2

TABLE OF CONTENTS

Thank You……………………………………………...

Safety First……………………………………………...

Building Instructions…………………………………...

Additional Building Materials………………………….

Recommended Electronics………………......................

Kit Contents…………………………………………….

Kit Construction………………………………………..

Paint and Decal Installation…………………………….

Servo and Push Rod Installation………………………..

Setup……………..……………………………………..

General…………………………………………………

Preflight………………………………………………..

First Flight……………………………………………..

Thank You

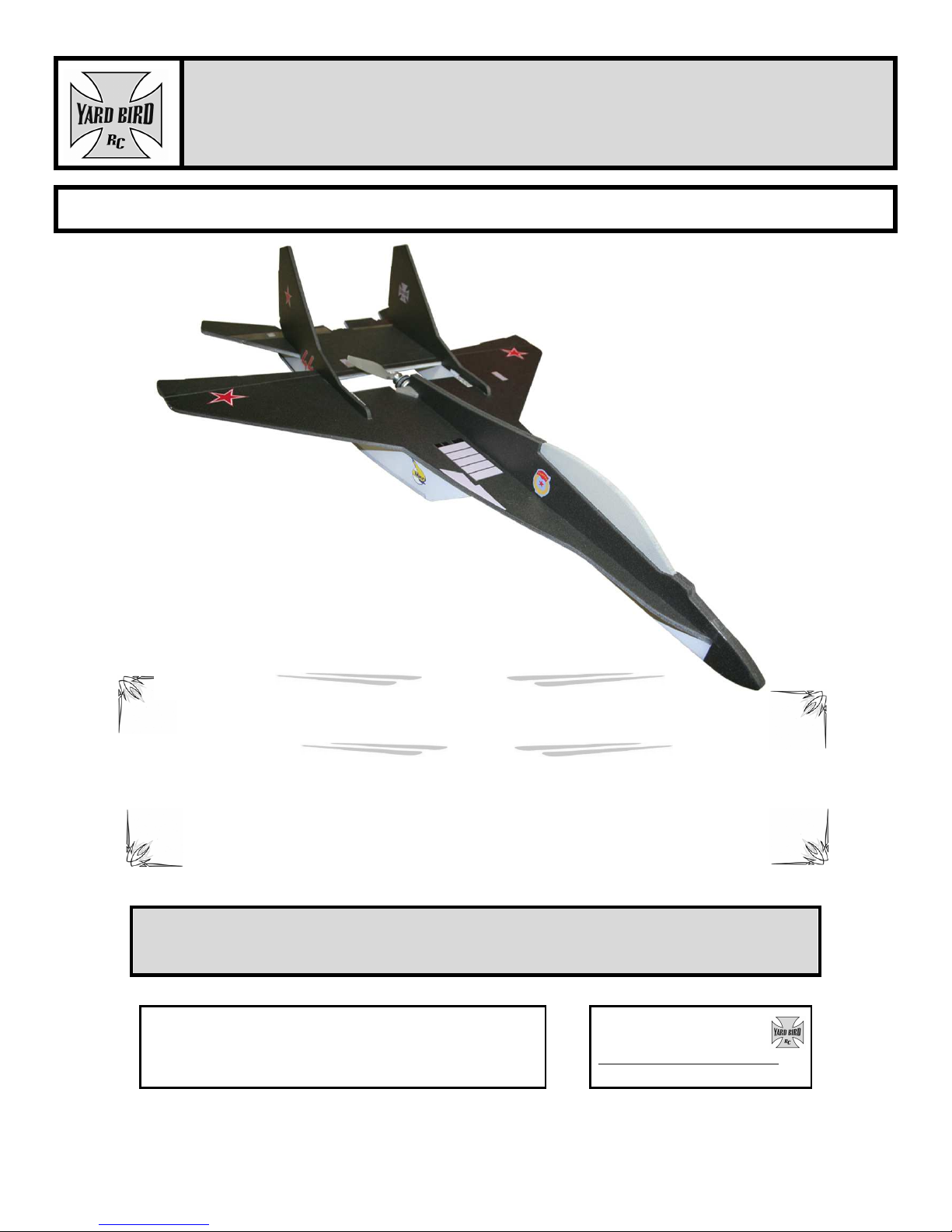

Thank you for your purchase of the Yardbird RC

Mig-29 Park Jet. It is our sincere hope that this product

will bring you many hours of fun and safe enjoyment.

This kit is primarily designed as a park flyer and has

been tested in light winds up to MPH. Please look for

the Yardbird RC YB-22 to complete the ultimate dog

fighting experience. Yardbird RC is proud of this kit

and we know that you will be happy with the quality

found inside the box. This kit was proudly

manufactured in the USA.

Yardbird RC

Safety First

This product is intended for use as a RC aircraft

for intermediate to advanced pilots. It should not be

used or thought of as a Toy. This product is capable

of speeds in excess of 0 MPH, and just like real

aircraft this model could cause damage to people or

property. Do not operate this kit in the vicinity of real

aircraft or groups of people. This model has a mid-

mounted propeller. This design feature is safer then a

nose or tail mounted prop. However special care should

be used around the propeller. Propellers can cause

damage and injuries. Please check local laws,

restrictions and park rules in your area in regards to

operating RC aircraft. Joining a local RC aircraft club

is a great idea. Your local hobby shop will have

information on local RC clubs. If you are not

experience with this type of RC model seek out the

help of an experienced RC pilot or instructor for your

first few flights.

