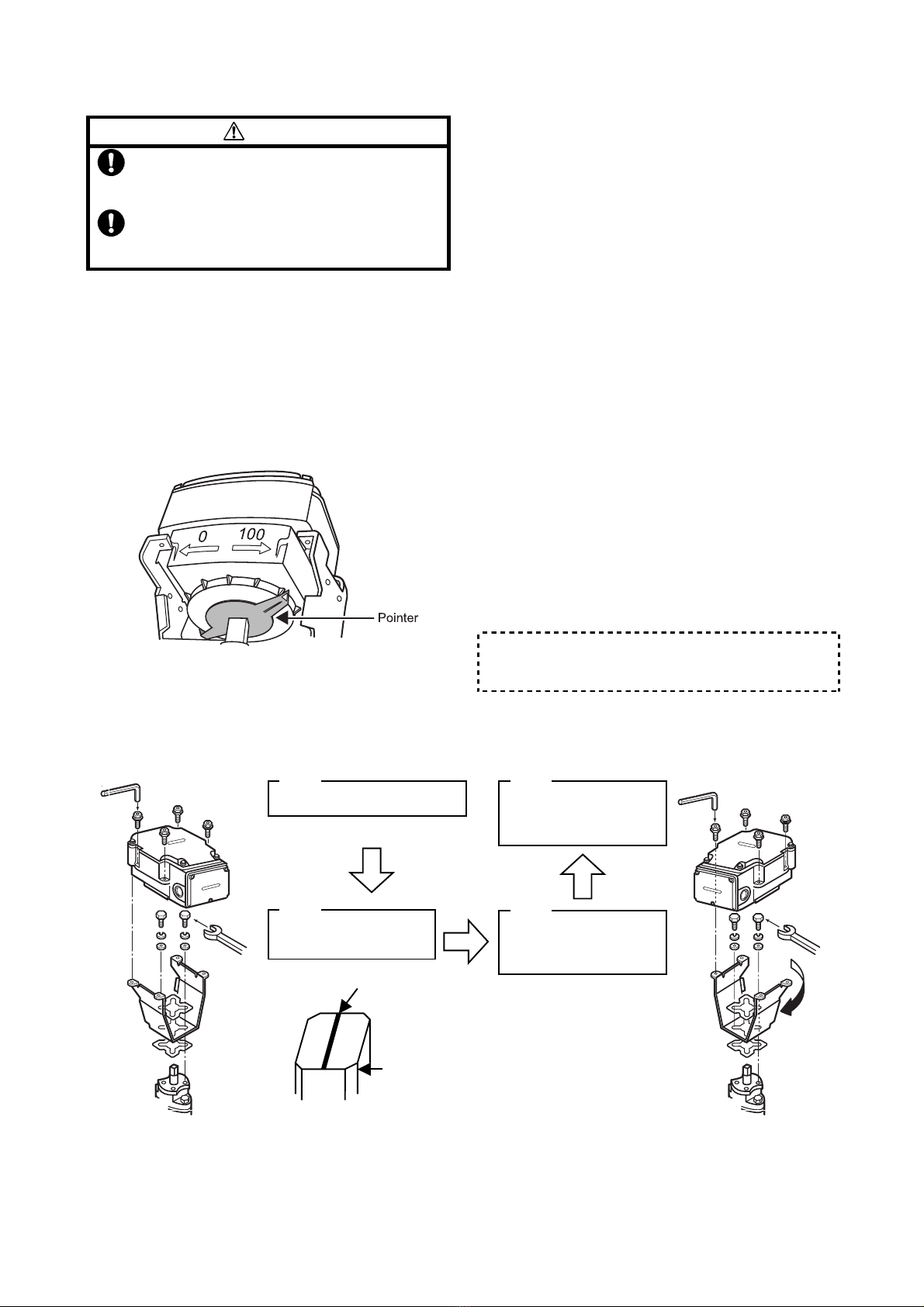

As shown in Fig. 7, hold the joint with a tool such as a

hexagonal wrench, and turn the joint slowly toward the

position to set up.

Figure 7. Manual open/close operation

Auxiliary Switch / Auxiliary Potentiometer

(Optional)

CAUTION

•The auxiliary switch and the auxiliary poten-

tiometer are installed on site. (See Fig. 15.)

Refer to the instructions attached to them.

•Do not open the top cover except when ad-

justing the auxiliary switch or auxiliary poten-

tiometer.

•Do not put a load on the cover.

