YG48Q-5AMaintenanceManualOverview

Maintenance Precautions

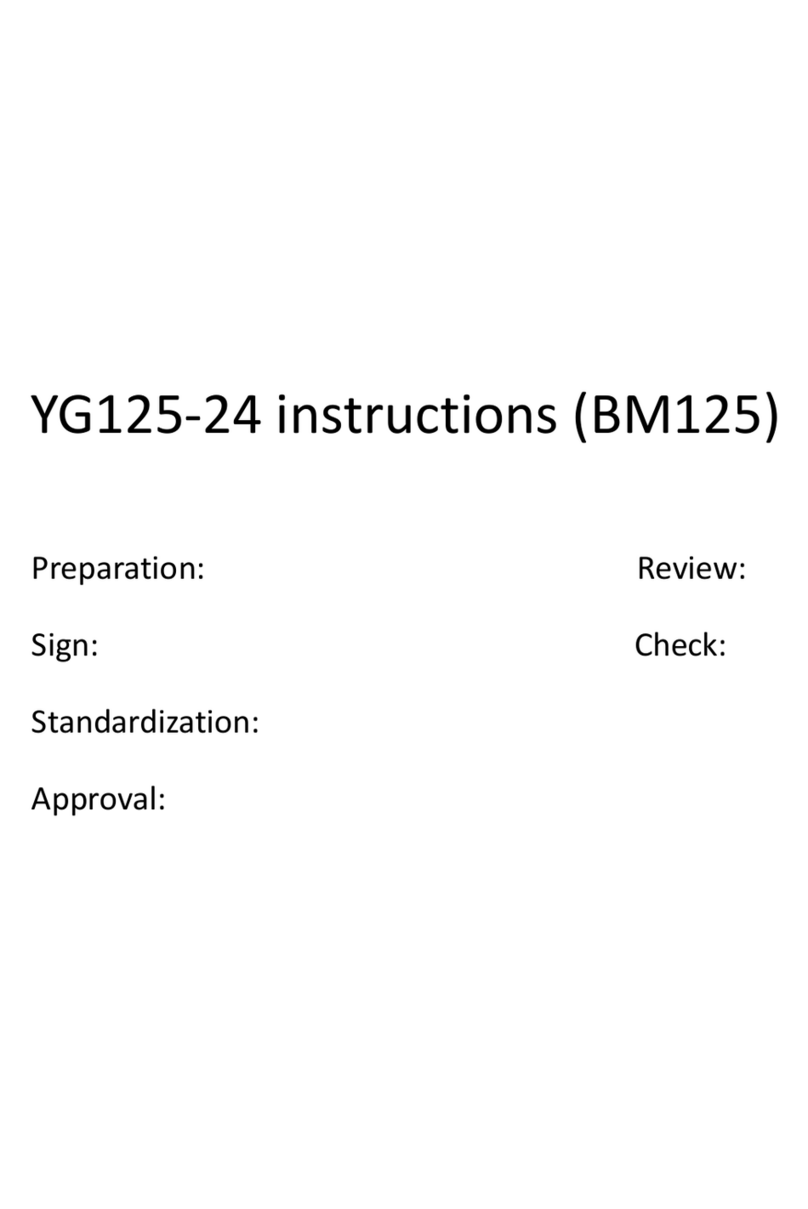

1. Whenever reassembling after being disassembled,

replace new washers, sealing members, etc.

2. While fastening bolts or nuts, proceed in diagonal

crossing sequence to gradually screw down to the

required torque for 2 to 3 tries.

