Yaskawa Solectria Solar DOCR-071070 Page 2of 30

Contents

1. IMPORTANT SAFETY INSTRUCTIONS............................................................................................... 3

Hazard Symbols ....................................................................................................................... 4

Symbols on Labels.................................................................................................................... 5

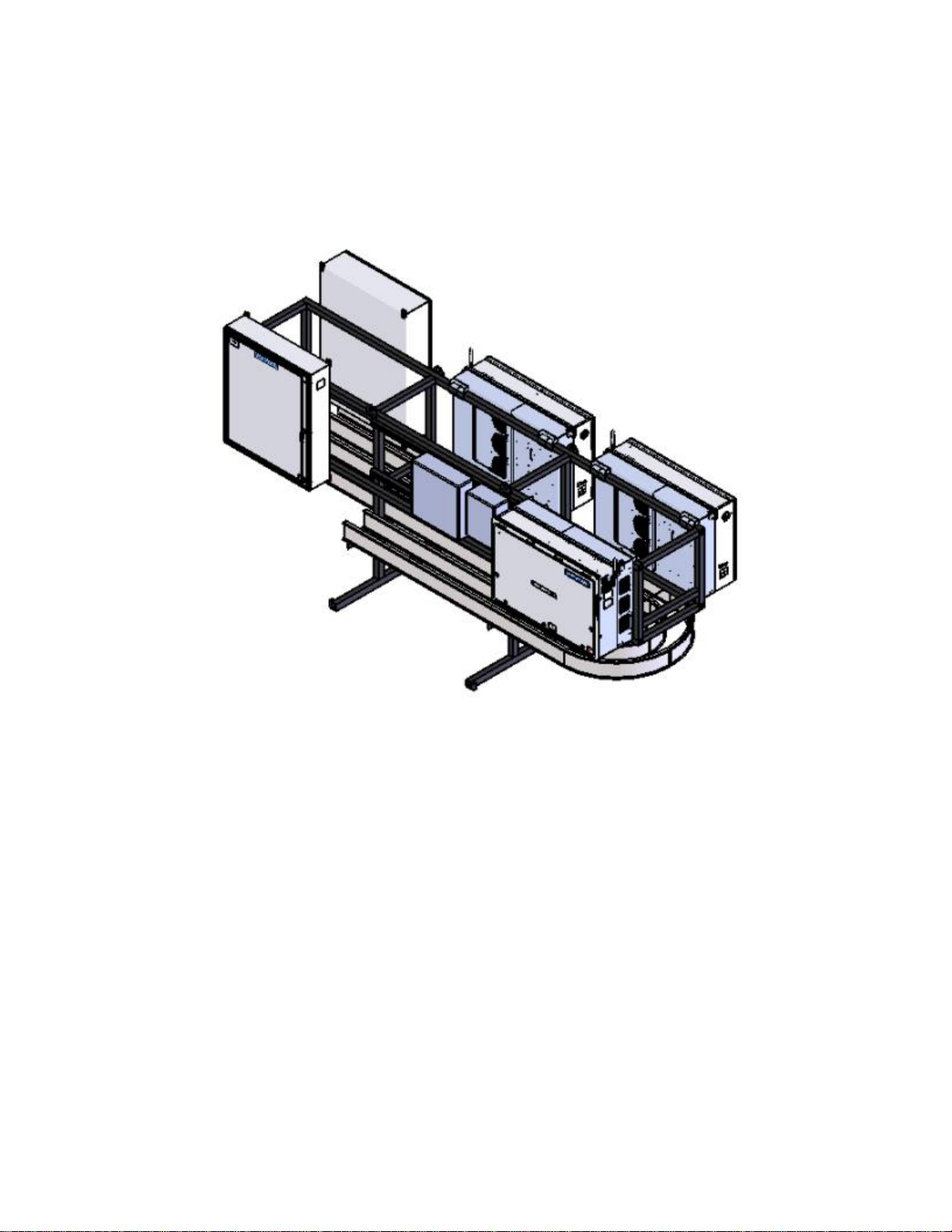

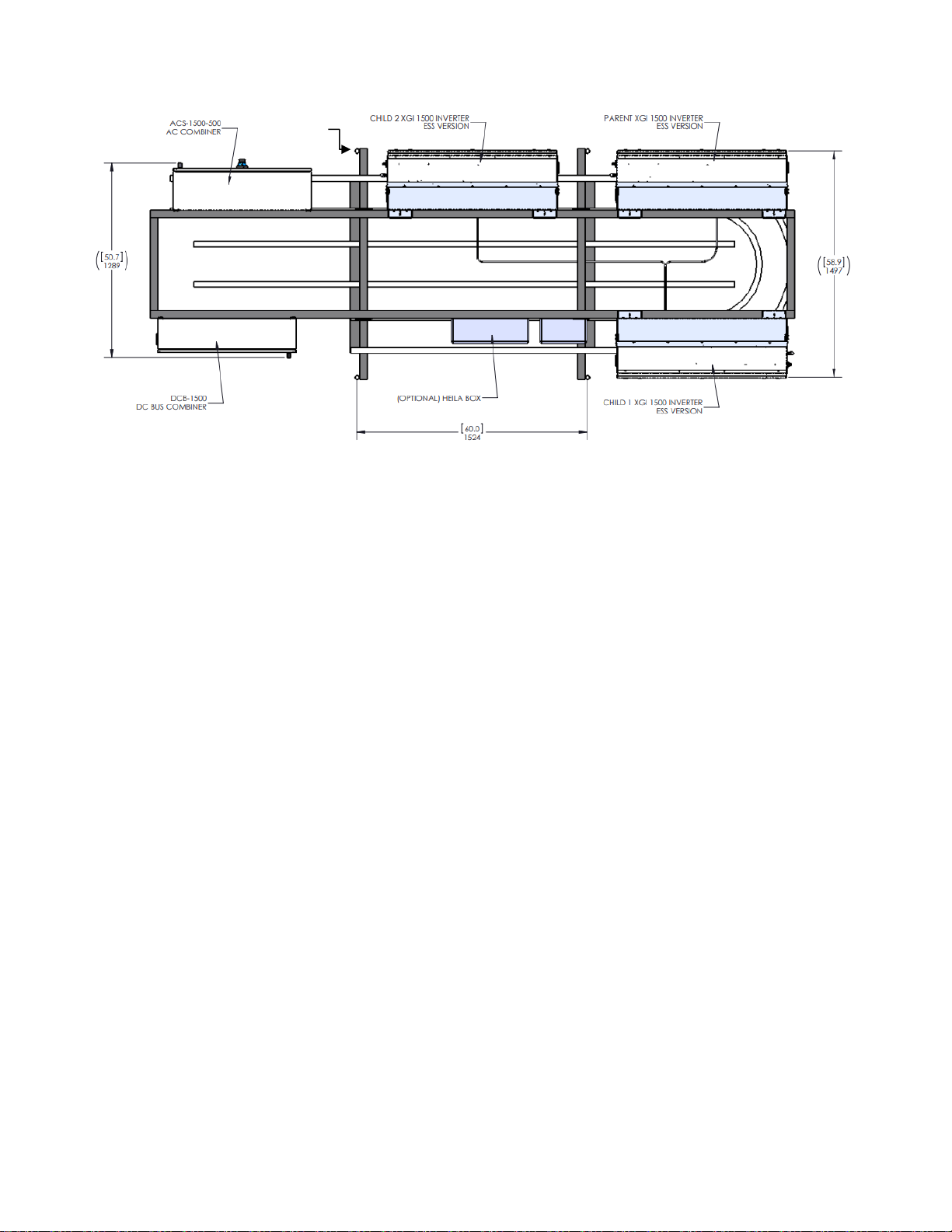

2. SYSTEM OVERVIEW......................................................................................................................... 6

