YOKOGAWA DPharp EJXC80A User manual

User’s

Manual Diaphragm Seal System

EJXC80A, EJAC80E,

EJXC81A, EJAC81E,

EJXC50A and EJAC50E

IM 01C25W01-01EN

IM 01C25W01-01EN

3rd Edition

Toc-1

IM 01C25W01-01EN

Diaphragm Seal System

EJXC80A, EJAC80E, EJXC81A, EJAC81E, EJXC50A and

EJAC50E

IM 01C25W01-01EN 3rd Edition

3rd Edition: Oct. 2018 (YK)

All Rights Reserved, Copyright © 2016, Yokogawa Electric Corporation

Contents

1. Introduction............................................................................................... 1-1

Regarding This Manual................................................................................................ 1-2

Trademarks ................................................................................................................... 1-3

1.1 Safe Use of This Product ................................................................................. 1-3

1.2 Warranty............................................................................................................. 1-4

2. Handling Cautions.................................................................................... 2-1

2.1 ModelandSpecicationsCheck..................................................................... 2-1

2.2 Unpacking.......................................................................................................... 2-2

2.3 Storage............................................................................................................... 2-2

2.4 Selecting the Installation Location ................................................................ 2-2

2.5 Pressure Connection........................................................................................ 2-2

2.6 WaterproongofCableConduitConnections .............................................. 2-3

2.7 Restrictions on Use of Radio Transceivers ................................................... 2-3

2.8 Insulation Resistance and Dielectric Strength Test...................................... 2-3

3. Component Names .................................................................................. 3-1

4. Installation................................................................................................. 4-1

4.1 Precautions ....................................................................................................... 4-1

4.2 Mounting the Diaphragm Seals (Remote Seals) ........................................... 4-1

4.2.1 Mounting Flush type/Extended type Seals ........................................ 4-1

4.2.2 Mounting Inner Diaphragm Type Seals ............................................. 4-3

4.3 Mounting EJC80and EJC81with Remote Seal ................................ 4-3

4.5 Mounting EJC80with Direct Mount Seal ................................................. 4-5

4.5.1 Mounting ............................................................................................ 4-5

4.5.2 Connecting Impulse Piping to the Transmitter................................... 4-5

4.6 Mounting EJC50with Direct Mount Seal ................................................. 4-6

4.7 Mounting EJC50and EJC80with Hygienic Seal .............................. 4-7

4.7.1 Hygienic Seal (Flush Type) ................................................................ 4-7

4.7.2 Hygienic Seal (Extended Type) ........................................................ 4-7

4.7.3 Tank Spud Mounting Method............................................................. 4-8

Toc-2

IM 01C25W01-01EN

4.8 Rotating Transmitter Section......................................................................... 4-10

4.9 Changing Integral Indicator Direction .......................................................... 4-10

4.10 Mounting the Flushing Connection Ring ..................................................... 4-11

4.10.1 Mounting to Pressure Detector Section........................................... 4-11

4.10.2 Mounting to Process Flange ............................................................ 4-11

4.11 AfxingtheTeonFilm .................................................................................. 4-12

5. Operation................................................................................................... 5-1

5.1 Preparation for Starting Operation ................................................................. 5-1

5.2 Zero Point Adjustment ..................................................................................... 5-3

5.2.1 Zero point adjustment for Absolute Pressure Diaphragm Seal System

........................................................................................................... 5-4

5.3 Starting Operation ............................................................................................ 5-6

5.4 Shutting Down Operation ................................................................................ 5-6

5.5 Venting or Draining Transmitter Pressure-detector Section ....................... 5-6

5.5.1 Draining Condensate ......................................................................... 5-7

5.5.2 Venting Gas........................................................................................ 5-7

5.5.3 Draining Condensate for Flushing Connection Ring or Inner

Diaphragm Type Seal ........................................................................ 5-7

5.5.4 Venting Gas for Flushing Connection Ring or Inner Diaphragm Type

Seal .................................................................................................... 5-8

