YG125-30B Maintenance Manual Overview

2

MaintenancePrecautions

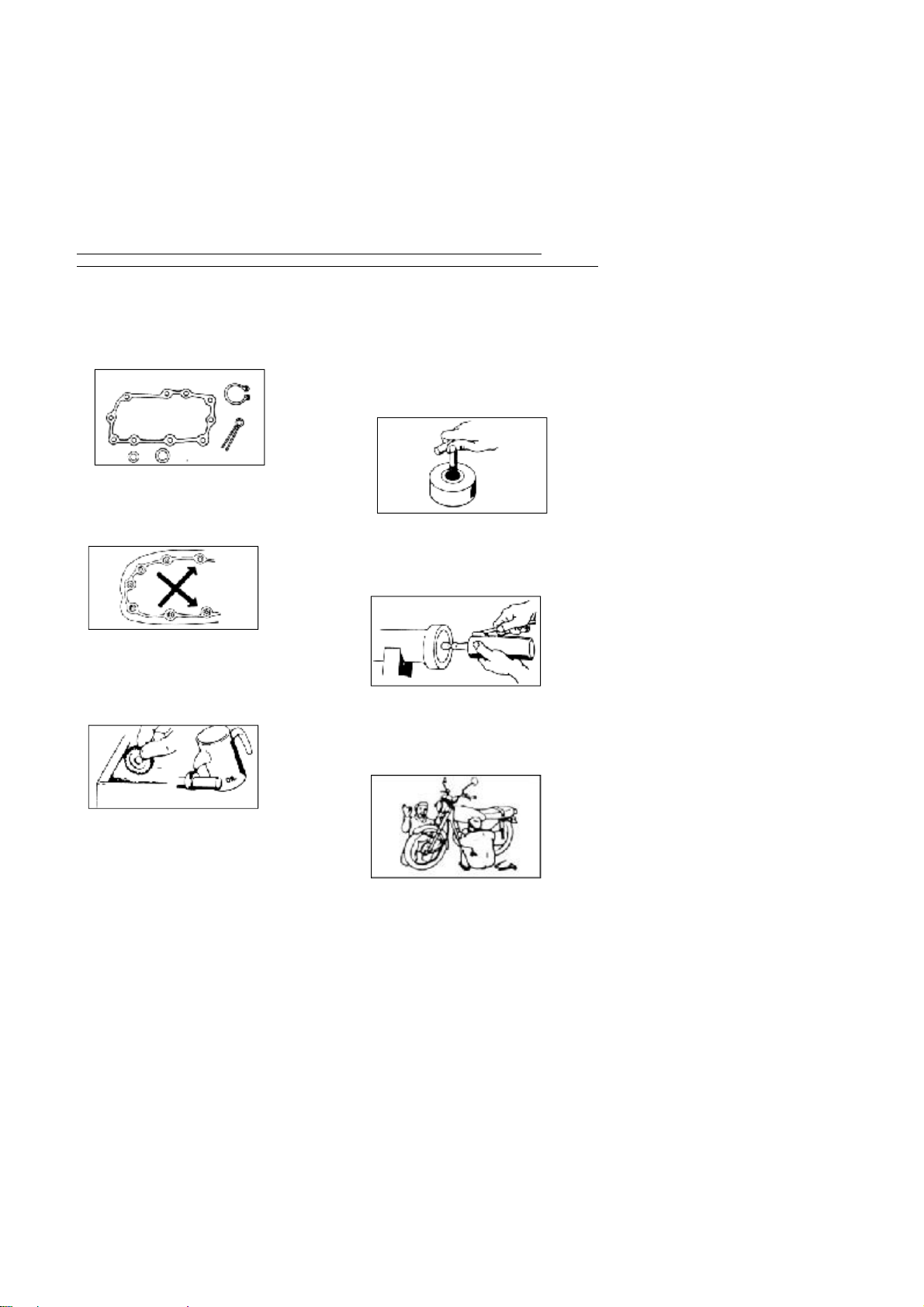

1. Wheneverreassemblingafterbeingdisassembled,

replacenewwashers,sealingmembers,etc.

2. Whilefasteningboltsornuts,proceedindiagonal

crossingsequencetograduallyscrewdowntothe

requiredtorquefor2to3tries.