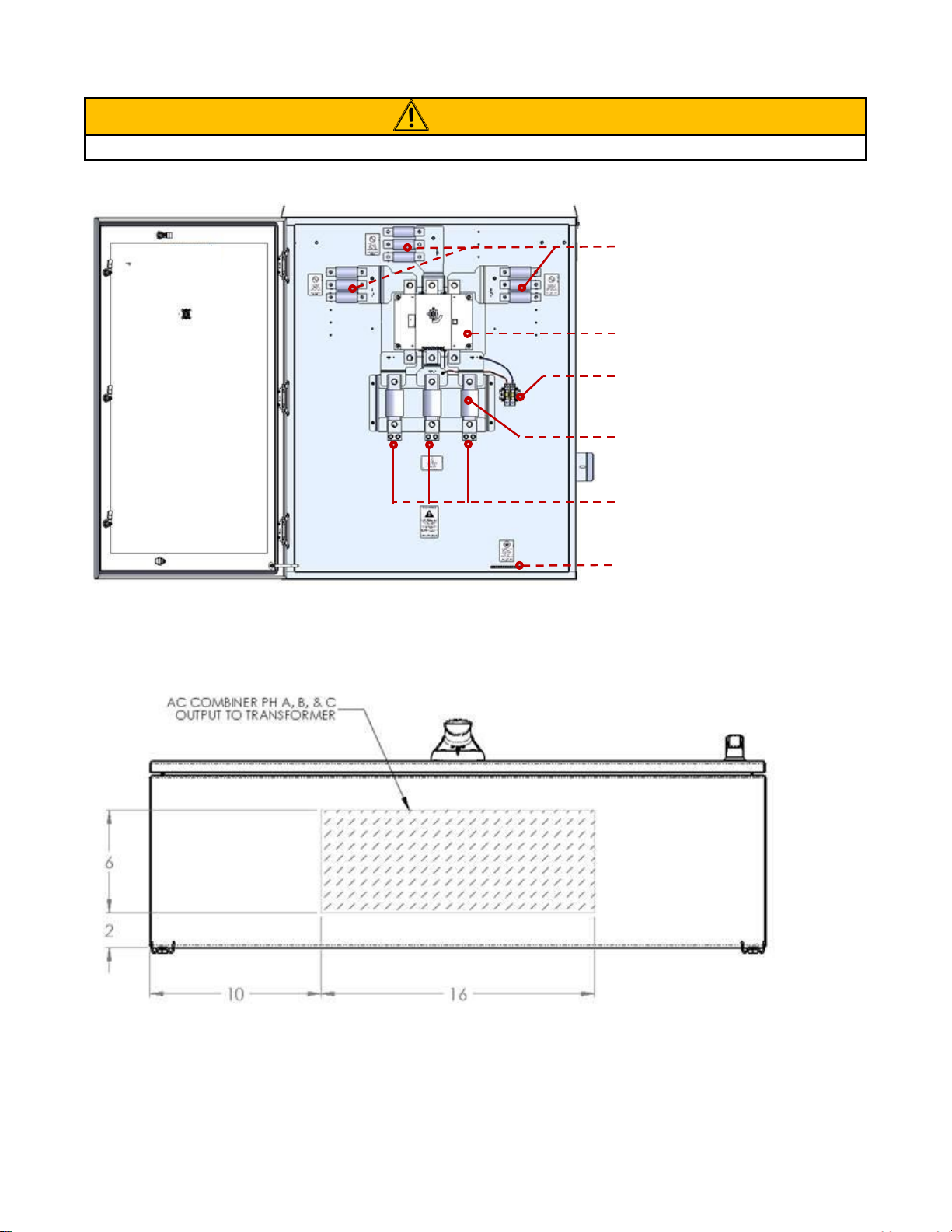

3. INSTALLATION................................................................................................................................. 8

Delivery ................................................................................................................................... 8