5.6 Local Parameter Setting................................................................................... 5-8

5.6.1 Local Parameter Setting (LPS) Overview.......................................... 5-9

5.6.2 Activating Local Parameter Setting ................................................. 5-10

5.6.3 Parameter Setting Review ............................................................... 5-10

5.6.4 TagNumberConguration............................................................... 5-11

5.6.5 PressureUnitConguration............................................................. 5-11

5.6.6 PressureLRV/URVConguration ................................................... 5-11

5.6.7 DampingTimeConstantConguration ........................................... 5-12

5.6.8 OutputModeConguration ............................................................. 5-12

5.6.9 DisplayOut1Conguration............................................................. 5-12

5.6.10 Re-range by applying actual pressure (LRV/URV).......................... 5-12

5.6.11 Save or Cancel................................................................................. 5-13

5.6.12 AbortConguration.......................................................................... 5-13

5.6.12.1 AbortConguration(Menu) ............................................ 5-13

5.6.12.2 AbortConguration(Parameter) .................................... 5-13

5.6.13 Local Parameter Setting Lock.......................................................... 5-13

5.6.14 Others .............................................................................................. 5-13

Toc-3

IM 01C25W01-01EN

When using the Transmitters in a Safety Instrumented Systems(SIS)

application, refer to Appendix A in either IM 01C25T01-06EN for the

HART protocol or IM 01C25T03-01E for the BRAIN protocol.

6. Maintenance.............................................................................................. 6-1

6.1 Overview ............................................................................................................ 6-1

6.2 CalibrationInstrumentsSelection .................................................................. 6-1

6.3 Calibration ......................................................................................................... 6-1

6.4 DisassemblyandReassembly ........................................................................ 6-4

6.4.1 Replacing the Integral Indicator ......................................................... 6-4

6.4.2 Replacing the CPU Board Assembly ................................................. 6-5

6.5 Replacing the Process Connector Gasket..................................................... 6-5

6.6 DisassemblyandReassemblyofConnectionAdapterofInnerDiaphragm

Type Seal............................................................................................................ 6-6

6.7 Troubleshooting................................................................................................ 6-6

6.7.1 Basic Troubleshooting ....................................................................... 6-6

6.7.2 Troubleshooting Flowcharts............................................................... 6-7

6.7.3 Alarms and Countermeasures........................................................... 6-9

7. GeneralSpecications ............................................................................ 7-1

7.1 StandardSpecications................................................................................... 7-1

Revision Information

<1. Introduction> 1-1

IM 01C25W01-01EN

1. Introduction

Thank you for purchasing the DPharp Pressure transmitter.

YourTransmitterwaspreciselycalibratedatthefactorybeforeshipment.Toensurebothsafetyandefciency,

please read this manual carefully before you operate the instrument.

This manual describes the diaphragm seal system that consists of a transmitter section and a pressure

detectorsection(diaphragmseal).Pleaseconrmthemodelandsufxcode(MScode)andthestylecodeof

the transmitter section on the product nameplate.

Pressure detector

section

F0101ai

Transmitter section

with flushing connection ring

Transmitter section

Pressure detector section

■ Differential Pressure Diaphragm Seal System

(High and low pressure remote seals)

Diaphragm Seal System

Differential pressure transmitter

Remote Mounted Diaphragm Seal (High pressure side)

Remote Mounted Diaphragm Seal (Low pressure side)

Flushing connection ring (High pressure side)*1

Flushing connection ring (Low pressure side)*1

■ Differential Pressure Diaphragm Seal System

(Single pressure remote seal)

Diaphragm Seal System

Differential pressure transmitter

Remote Mounted Diaphragm Seal (High pressure side)

Flushing connection ring (High pressure side)*1

■ Gauge/Absolute Pressure Diaphragm Seal System

Diaphragm Seal System

Gauge/Absolute pressure transmitter

Remote Mounted Diaphragm Seal (High pressure side)

Flushing connection ring (High pressure side)*1

■ Direct Mounted Diaphragm Seal System

Diaphragm Seal System

Differential/Gauge pressure transmitter

Direct Mounted Diaphragm Seal

Flushing connection ring*1

*1: Specify when a flushing connection ring is required.