Please take your time in building your kit. Follow the

directions in this manual. You must build this kit strong

and true. Do not alter or modify this kit, it will change

the flight characteristics in ways that may not be

predictable. Yardbird RC has worked diligently to

provide a quality kit. However the final assembly

and airworthiness of this kit will depend on how you

build it. Because Yardbird RC has no control over the

final assembly of this kit we don’t guarantee the flight

characteristics safety or airworthiness of this kit.

Pg. 2

Pg. 2

Pg. 2

Pg. 2

Pg. 2

Pg. 3

Pg. 4

Pg. 7

Pg. 9

Pg.10

Pg.10

Pg.11

Pg.11

Building Instructions

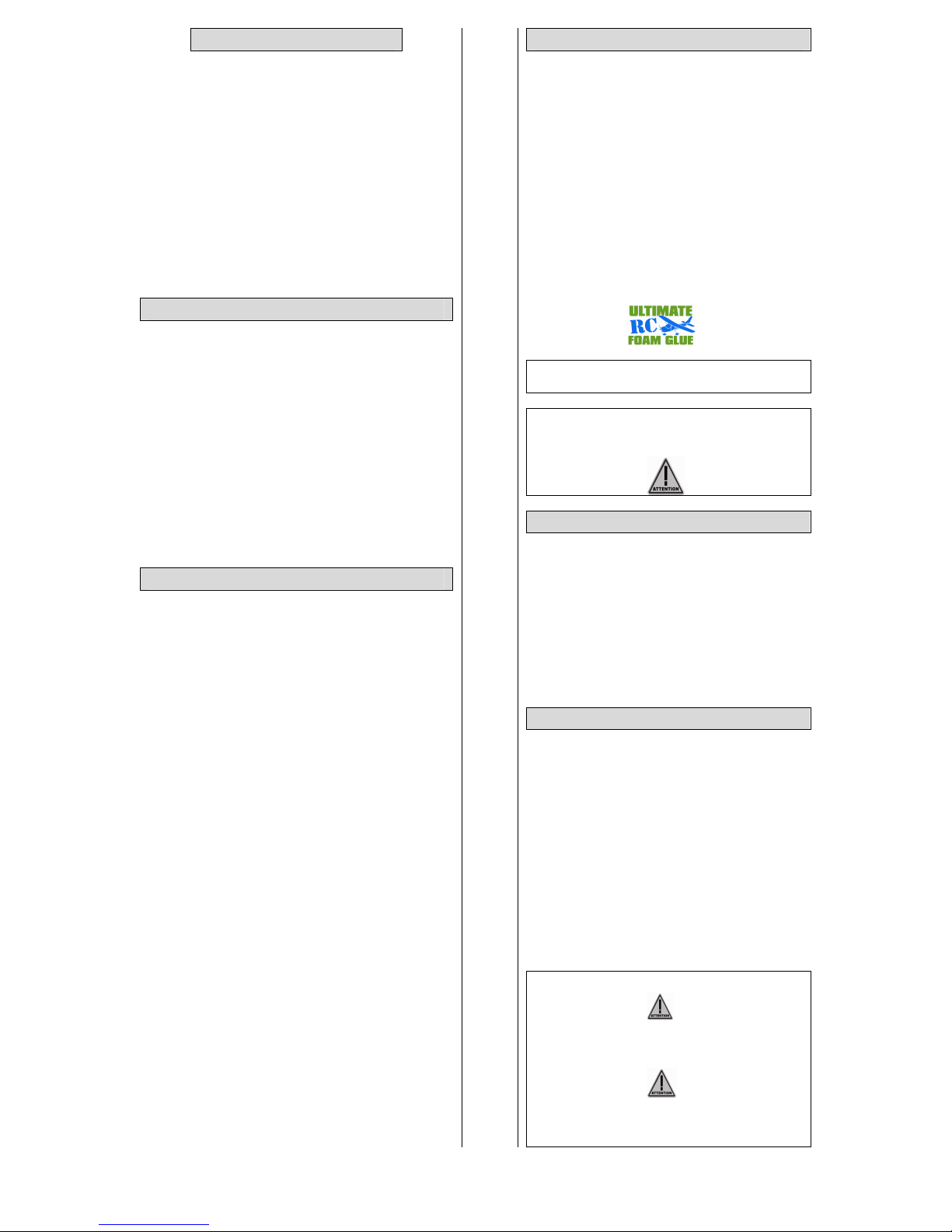

Each step is numbered so follow the order; don’t

skip ahead. The picture or pictures for each step is

placed before the written instructions. You should

look at the picture and read the instructions

thoroughly before completing each step.

