BACnet Node Addressing

The BACnet node address is configurable by parameter F6-

45 in the drive. This defines the physical address of the drive

on the MS/TP network. In addition, both the Device Object

Instance Identifier (parameters F6-48 and F6-49) and the

Device Object Name are configurable. These allow the drive

to have a virtual address and simplify the controller

configuration.

After setting the addressing, a controller can initiate

communication to the drive. The drive will perform the

specified function and then send a response back to the

controller. The drive will usually respond immediately, but

may delay its response until it gets the token for commands

that may take extra local processing time.

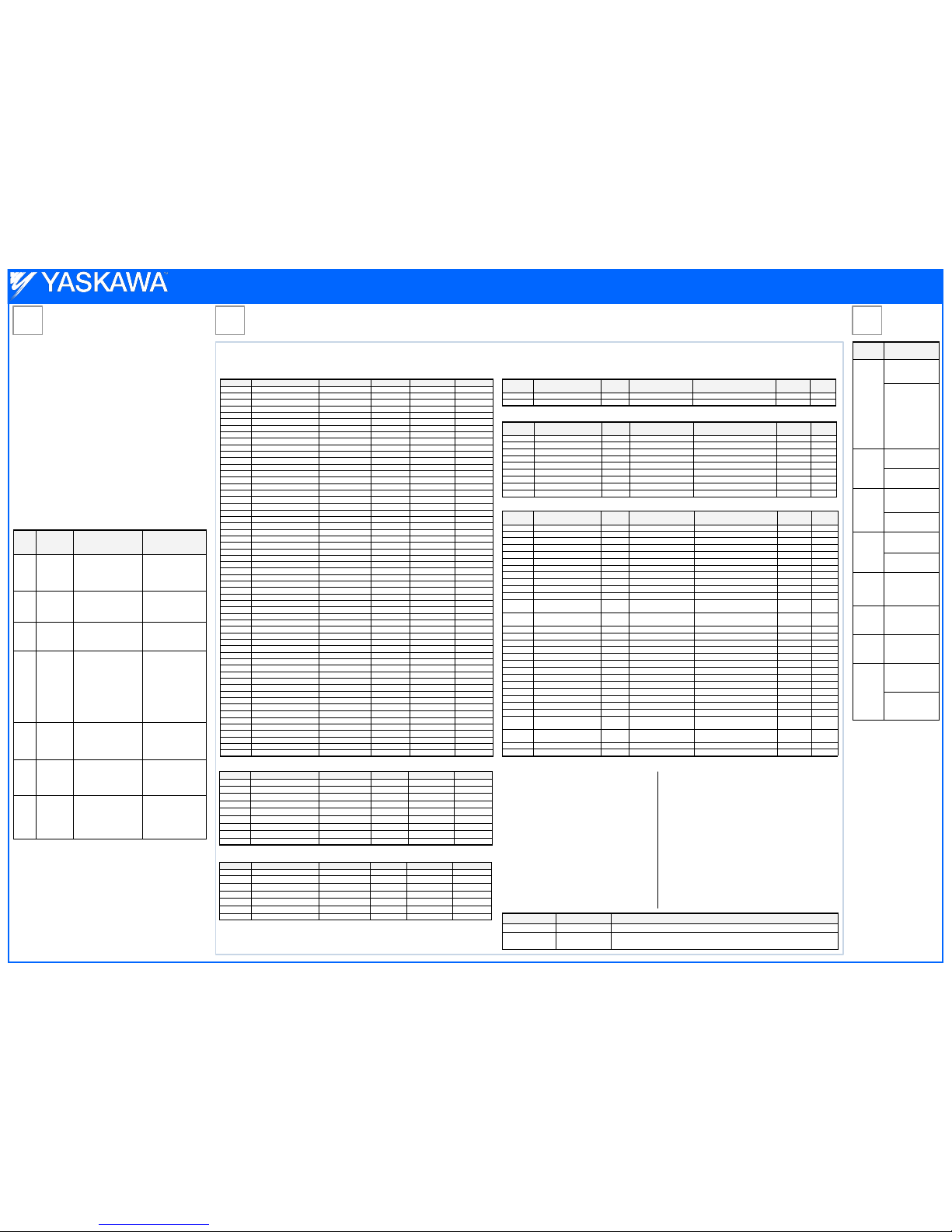

Related Drive Parameters

The following parameters are used to set up the drive for

operation with the option. Parameter setting instructions can

be found in the drive Quick Start Guide or Technical Manual.