Pressure detector section

Transmitter section

<1. Introduction>1-2

IM 01C25W01-01EN

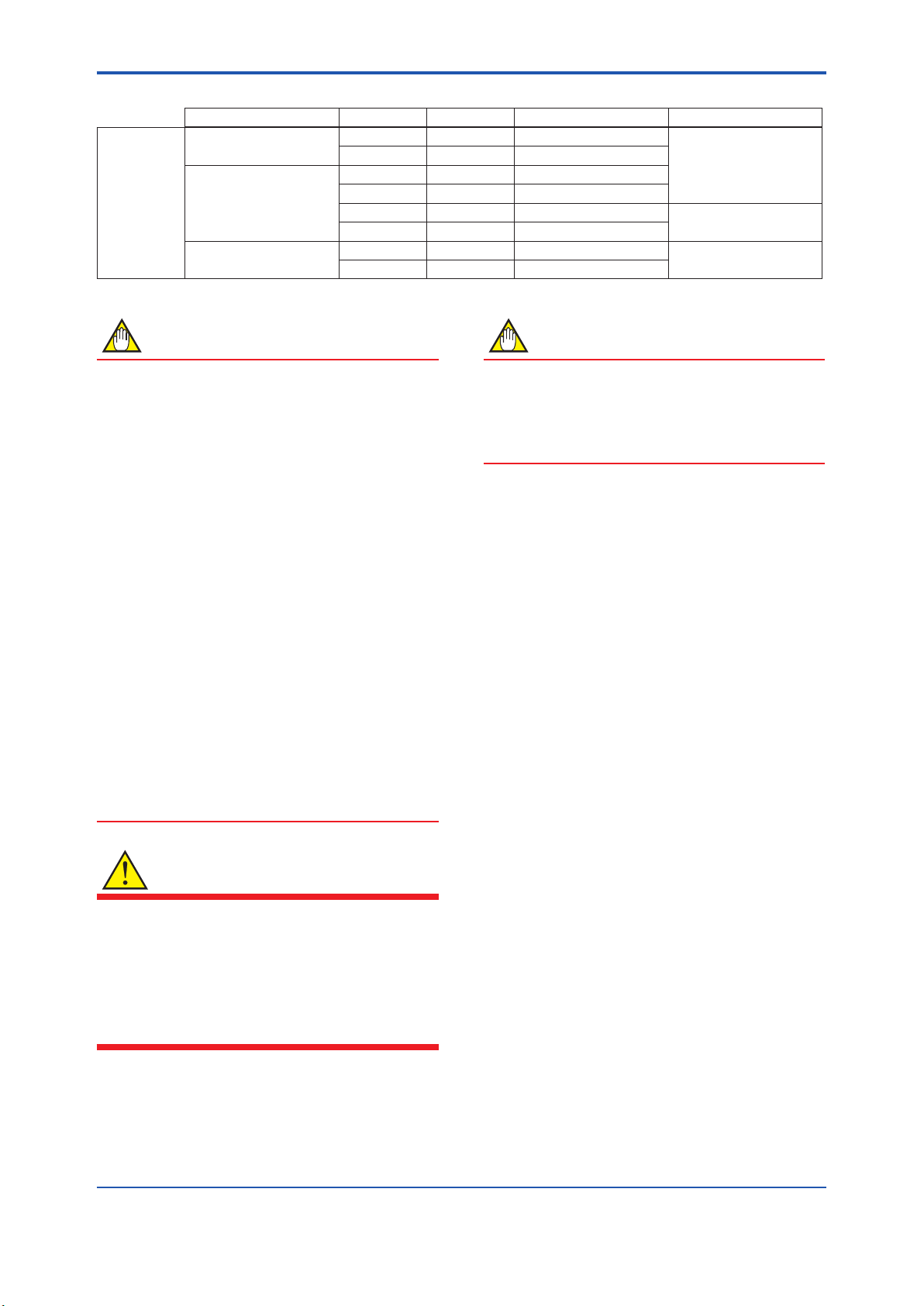

Table1.1 TransmitterModel

Transmitter Model Style code GS No. IM No.

