Table of Contents

1. Specifications.................................................................................................................................1-2

2. Safety Information..........................................................................................................................3-7

Safety Symbols.................................................................................................................................... 3

Safety Precautions ...........................................................................................................................4-6

Hazardous Material ............................................................................................................................. 7

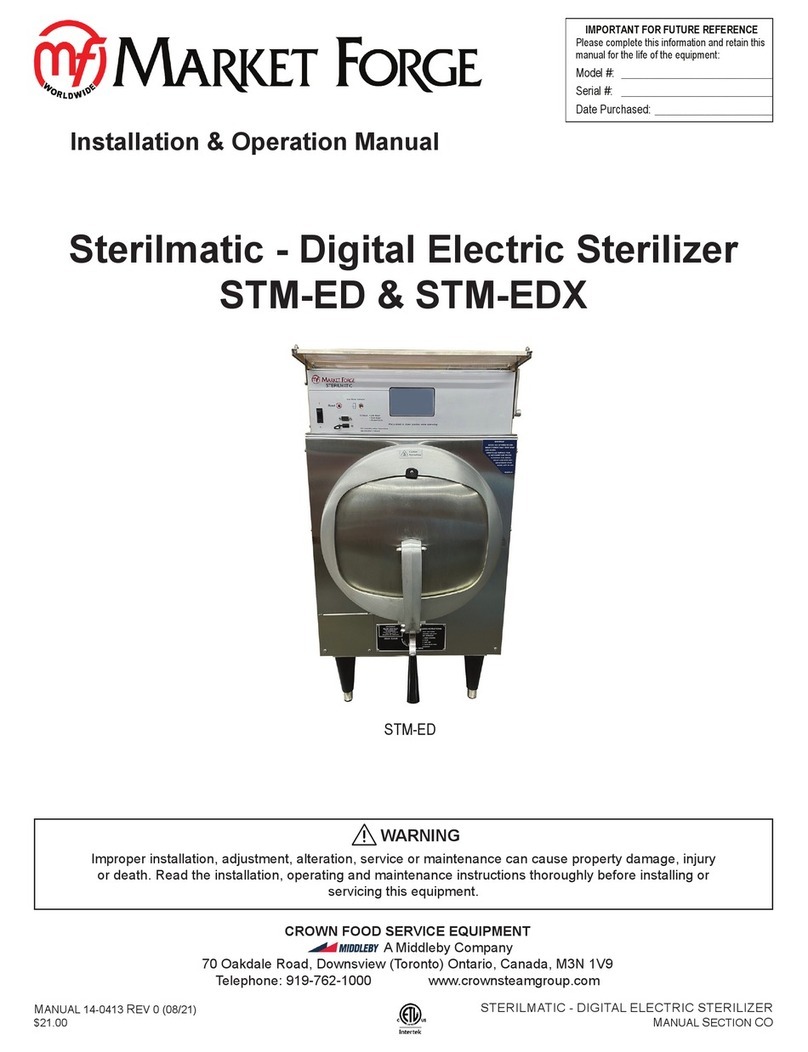

3. Identification of Parts...................................................................................................................8-11

External................................................................................................................................................ 8

Internal............................................................................................................................................9-10

Control Panel..................................................................................................................................... 11

4. Installation...................................................................................................................................12-18

Environmental Requirements.......................................................................................................12-13

Power Requirements......................................................................................................................... 14

Initial Set Up .................................................................................................................................15-18

5. Operational Precautions............................................................................................................19-20

6. Sample Run Examples.................................................................................................................... 21

7. Program “MODE” .......................................................................................................................22-27

“MODE” key Information.................................................................................................................... 22

Display Symbols................................................................................................................................ 23

Flowchart........................................................................................................................................... 24

Setting Sterilization Temperature and Time...................................................................................... 25

Setting Dry Temperature and Time................................................................................................... 26

Special Program Features................................................................................................................. 27

8. Run “MENU” ...............................................................................................................................28-33

Selection of Operation....................................................................................................................... 28

“STERILIZE” Procedure..............................................................................................................29-30

“STERILIZE & DRY” Procedure .................................................................................................31-33

9. Special Control Functions.........................................................................................................34-35

View Parameter during Operation..................................................................................................... 34

Interrupt Program during Operation .................................................................................................. 35

Pressure Relief Switch ...................................................................................................................... 35

Checking chamber temperature during stand-by mode.................................................................... 35

10. Troubleshooting Guide............................................................................................................36-37

Safety................................................................................................................................................. 36

Self-diagnostic Circuitry..................................................................................................................... 36

Error Code List .................................................................................................................................. 36

In case of power failure ..................................................................................................................... 36

Problem Solving Chart....................................................................................................................... 37

11. Wiring Diagram.........................................................................................................................38-39

12. Piping Chart................................................................................................................................... 40

13. Maintenance..............................................................................................................................41-42

Daily Maintenance............................................................................................................................. 41

Weekly Maintenance......................................................................................................................... 41

Monthly Maintenance ........................................................................................................................ 42

14. After Sale Service and Warranty.................................................................................................. 43

Request for Repair ............................................................................................................................ 43

15. Replacement Parts List ................................................................................................................ 44