Wiring

CAUTION

•Disconnect power supply before performing

any wiring.

•This product is designed for 24 V AC power

supply voltage. Do not apply mains power.

•For correct wiring of 4-20 mA DC input and

2-10 V DC input, refer to Figs. 12 to 14 and

make sure the polarity of power supply and

2-10 V DC output. Incorrect wiring may

result in PCB (printed circuit board) burnout.

•To prevent equipment damage, cover the

actuator except during wiring work.

Wiring precautions

1) Do not apply 24 V AC to the terminals 4, 5 and 6.

(Max. applicable voltage: 5 V DC)

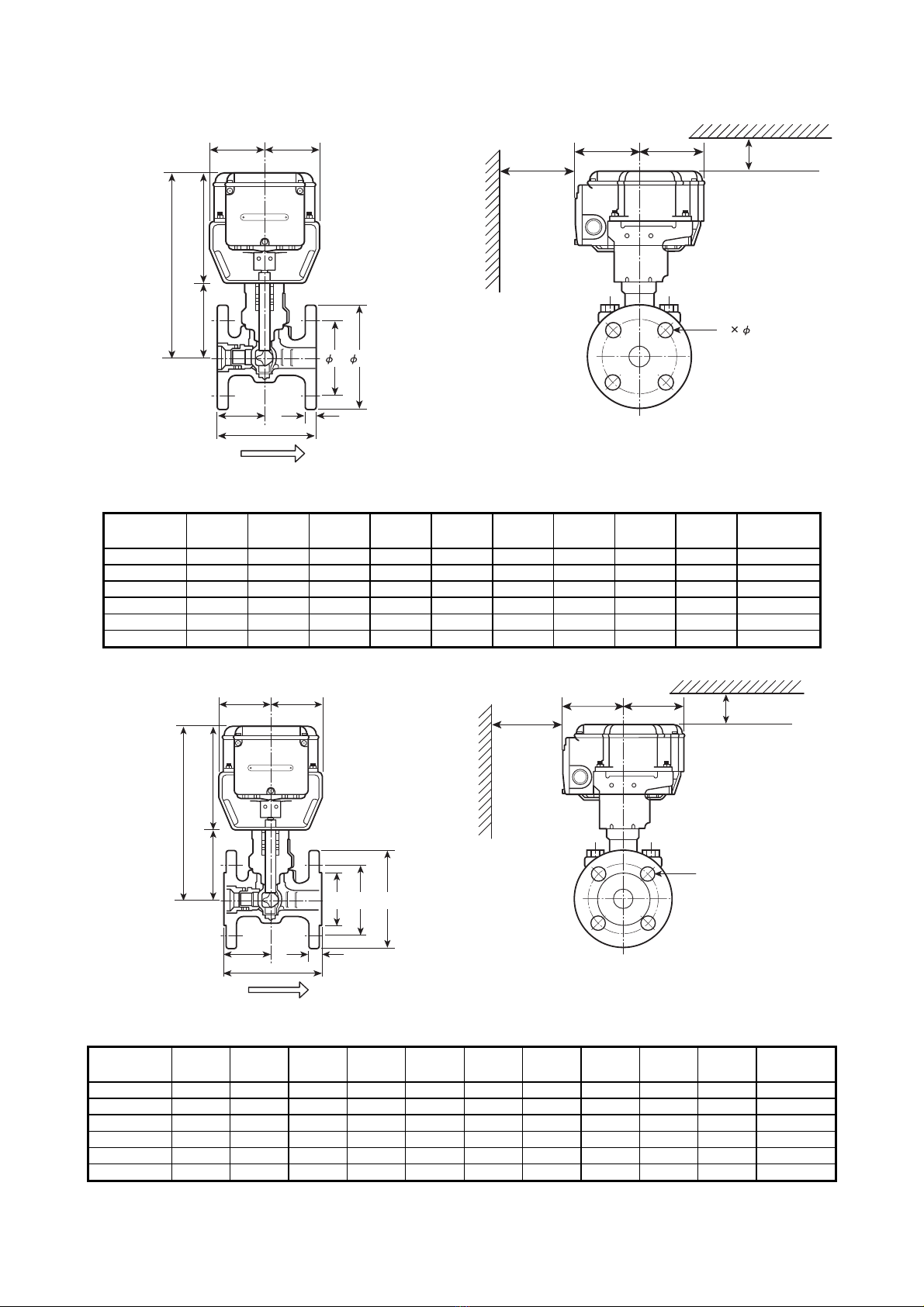

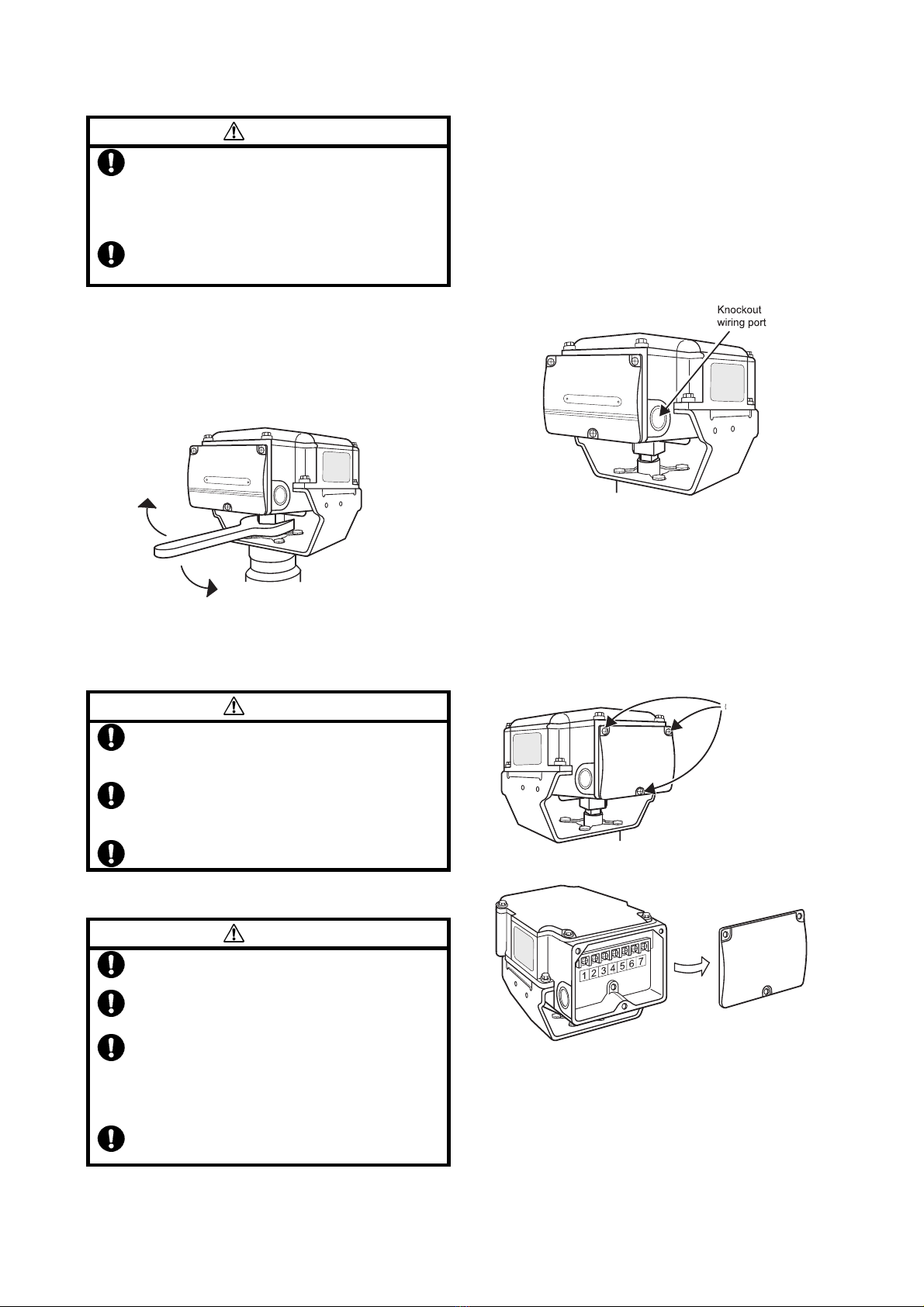

2) To lead the wires into the actuator, cut out a knockout

hole for a wiring port. There are two knockout holes

on the bilateral sides of the actuator terminal block:

one φ22 mm knockout hole on each side. Select a

knockout hole according to the conduit mounting

direction and cut it out by lightly knocking with a

screwdriver. (Refer to Fig. 8 )