Transmitter

section

Differential pressure

transmitter

EJX110A S3 GS 01C25B01-01EN

IM 01C25B01-01E

EJA110E S1, S2 GS 01C31B01-01EN

Gauge pressure

transmitter

EJX430A S2 GS 01C25E01-01EN

EJA430E S1, S2 GS 01C31E01-01EN

EJX530A S2 GS 01C25F01-01EN IM 01C25F01-01E

EJA530E S1, S2 GS 01C31F01-01EN

Absolute pressure

transmitter

EJX310A S2 GS 01C25D01-01EN IM 01C25B01-01E

EJA310E S1, S2 GS 01C31D01-01EN

NOTE

This manual describes the hardware

congurationsofthediaphragmsealsystem.

For wiring, please refer to the users’ manual(IM)

of each transmitter section as described in table

1.1 or “EJX/EJA-E series Installation Manual”(IM

01C25A01-01E) attached to the transmitter upon

shipment.

Forinformationonthesoftwareconguration

and operation, please refer to either

IM 01C25T03-01E for the BRAIN communication

type, or IM 01C25T01-06EN for the HART

communication type.

For FOUNDATION Fieldbus protocol type, please

refer to IM 01C25T02-01E.

For PROFIBUS PA protocol type, please refer to

IM 01C25T04-01EN.

To ensure correct use of this instrument, read

both the hardware and software manuals

thoroughly before use.

The manuals in pdf format are available on our

website (http://www.yokogawa.com/).

WARNING

When using the transmitters in a Safety

Instrumented Systems (SIS) application, refer

to Appendix 1 in either IM 01C25T01-06EN for

the HART protocol or IM 01C25T03-01E for the

BRAIN protocol. The instructions and procedures

in this section must be strictly followed in order to

maintain the transmitter for this safety level.

NOTE

When describing the model name like

EJC80, EJC81, or EJC50, it

shows the applicability for both EJXC80A

and EJAC80E, EJXC81A and EJAC81E, or

EJXC50A and EJAC50E respectively.

Regarding This Manual

• This manual should be provided to the end

user.

• The contents of this manual are subject to

change without prior notice.

• All rights reserved. No part of this manual may

be reproduced in any form without Yokogawa’s

written permission.

• Yokogawa makes no warranty of any kind with

regard to this manual, including, but not limited

to, implied warranty of merchantability and

tnessforaparticularpurpose.

• If any question arises or errors are found, or if

any information is missing from this manual,

please inform the nearest Yokogawa sales

ofce.

• Thespecicationscoveredbythismanualare

limited to those for the standard type under the

speciedmodelnumberbreak-downanddonot

cover custom-made instruments.

• Pleasenotethatchangesinthespecications,

construction, or component parts of the

instrumentmaynotimmediatelybereected

in this manual at the time of change, provided

that postponement of revisions will not cause

difcultytotheuserfromafunctionalor

performance standpoint.

<1. Introduction> 1-3

IM 01C25W01-01EN

• Yokogawa assumes no responsibility for this

product except as stated in the warranty.

• If the customer or any third party is harmed by

the use of this product, Yokogawa assumes

no responsibility for any such harm owing to

any defects in the product which were not

predictable, or for any indirect damages.

• The following safety symbols are used in this

manual:

WARNING

Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious

injury.

CAUTION

Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate

injury. It may also be used to alert against unsafe

practices.

