2.1 Check and change of voltage

Fig. 2-1

Table 2

Table 1

2.1.2 Changing of set voltage

2.1.1 Checking power supply voltage

2.Installation

power supply

voltage fuse capacity part number

of fuse

100 - 110 V 2 A 1070020

200 - 240 V 1 A 0010912

power

supply

voltage

voltage of

transformer

terminal

description

of voltage

indicate

plate

part number

of power

indicate

plate

100V 100V 100V 000805

200V 200V 200V 000806

220V 220V 220V 000742

240V 240V 240V 393120

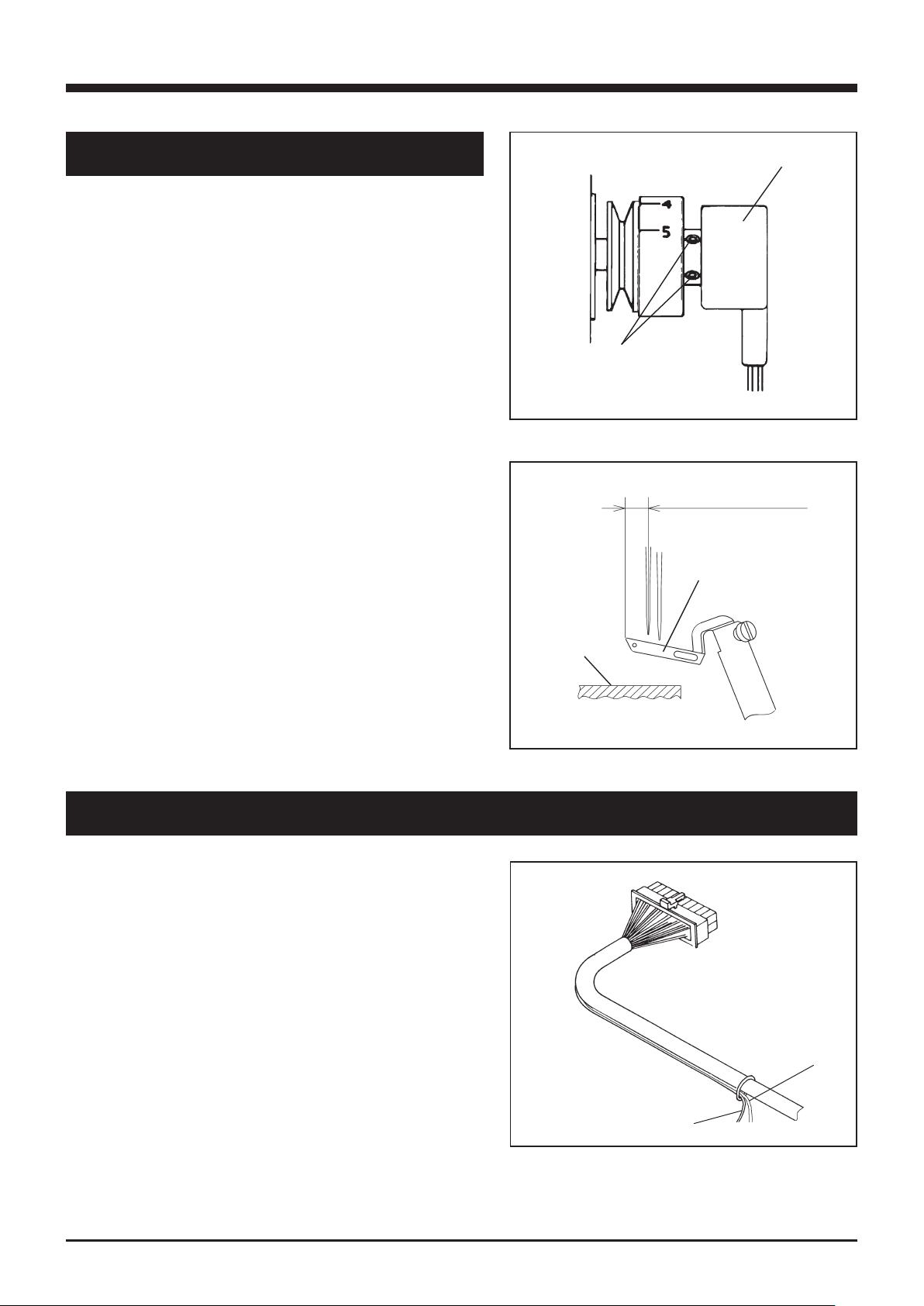

If the power source voltage is different from

the set voltage of the control box, remove the

cover of the control box and change the position

of the tap on the transformer terminal to the

proper one. (See Table. 1) Change also the fuse

and the voltage panel to ones applicable to the

power supply voltage, referring to Tables 1 and

2.

Before operation, check that the power supply

voltage used is the same as the voltage printed

on the control box. (It is printed on the plate

on the rear of the control box.)

At shipment, the voltage printed on the control

box is 220 V and the usable range is 220 to 240 V.

If using this BT43 device at a voltage other

than this range, please contact our technician

in our agencies.

If you have your own technician of electronics,

take the following steps.

change the position

depending on voltage

Make this work before installing the control box to the

table.

If taking wrong steps, the control box can be damaged.

Be sure to follow proper steps.

Before starting the work, pull the power

plug out of the control box and wait more

than 5 minutes.