Confirm proper setting of the all parameters in the table

below, before starting network communications. After

changing parameter settings, cycle power to the drive for the

new settings to take effect.

<1> To start and stop the drive with the option master device using

serial communications, set b1-02 to 3. To control the drive frequency

reference via the master device, set b1-01 to 3.

<2> These parameters set the Instance Identifier of the BACnet

Device Object, where the F6-48 value is the least significant word

and the F6-49 value is the most significant word.

Example 1: Set the Device Object Instance Identifier of "1234". 1234

decimal is equal to 4D2H (hexadecimal). Set F6-48 to 4D2H and

F6-49 to 0.

Example 2: Set Device Object Instance Identifier to "1234567".

1234567 decimal is equal to 12D687H. Set

F6-48 to D687H and set F6-49 to 12H.

`

Present Value Access

The Present Value (PV) of BACnet objects can be read. In addition, some PVs can be written or commanded. A commandable PV is similar to writing the value, but the value is actually written into a priority array. The value occupying the highest priority in

the array will be used by the drive. The convention for showing how the PV is accessed is C = Commandable, Value written to a priority array. R = Readable, Value is read-only, W = Writable, Value written to the drive.

Binary Value Objects Analog Outputs Objects

Binary Input Objects

Binary Output Objects

Analog Inputs Objects

Analog Value Objects

Reading Drive Parameters

Reading drive parameters not listed in the analog or digital objects is

accomplished using

AV29 and AV30 as shown below:

1. In decimal, write the desired Modbus register to AV29.

2. In decimal, read the value at the given register from AV30.

For example, to read the Frequency Reference Upper Limit, read

from parameter d2-01. Parameter d2-01 is located at Modbus register

0289H, which is decimal 649.

Set AV29 to “649”

Read AV30 to get the value.

Enter Command

Enter Commands are only required when using AV29 and AV30 to

write drive parameters. An Enter command is not required when

reading or writing to the other BACnet objects.

When writing parameters to the drive from a controller using BACnet

communications, an Enter command must be issued to enable these

parameters. This section describes the types and functions of the

Enter commands.

Accessing Drive Parameters

Writing Drive Parameters

Writing drive parameters not listed in the analog or digital objects is

accomplished using

AV29, AV30, and BV55 or BV56 as shown below:

1. In decimal, write the desired Modbus register to AV29.

2. In decimal, write the value to be written into AV30.

3. At this point the value is pending. One of two actions must be taken to

complete the writing process:

Set BV55 to “ON” to move data to active memory.

Set BV56 to “ON” to move data into active memory and save to non-volatile memory.

For example, to reset the KWH Monitor, write a value of “1” to parameter o1-12.

Parameter o1-12 is located at Modbus register 0512H, which is decimal 1298.

Set AV29 to “1298”

Set AV30 to “1”

Set BV55 to “ON”.

Enter Command Types

The drive supports two types of Enter commands as shown in the table below.