IMPORTANT

Indicates that operating the hardware or software

in this manner may damage it or lead to system

failure.

NOTE

Draws attention to information essential for

understanding the operation and features.

Direct current

Functional grounding terminal

Caution

This symbol indicates that the operator must

refer to an explanation in the user’s manual

in order to avoid the risk of injury or death of

personnel or damage to the instrument.

Trademarks

• ‘DPharp’, ‘EJX’, ‘EJA’, ‘FieldMate’ and ‘BRAIN

TERMINAL’ are registered trademarks of

Yokogawa Electric Corporation. Company

names and product names used in this material

are registered trademarks or trademarks of their

respective owners.

• In this manual, trademarks or registered

trademarks are not marked with ™ or ®.

1.1 Safe Use of This Product

For the safety of the operator and to protect the

instrument and the system, please be sure to follow

this manual’s safety instructions when handling this

instrument. If these instructions are not heeded,

the protection provided by this instrument may be

impaired. In this case, Yokogawa cannot guarantee

that the instrument can be safely operated. Please

pay special attention to the following points:

(a) Installation

• This instrument may only be installed by an

engineer or technician who has an expert

knowledge of this device. Operators are not

allowed to carry out installation unless they

meet this condition.

• With high process temperatures, care must

be taken not to burn yourself by touching the

instrument or its casing.

• Never loosen the process connector nuts when

the instrument is installed in a process. This can

lead to a sudden, explosive release of process

uids.

• When draining condensate from the pressure

detector section, take appropriate precautions

to prevent the inhalation of harmful vapors and

thecontactoftoxicprocessuidswiththeskin

or eyes.

• When removing the instrument from a

hazardousprocess,avoidcontactwiththeuid

and the interior of the meter.

• All installation shall comply with local installation

requirements and the local electrical code.

<1. Introduction>1-4

IM 01C25W01-01EN

(b) Wiring

• The instrument must be installed by an

engineer or technician who has an expert

knowledge of this instrument. Operators are not

permitted to carry out wiring unless they meet

this condition.

• Before connecting the power cables, please

conrmthatthereisnocurrentowingthrough

the cables and that the power supply to the

instrument is switched off.

(c) Operation

• Wait 10 min. after the power is turned off, before

opening the covers.

(d) Maintenance

• Please carry out only the maintenance

procedures described in this manual. If you

require further assistance, please contact the

nearestYokogawaofce.

• Care should be taken to prevent the build up of

dust or other materials on the display glass and

the name plate. To clean these surfaces, use a

soft, dry cloth.

(e) ExplosionProtectedTypeInstrument

• Users of explosion protected type instruments

shouldreferrsttothesection“Installationof

an Explosion Protected Instruments” of the IM

(users’ manual) of the transmitter section.

• The use of this instrument is restricted to those

who have received appropriate training in the

device.

• Take care not to create sparks when accessing

the instrument or peripheral devices in a

hazardous location.

(f) Modication

• Yokogawa will not be liable for malfunctions or

damageresultingfromanymodicationmade

to this instrument by the customer.

(g) Product Disposal

• The instrument should be disposed of in

accordance with local and national legislation/

regulations.

1.2 Warranty

• The warranty shall cover the period noted on

the quotation presented to the purchaser at the

time of purchase. Problems occurring during

the warranty period shall basically be repaired

free of charge.

• If any problems are experienced with this

instrument, the customer should contact the

Yokogawa representative from which this

instrument was purchased or the nearest

Yokogawaofce.

• If a problem arises with this instrument,

please inform us of the nature of the problem

and the circumstances under which it

developed,includingthemodelspecication

and serial number. Any diagrams, data and

other information you can include in your

communication will also be helpful.

• Thepartyresponsibleforthecostofxingthe

problem shall be determined by Yokogawa

following an investigation conducted by

Yokogawa.

• The purchaser shall bear the responsibility for

repair costs, even during the warranty period, if

the malfunction is due to:

- Improper and/or inadequate maintenance by

the purchaser.