Glue: Read the instruction for the glue you decide

to use with this kit. Use only foam safe glue. Use the

test piece of foam to test the glue before using it on

the rest of the kit. Remember glue adds weight. Too

little glue and the joint will be weak; too much the

aircraft will lose performance or not fly at all. We

recommend that you use Yardbird RC Ultimate RC

Foam Glue for the best results.

Test Fit:

Means to assemble the pieces without

glue.

Attention triangle: When you see this symbol

pay attention to the important instructions or

notes.

Additional Building Materials

- Foam glue: Yardbird RC Ultimate RC Foam Glue.

- CA glue: (Cyanoacrylate Glue) or Super Glue.

Only used for one step. A small bottle or tube

will work.

- X-ACTO knife with number 11 blade.

- 1. MM hex head wrench.

- Small cross point screw driver.

- Painters tape. Optional.

- Foam Safe Paint. Optional.

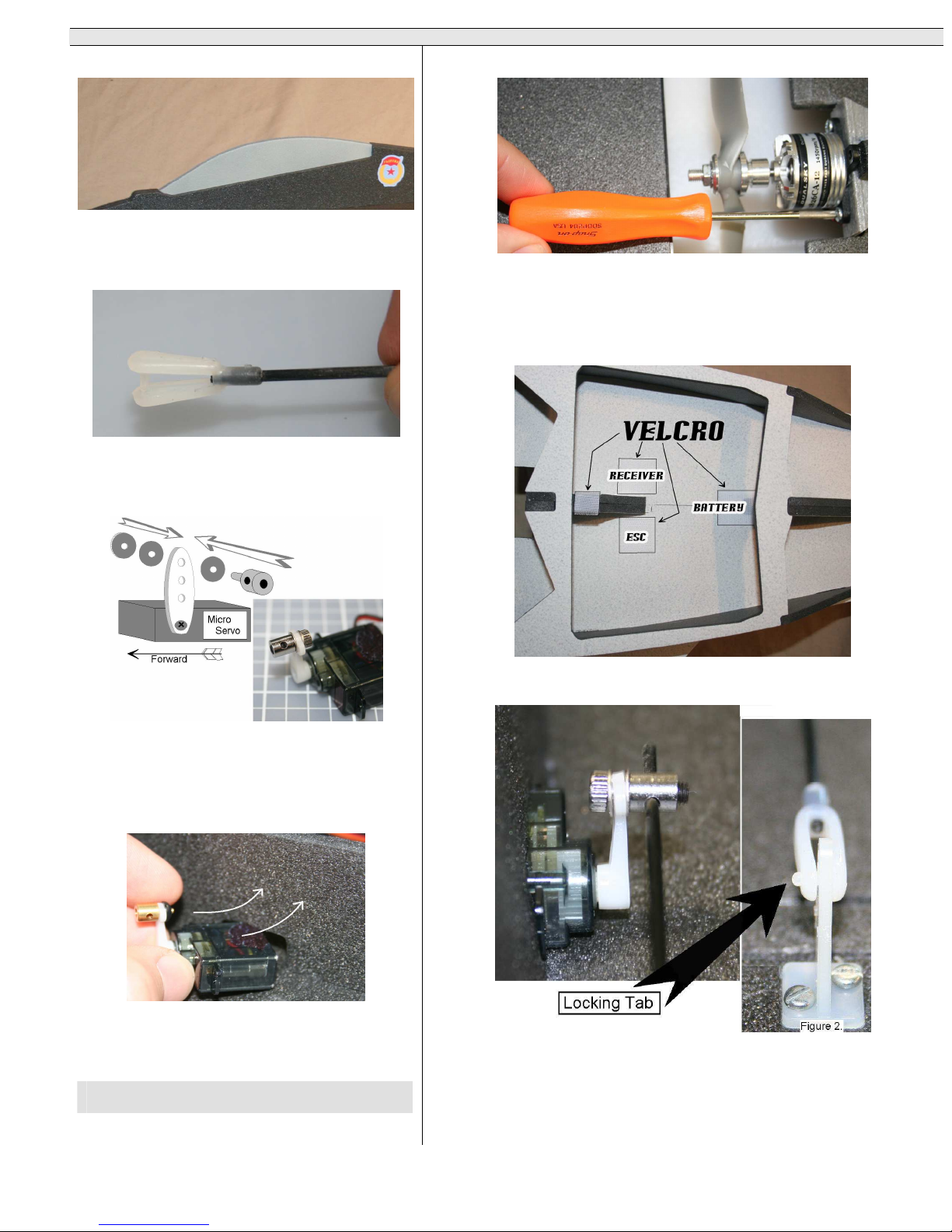

Recommended Electronics

Motor: DUALSKY XM2826CA-12

Brushless Outrunner.

Prop: ACP 7X .

Electronic Speed Control: DUALSKY XC1812BA.

attery: DUALSKY XP13003GT.

Radio Controller: This kit requires three channels

and v-tail mixing. A 2.4 GHz radio is

recommended for park flyers. Due to the reduced

risk of radio interference.

Please read all warning and setup information

enclosed in products to be used in combination

with this kit.

LITHIUM POLYMER ATTERYS

Can catch fire or explode. Always use and

maintain the manufacture recommendations!