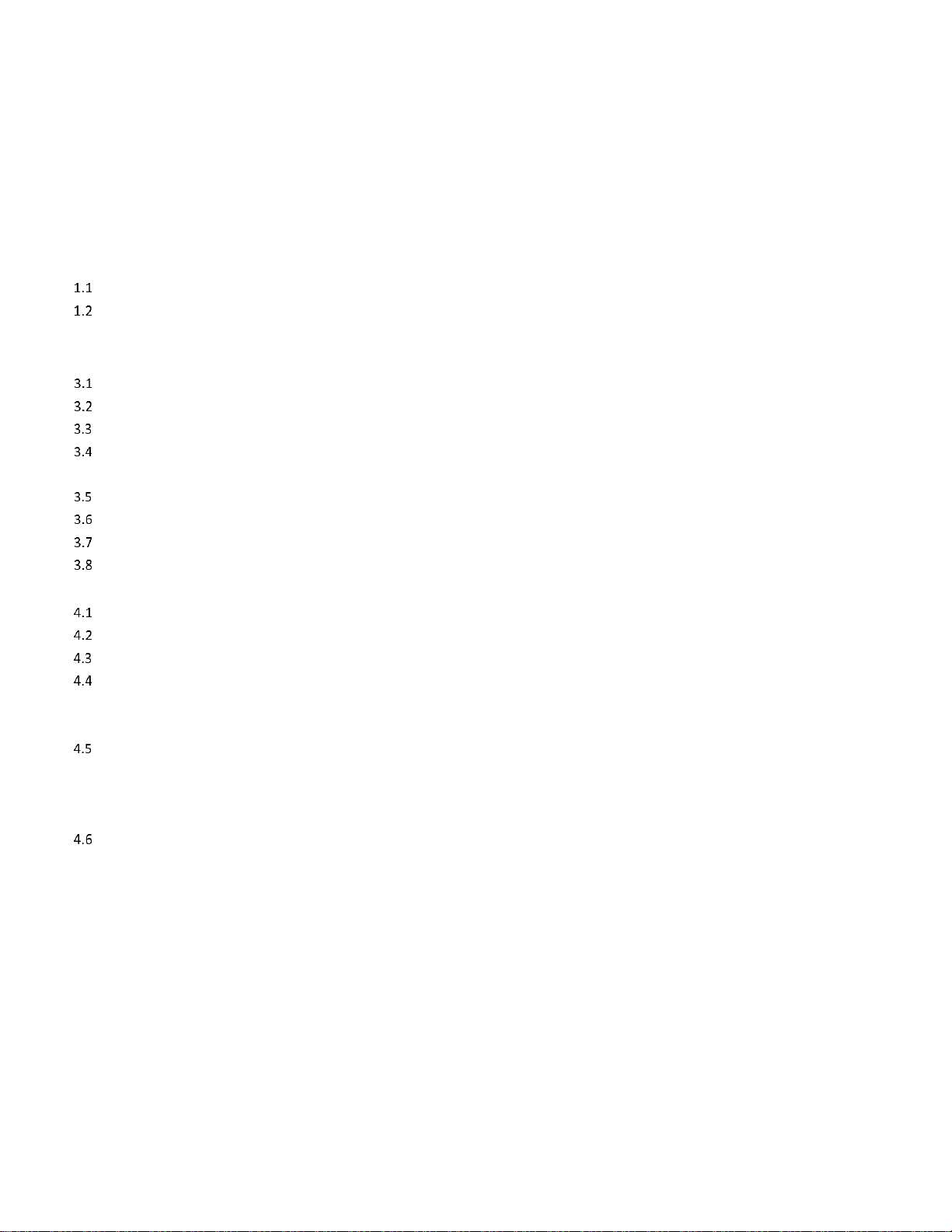

Placement and Anchoring........................................................................................................ 8

AC Wiring................................................................................................................................. 9

DC Wiring of the DC Bus De-Combiner................................................................................... 14

3.4.1 Fastening Lugs to the Studs ............................................................................................ 17

Precautions for Aluminum Wire............................................................................................. 19

Conduit Connections.............................................................................................................. 20

Heila PMC Communications (option) ..................................................................................... 21

Connection to the Internet .................................................................................................... 21

4. System Operation ......................................................................................................................... 22

Initial Commissioning Procedure............................................................................................ 22

System OFF Procedure........................................................................................................... 23

System ON Procedure............................................................................................................ 23

System Configuration............................................................................................................. 24

4.4.1 Defining the Maximum and the Minimum Battery Operational Voltage.......................... 24

4.4.2 Constant communication between PMC and inverters ................................................... 24

Control of Active Power......................................................................................................... 25

4.5.1 Active Power Limit.......................................................................................................... 25

4.5.2 Volt-Watt configuration.................................................................................................. 25

4.5.3 Frequency-Watt configuration........................................................................................ 26

Control of Reactive Power ..................................................................................................... 27

4.6.1 Method 1: Volt-VAr configuration................................................................................... 27

4.6.2 Method 2: Constant Power Factor Configuration............................................................ 28

4.6.3 Method 3: Constant Reactive Power configuration......................................................... 28

5. Specifications................................................................................................................................ 29

6. WARRANTY & RMA INSTRUCTIONS............................................................................................... 29

8. APPENDICES.................................................................................................................................. 30