- Malfunction or damage due to a failure

to handle, use, or store the instrument in

accordancewiththedesignspecications.

- Use of the product in question in a location

notconformingtothestandardsspeciedby

Yokogawa, or due to improper maintenance

of the installation location.

- Failureordamageduetomodicationor

repair by any party except Yokogawa or an

approved representative of Yokogawa.

- Malfunction or damage from improper

relocation of the product in question after

delivery.

- Reasonofforcemajeuresuchasres,

earthquakes,storms/oods,thunder/

lightening, or other natural disasters, or

disturbances, riots, warfare, or radioactive

contamination.

<2. Handling Cautions> 2-1

IM 01C25W01-01EN

2. Handling Cautions

This chapter provides important information on how

to handle the transmitter. Read this carefully before

using the transmitter.

WARNING

The codes of the diaphragm seal system

represent a seal system type.

CEandotherstandardcerticationsareacquired

for each transmitter section.

Please refer to the designated sections of

each transmitter’s users’ manual(IM) for these

information as “Installation of an Explosion

Protected Instrument”, “EMC conformity standards”,

”Pressure Equipment Directive(PED)” and “Safety

Requirement Standards”.

Table2.1 TransmittersManualList

Diaphragm

Seal System

Applicable

Transmitter Users’ Manual(IM)

EJXC80A,

EJAC80E

EJX110A,

EJA110E,

EJX430A,

EJA430E IM 01C25B01-01E

EJXC81A,

EJAC81E

EJX310A,

EJA310E

EJXC50A,

EJAC50E

EJX530A,

EJA530E IM 01C25F01-01E

The transmitters are thoroughly tested at the

factory before shipment. When taking delivery of an

instrument, visually check them to make sure that

no damage occurred during shipment.

Also check that all the transmitter mounting

hardwareshowningure2.1isincluded.

If the transmitter is ordered without a mounting

bracket or a process connector, such mounting

hardware will not be included.

Mounting bracket

U-bolt nut

U-bolt

Transmitter

mounting bolt

F0201.ai

Process connector

Process connector gasket

Bolt

Figure 2.1 Transmitter Mounting Hardware

2.1 ModelandSpecications

Check

Themodelnameandspecicationsarewrittenon

the name plate attached to the case.

F0202.ai

Tag

Serial No. & Model

Figure 2.2 Name Plate

<2. Handling Cautions>2-2

IM 01C25W01-01EN

2.2 Unpacking

Keep the transmitter in its original packaging to

prevent it from being damaged during shipment.

Do not unpack the transmitter until it reaches the

installation site.

2.3 Storage

The following precautions must be observed when

storing the instrument, especially for a long period.

(a) Select a storage area which meets the following

conditions:

• It is not exposed to rain or subject to water

seepage/leaks.

• Vibration and shock are kept to a minimum.

• It has an ambient temperature and relative

humidity within the following ranges.

Ambient temperature:

–40* to 85°C without integral indicator

–30* to 80°C with integral indicator

*–15°Cwhen/HEisspecied.

Relative humidity:

0% to 100% R.H. (at 40°C)

Preferred temperature and humidity:

approx. 25°C and 65% R.H.

(b) When storing the transmitter, repack it carefully

in the packaging that it was originally shipped

with.

(c) If the transmitter has been used, thoroughly

cleanthechambersinsidethecoveranges

and the diaphragm surface of high pressure-

detector section, so that there is no process

uidremaininginsideoronit.Beforeplacingit

in storage, also make sure that the pressure-

detector section is securely connected to the

transmitter section.

2.4 Selecting the Installation

Location

The transmitter is designed to withstand severe

environmental conditions. However, to ensure

that it will provide years of stable and accurate

performance, take the following precautions when

selecting the installation location.

(a) Ambient Temperature

Avoid locations subject to wide temperature

variationsorasignicanttemperaturegradient.