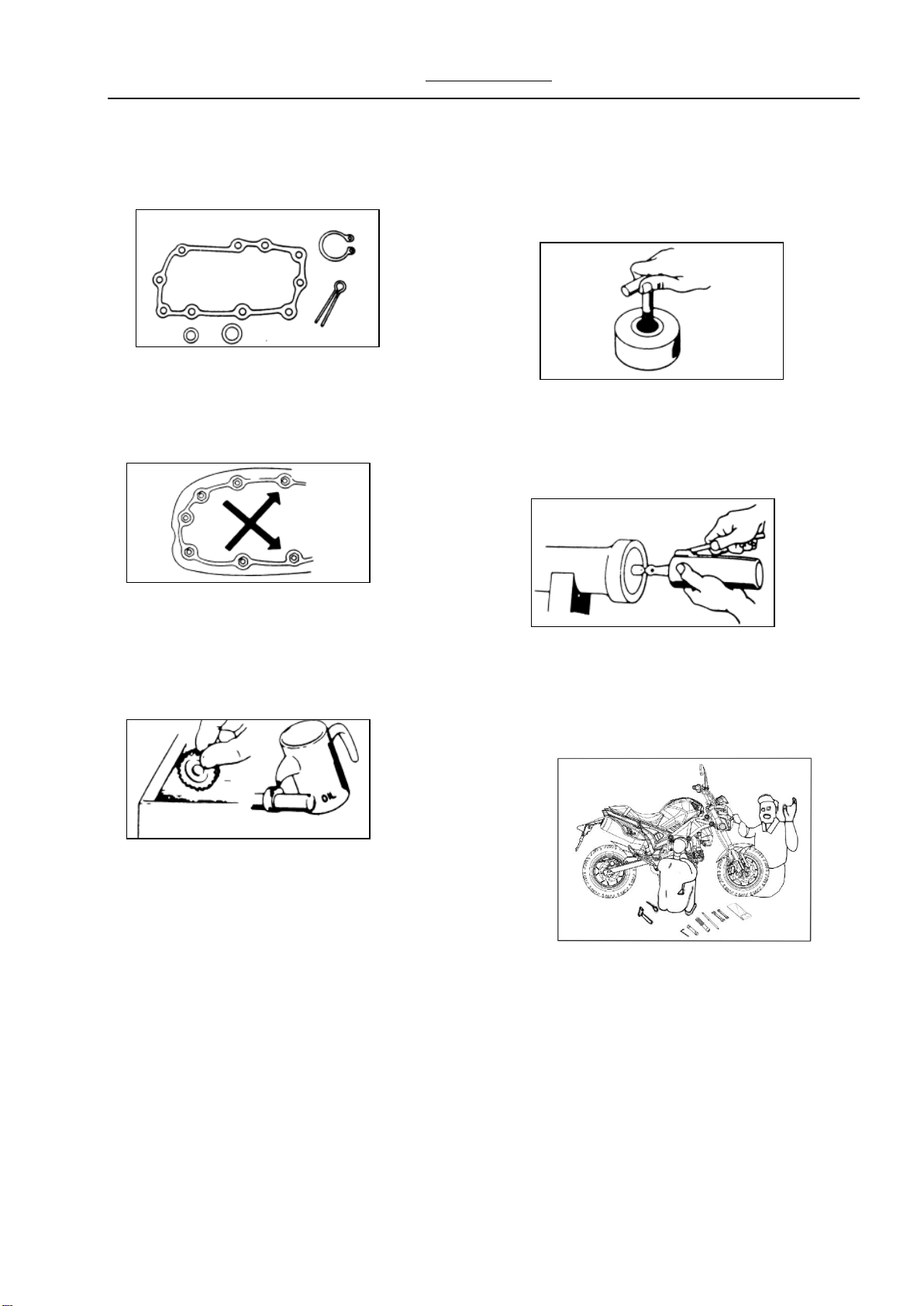

3. After being disassembled, the parts and

components should be cleaned before being

inspected and measured

To clean the spare parts, use only the cleaning

fluid that is incombustible or has high ignition point.

Before reassembling, apply the specified

lubricating oil to the sliding surface of the parts and

components.

After reassembling, check whether all the spare

parts are mounted properly by means of turning,

moving and operating them.