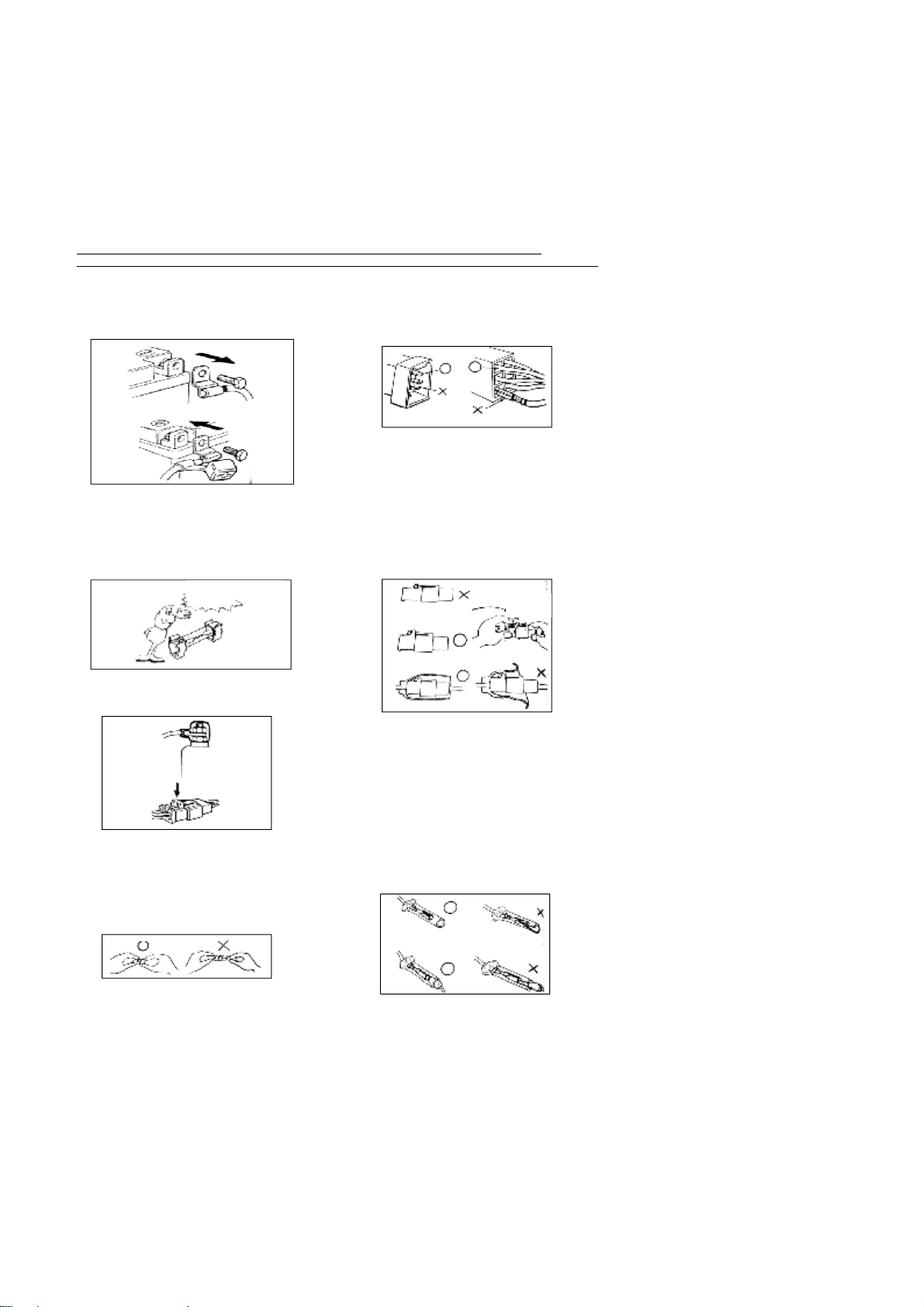

3. Afterbeingdisassembled,thepartsand

componentsshouldbecleanedbeforebeing

inspectedandmeasured

Tocleanthespareparts,useonlythecleaning

fluidthatisincombustibleorhashighignitionpoint.

Beforereassembling,applythespecified

lubricatingoiltotheslidingsurfaceofthepartsand

components.

Afterreassembling,checkwhetherallthespare

partsaremountedproperlybymeansofturning,

movingandoperatingthem.

4. Todisassembleandassembleamotorcycle,

specialservicetools(SST)andgeneral-purpose

toolsmustbeusedinaccordancewithrelevant

regulations.

