目次

Cautions in Using With Safety ..............................................................1

Explanation..................................................................................................................1

Table of Illustrated Symbols .........................................................................................2

Fundamental Matters of “WARNING!” and “CAUTION!” ...............................................3

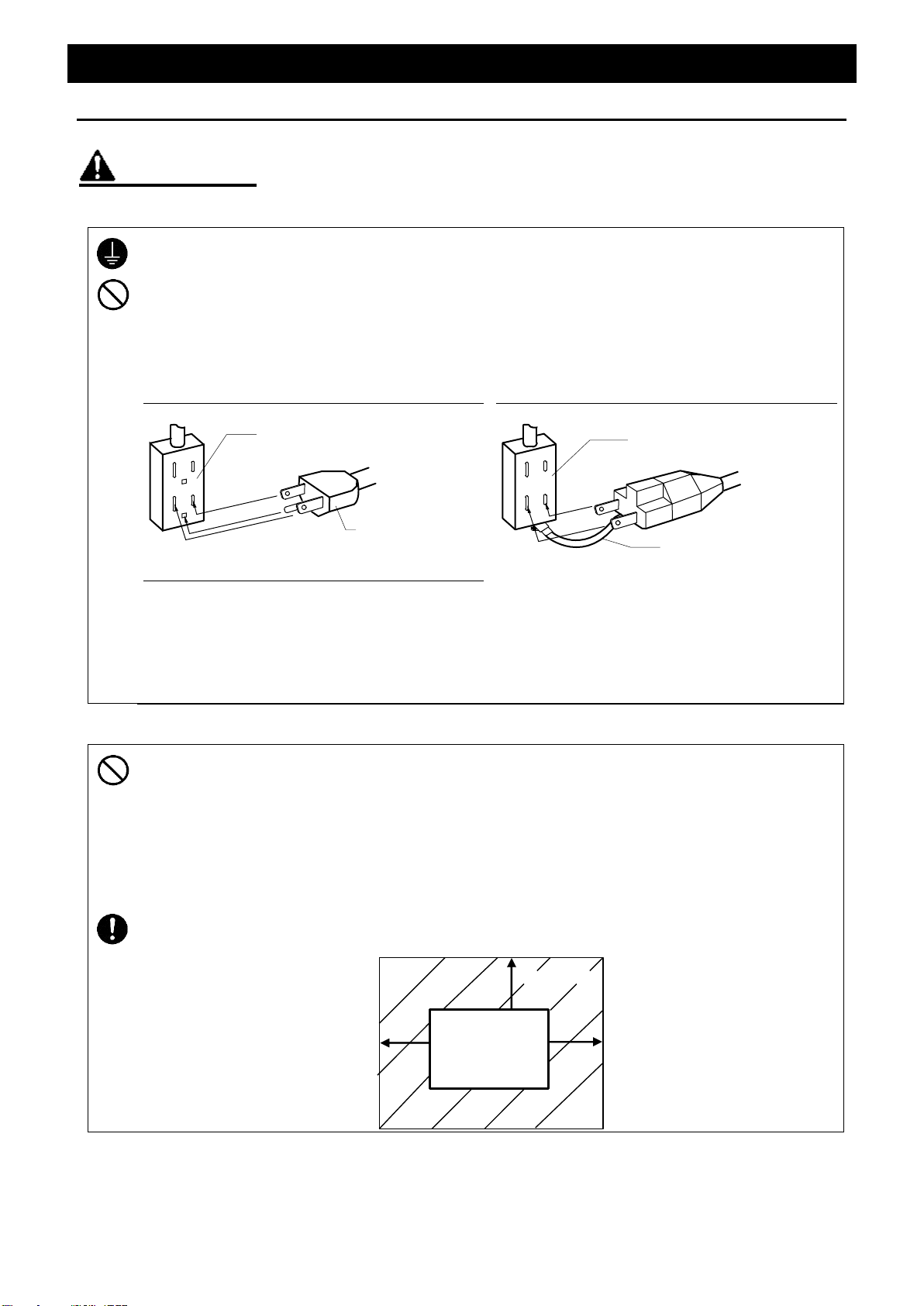

Before Using this unit............................................................................4

Requirements for Installation........................................................................................4

Requirements for Installation........................................................................................5

Requirements for Installation........................................................................................6

Component Names & Functions...........................................................7

Operation Method ..................................................................................8

Preparation for Operation.............................................................................................8

Operation.....................................................................................................................9

Timer Operation method ..............................................................................................9

Timer operation method.............................................................................................10

Handling Precautions ..........................................................................11

Maintenance Method............................................................................13

Daily Inspection and Maintenance..............................................................................13

When not using this unit for long term / When disposing............................................13

In the Event of Failure… ......................................................................14

Trouble Shooting........................................................................................................14

In such cases.............................................................................................................14

After Service and Warranty .................................................................15

Specification.........................................................................................16

Wiring Diagram ....................................................................................17

List of Dangerous Substances............................................................18