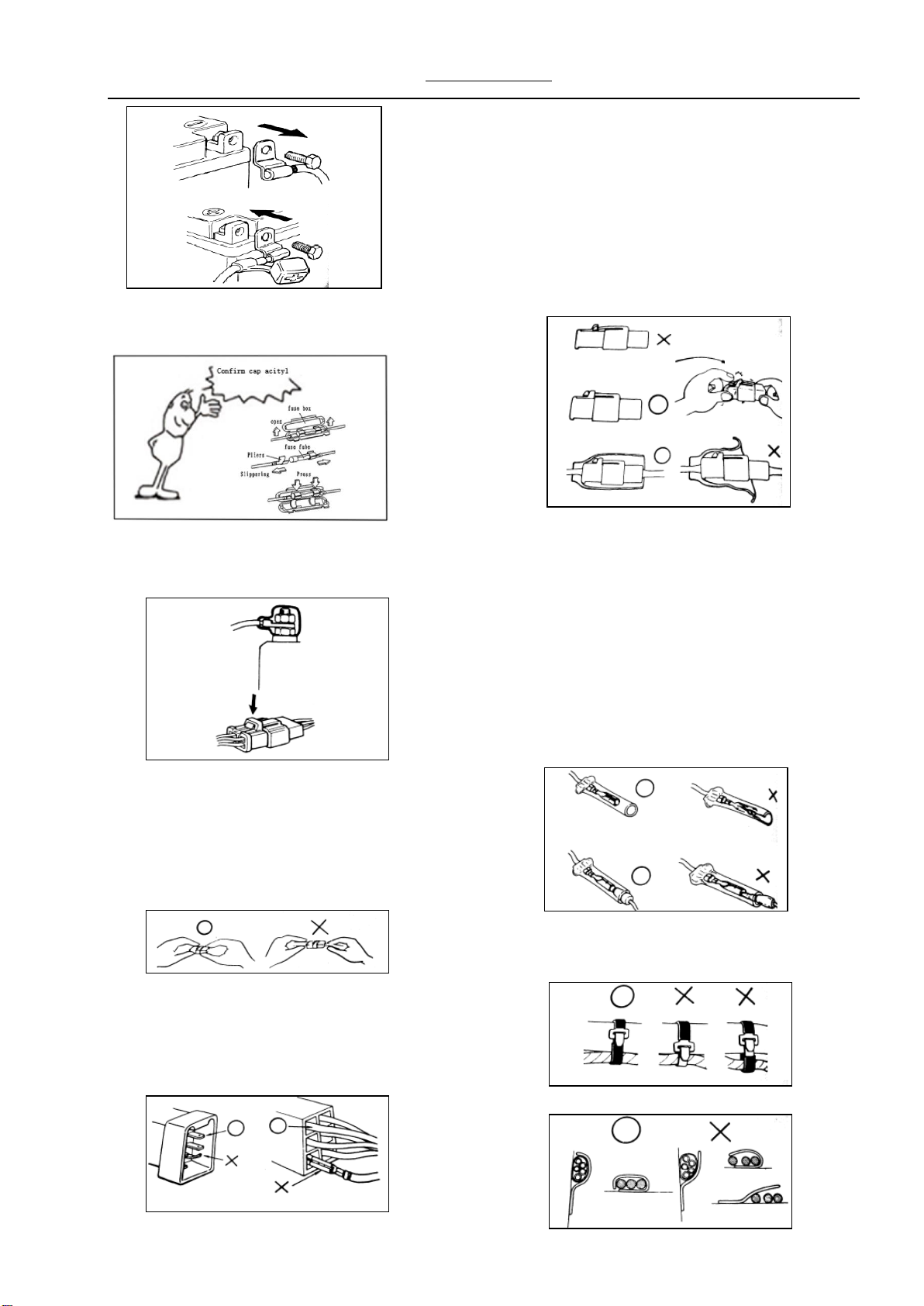

4. To disassemble and assemble a motorcycle,

special service tools (SST) and general-purpose

tools must be used in accordance with relevant

regulations.

5. The specified or equivalent lubricating grease (oil)

must be applied to or refilled into the specified

locations.

6. When 2 or more persons are carrying out the

operation, they shall work with each other and pay

attention to safety.