Object ID Object Name Modbus

Adress Precision Range Units PV

Access

AI1 Analog Input 1 Level 004EH XXXX.X –%R

AI2 Analog Input 2 Level 004FH XXXX.X –%R

AI3 Not Used AI3 –––––

AI4 Not Used AI4 –––––

AI5 Not Used AI5 –––––

AI6 Display Format o1-03 0502H XXXXX ––R

AI7 Scale Format b5-20 01E2H XXXXX ––R

AI8 Inverter Model o2-04 0508F XXXXX ––R

AI9 Rated Current n9-01 05D0H XXXX.X –Amps R

Object ID Object Name Modbus

Adress Precision Range Units PV

Acess

AO1 Analog Output 1 Level 0007H XXXX.X 0 to 100.0 %C

AO2 Analog Output 2 Level 0008H XXXX.X 0 to 100.0 %C

Object ID Object Name Modbus

Adress Precision Range Units PV

Access

AV1 Operation Cmd 0001H XXXXX 0 to 65535 –C

AV2 Frequency Cmd 0002H XXX.XX Dep. on o1-03 0.00 to 600.00 Hz (o1-03) C

AV3 PI Setpoint Cmd 0006H XXX.XX 0.00 to 100.00 %C

AV4 MF Output 1 Cmd 0009H XXXXX 0 to 65535 –C

AV5 Reference Select Cmd 000FH XXXXX ––C

AV6 Drive Status 0020H XXXXX ––R

AV7 Fault Details 0021H XXXXX ––R

AV8 Data Link Status 0022H XXXXX ––R

AV9 Frequency Reference 0040H XXX.XX Dep. on o1-03 –Hz (o1-03) R

AV10 Output Frequency 0041H XXX.XX Dep. on o1-03 –Hz (o1-03) R

AV11 Output Voltage 0045H XXXX.X –Volts R

AV12 Output Current 0042H XXXX.X (>11 kVA)

XXX.XX (<=11 kVA) –Amps R

AV13 Output Power 0047H XXXX.X (>11 kVA)

XXX.XX (<=11 kVA) –Watts R

AV14 Torque Reference 0048H XXXX.X –%R

AV15 MF Input Status 002BH XXXXX ––R

AV16 Drive Status 2 002CH XXXXX ––R

AV17 MF Output Status 002DH XXXXX ––R

AV18 DC Bus Voltage 0031H XXXX.X –Volts R

AV19 PI Feedback Level 0038H XXXX.X –%R

AV20 PI Input Level 0039H XXXX.X –%R

AV21 PI Output Level 003AH XXXX.X –%R

AV22 CPU Software 005BH XXXXX ––R

AV23 Flash Number 004DH XXXXX ––R

AV24 Comm Error Detail 003DH XXXXX ––R

AV25 kVA Setting 0508H XXXXX ––R

AV26 Control Method 0102H XXXXX ––R

AV27 Accel Time 0200H XXXX.X (C1-10 = 1)

XXX.XX (C1-10 = 0)

0.0 to 6000.0 (C1-10=1)

0.00 to 600.00 (C1-10 = 0) Sec W

AV28 Decel Time 0201H XXXX.X (C1-10 = 1)

XXX.XX (C1-10 = 0)

0.0 to 6000.0 (C1-10=1)