Figure 8. Knockout hole for wiring port

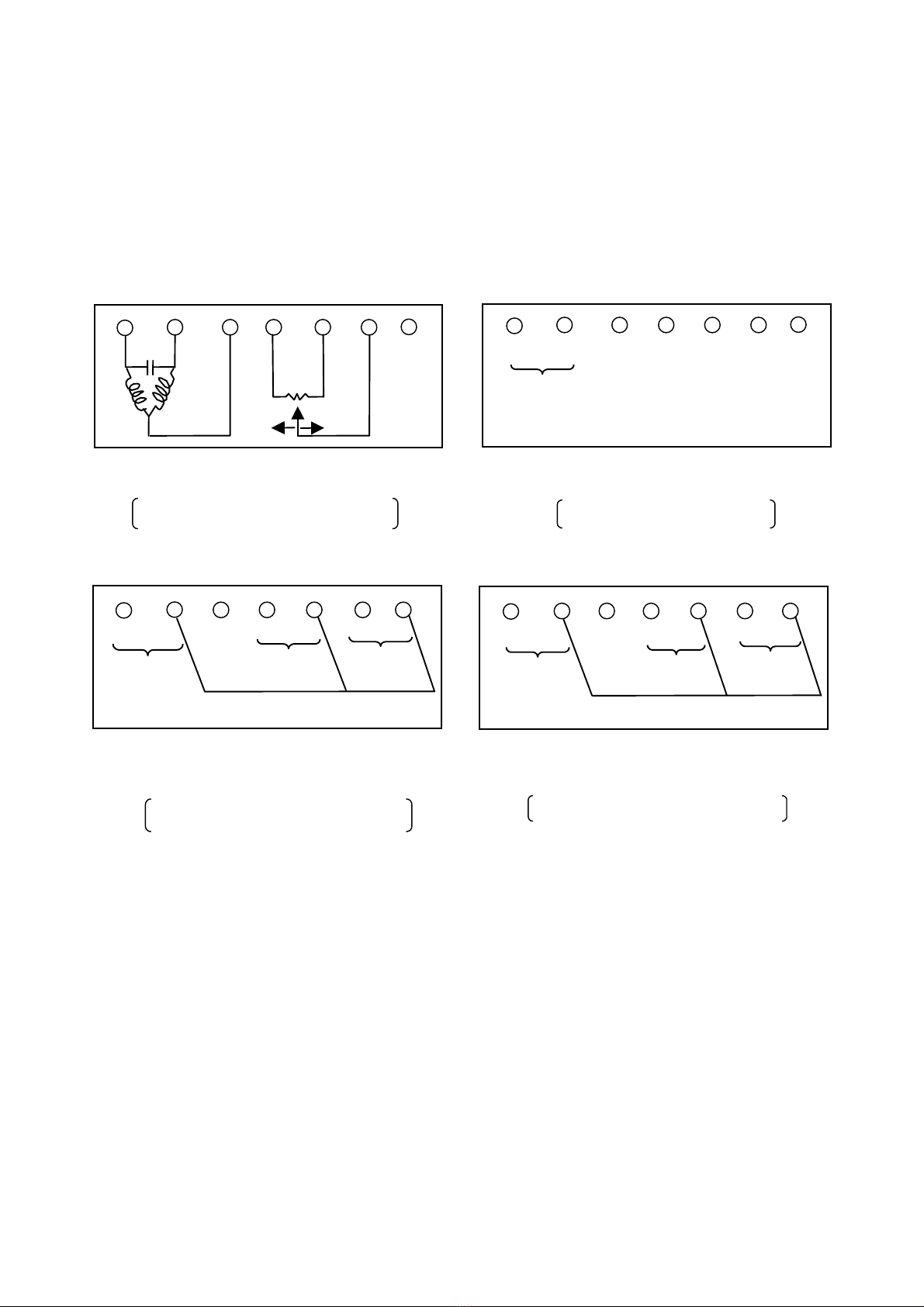

3) Correctly connect the wiring to the terminals with M3.5

screws, referring to the wiring terminal diagrams

shown in Figs. 10 to 13 and the wiring examples

shown in Fig. 14 . (For the wiring of the auxiliary switch

or the auxiliary potentiomenter, refer to Fig. 15.)

4) When the ACTIVAL is used in a high-humidity

environment or outdoors, use a water-proof connector.

Figure 9. Terminal cover removal

Unscrew the three screws (M4 ×10) to remove the

terminal cover. (See Fig. 9.)

1. Remove

these screws

2. Remove terminal cover