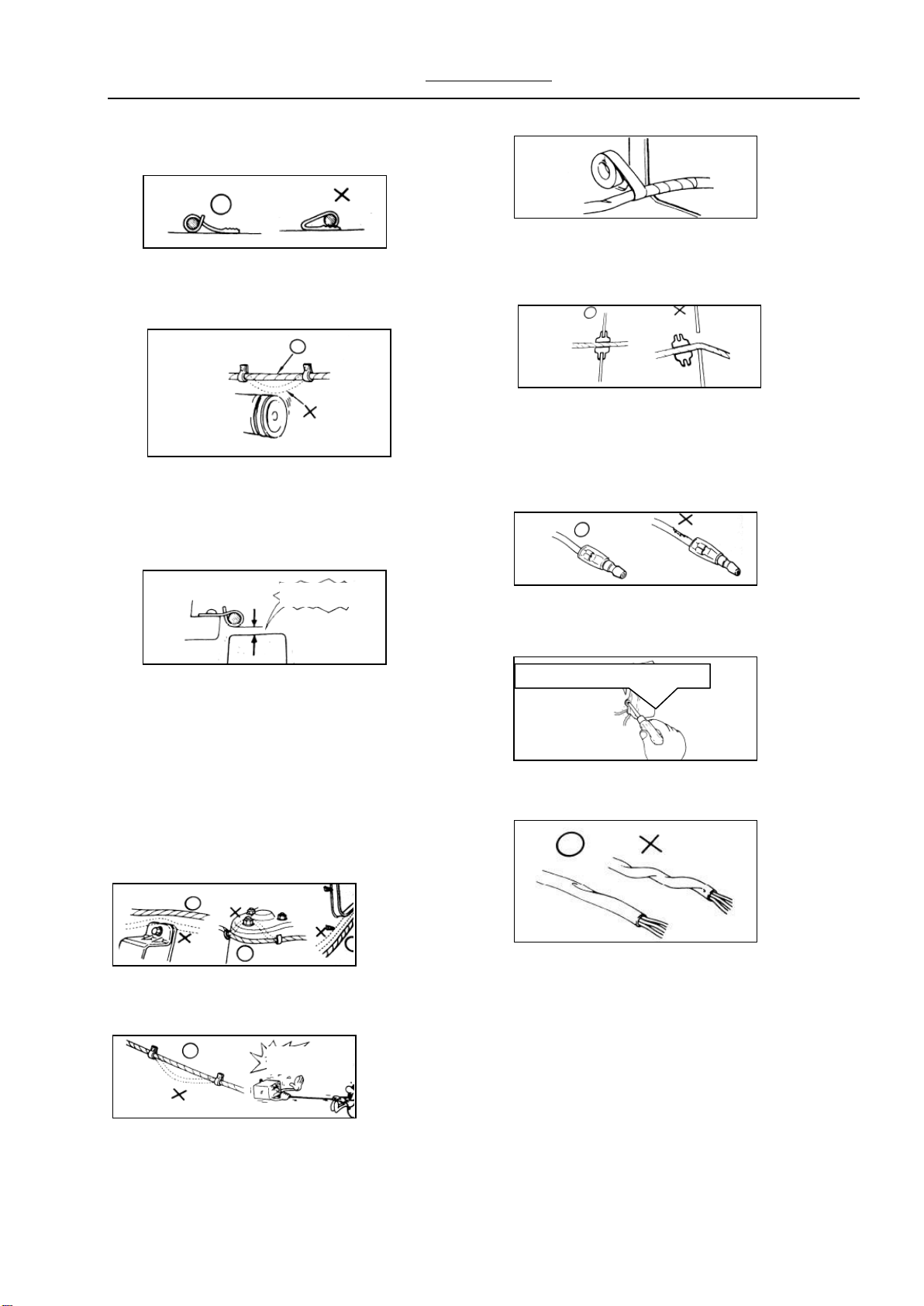

7. Before operating, always remove the negative (-)

end of the battery first and take care to prevent the

wrench or the like from touching the frame. After

operating, reconfirm all the connections, fixings

and junctions. If the battery is already removed,

connect the positive (+) end first.