0.00 to 600.00 (C1-10 = 0) Sec W

AV29 Parameter Number –XXXXX 0 to FFFFH –W

AV30 Parameter Data –XXXXX 0 to FFFFH –W

Object ID Object Name Modbus Address Active Text Inactive Text PV Access

BI1 Input Terminal 1 002BH:bit 0 ON OFF R

BI2 Input Terminal 2 002BH:bit 1 ON OFF R

BI3 Input Terminal 3 002BH:bit 2 ON OFF R

BI4 Input Terminal 4 002BH:bit 3 ON OFF R

BI5 Input Terminal 5 002BH:bit 4 ON OFF R

BI6 Input Terminal 6 002BH:bit 5 ON OFF R

BI7 Input Terminal 7 002BH:bit 6 ON OFF R

BI8 Multi-Function Out 1 0020H:bit 5 ON OFF R

BI9 Multi-Function Out 2 0020H:bit 6 ON OFF R

Object ID Object Name Modbus Address Active Text Inactive Text PV Access

BO1 MF Output M1-M2 0009H:bit 0 ON OFF C

BO2 MF Output M3-M4 0009H:bit 1 ON OFF C

BO3 MF Output M5-M6 0009H:bit 2 ON OFF C

BO4 Ref Sel:PI Setpoint 000FH:bit 1 ON OFF C

BO5 Ref Sel:Term S5 IN 0001H:bit 8 ON OFF C

BO6 Ref Sel:Term S6 IN 0001H:bit 9 ON OFF C

BO7 Refl Sel:Term S7 IN 0001H:bit 10 ON OFF C

Object ID Object Name Modbus Address Active Text Inactive Text PV Access

BV1 Run FWD Cmd 0001H:bit 0 RUN OFF C

BV2 Run REV Cmd 0001H:bit 1 REV OFF C

BV3 Ext Fault Cmd 0001H:bit 2 FAULT OFF C

BV4 Fault Reset Cmd 0001H:bit 3 RESET OFF C

BV5 Com Net Cmd 0001H:bit 4 COM LOCAL C

BV6 Com Cntrl Cmd 0001H:bit 5 COM LOCAL C

BV7 MF Input 3 Cmd 0001H:bit 6 ON OFF C

BV8 MF Input 4 Cmd 0001H:bit 7 ON OFF C

BV9 MF Input 5 Cmd 0001H:bit 8 ON OFF C

BV10 MF Input 6 Cmd 0001H:bit 9 ON OFF C

BV11 MF Input 7 Cmd 0001H:bit 10 ON OFF C

BV12 Set Fault Contact Cmd 0009H:bit 6 ENABLE OFF C

BV13 RUN-STOP 0020H:bit 0 RUN OFF R

BV14 REV-FWD 0020H:bit 1 REV FWD R

BV15 READY 0020H:bit 2 READY OFF R

BV16 FAULT 0020H:bit 3 FAULTED OFF R

BV17 Data Set Error 0020H:bit 4 ERROR OFF R

BV18 Overcurrent – Gnd Fault 0021H:bit 0 OC-GF OFF R

BV19 Main Ckt Overvoltage 0021H:bit 1 OV OFF R

BV20 Drive Overload 0021H:bit 2 OL2 OFF R

BV21 Drive Overheat 0021H:bit 3 OH1-OH2 OFF R

BV22 Fuse Blown 0021H:bit 5 PUF OFF R

BV23 PI Feedback Loss 0021H:bit 6 FBL OFF R

BV24 External Fault 0021H:bit 7 EF0-EF OFF R

BV25 Hardware Error 0021H:bit 8 CPF OFF R

BV26 Mtr Ovrld-OvrTorque 0021H:bit 9 OL1-OL3 OFF R

BV27 Overspeed 0021H:bit 10 OS-DEV OFF R

BV28 Main Ckt Undervoltage 0021H:bit 11 UV OFF R

BV29 MCU, Cntl Pwr Sy Err 0021H:bit 12 UV1-2-3OFF R

BV30 Output Phase Loss 0021H:bit 13 LF OFF R

BV31 Communication Error 0021H:bit 14 CE OFF R

BV32 Operator Disconnect 0021H:bit 15 OPR OFF R

BV33 Operating 002CH:bit 0 OPERATING OFF R

BV34 Zero Speed 002CH:bit 1 ON OFF R

BV35 Frequency Agree 002CH:bit 2 ON OFF R

BV36 Desired Freq Agree 002CH:bit 3 ON OFF R

BV37 Frequency Detect 1 002CH:bit 4 ON OFF R

BV38 Frequency Detect 2 002CH:bit 5 ON OFF R

BV39 Drv Startup Complete 002CH:bit 6 ON OFF R

BV40 Low Voltage Detect 002CH:bit 7 ON OFF R

BV41 Base Block 002CH:bit 8 ON OFF R

BV42 Frequency Ref Mode 002CH:bit 9 COM LOCAL R

BV43 Run Command Mode 002CH:bit 10 COM LOCAL R

BV44 Overtorque Detect 002CH:bit 11 ON OFF R

BV45 Frequency Refer Lost 002CH:bit 12 ON OFF R

BV46 Retry Error 002CH:bit 13 ON OFF R

BV47 Modbus Comms Error 002CH:bit 14 ON OFF R

BV48 Modbus Timeout Error 002CH:bit 15 ON OFF R

BV49 CRC Error 003DH:bit 0 ON OFF R

BV50 Invalid Data Length 003DH:bit 1 ON OFF R

BV51 Parity Error 003DH:bit 3 ON OFF R

BV52 Overrun Error 003DH:bit 4 ON OFF R

BV53 Framing Error 003DH:bit 5 ON OFF R

BV54 Timeout Error 003DH:bit 6 ON OFF R

BV55 Parameter Accept 0910H:bit 0 ON OFF W

BV56 Parameter Enter 0900H:bit 0 ON OFF W

BV57 Drive Comms Error - ON OFF R

BACnet Object Modbus Address Description

BV55 (Write “ON”) 0910H (bit 0) Writes data in the active RAM only. Parameter changes are lost when the drive is shut off.

BV56 (Write “ON”) 0900H (bit 0) Simultaneously writes data into the EEPROM (non-volatile memory) of the drive and ena-

bles the data in active RAM. Parameter changes remain after cycling power.

Error

Codes