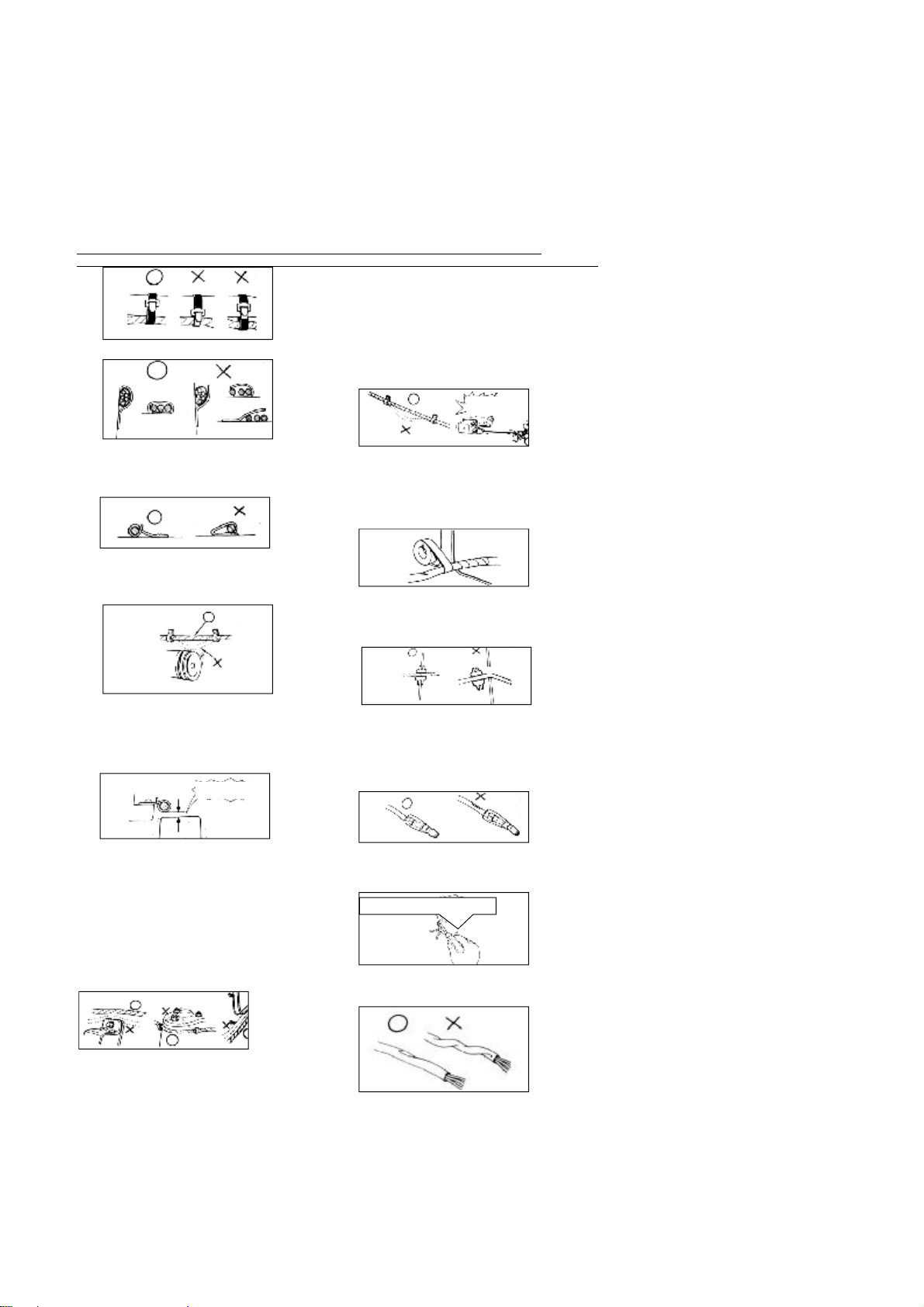

5. Thespecifiedorequivalentlubricatinggrease(oil)

mustbeappliedtoorrefilledintothespecified

locations.

6. When2ormorepersonsarecarryingoutthe

operation,theyshallworkwitheachotherandpay

attentiontosafety.

7. Beforeoperating,alwaysremovethenegative(-)

endofthebatteryfirstandtakecaretopreventthe

wrenchorthelikefromtouchingtheframe.After

operating,reconfirmalltheconnections,fixings

andjunctions.Ifthebatteryisalreadyremoved,

connectthepositive(+)endfirst.