If the location is exposed to radiant heat from

plant equipment, provide adequate thermal

insulation and/or ventilation.

(b) Ambient Atmosphere

Do not install the transmitter in a corrosive

atmosphere. If this cannot be avoided, there

must be adequate ventilation as well as

measures to prevent the leaking of rain water

and the presence of standing water in the

conduits.

(c) Shock and Vibration

Although the transmitter is designed to be

relatively resistant to shock and vibration, an

installation site should be selected where this is

kept to a minimum.

(d) Installation of Explosion-protected Transmitters

An explosion-protected transmitter is

certiedforinstallationinahazardousarea

containingspecicgastypes.Seesubsection

2.9 “Installation of an Explosion-Protected

Transmitters” of each transmitter’s manual as of

table 1.1.

2.5 Pressure Connection

WARNING

• Neverloosentheangeboltswhenan

instrument is installed in a process. The

device is under pressure, and a loss of seal

can result in a sudden and uncontrolled

releaseofprocessuid.

• Whendrainingtoxicprocessuidsthathave

condensed inside the pressure detector,

take appropriate steps to prevent the contact

ofsuchuidswiththeskinoreyesandthe

inhalationofvaporsfromtheseuids.

• Sincetheaccumulatedprocessuidmaybe

toxic or otherwise harmful, take appropriate

stepstopreventthecontactofsuchuids

with the skin or eyes and the inhalation

ofvaporsfromtheseuidsevenafter

dismounting the instrument from process line

for maintenance.

The following precautions must be observed

in order to safely operate the transmitter under

pressure.

(a) Make sure that all the process connector bolts

aretightenedrmly.

(b) Make sure that there are no leaks in the impulse

piping.

(c) Never apply a pressure higher than the

speciedmaximumworkingpressure.

<2. Handling Cautions> 2-3

IM 01C25W01-01EN

2.6 WaterproongofCable

Conduit Connections

Apply a non-hardening sealant to the threads

to waterproof the transmitter cable conduit

connections.

2.7 Restrictions on Use of Radio

Transceivers

IMPORTANT

Although the transmitter has been designed to

resist high frequency electrical noise, if a radio

transceiver is used near the transmitter or its

external wiring, the transmitter may be affected

by high frequency noise pickup. To test this, start

out from a distance of several meters and slowly

approach the transmitter with the transceiver

while observing the measurement loop for noise

effects. Thereafter use the transceiver outside

therangewherethenoiseeffectswererst

observed.

2.8 Insulation Resistance and

Dielectric Strength Test

Since the transmitter has undergone insulation

resistance and dielectric strength tests at the factory

before shipment, normally these tests are not

required. If the need arises to conduct these tests,

heed the following:

(a) Do not perform such tests more frequently than

is absolutely necessary. Even test voltages that

do not cause visible damage to the insulation

may degrade the insulation and reduce safety

margins.

(b) Never apply a voltage exceeding 500 V DC

(100 V DC with an internal lightning protector)

for the insulation resistance test, nor a voltage

exceeding 500 V AC (100 V AC with an internal

lightning protector) for the dielectric strength

test.

(c) Before conducting these tests, disconnect

all signal lines from the transmitter terminals.

The procedure for conducting these tests is as

follows:

• Insulation Resistance Test

1) Short-circuit the + and – SUPPLY terminals

in the terminal box. In case of 1 to 5 V output,

short-circuit the SUPPLY+, SUPPLY – and A

(VOUT +) terminals.

2) Turn OFF the insulation tester. Then connect

the insulation tester plus (+) lead wire to the

shorted SUPPLY terminals and the minus (–)

leadwire to the grounding terminal.

3) Turn ON the insulation tester power and

measure the insulation resistance. The voltage

shouldbeappliedasbrieyaspossibletoverify

thattheinsulationresistanceisatleast20MΩ.

4) After completing the test and being very careful

not to touch exposed conductors disconnect the

insulationtesterandconnecta100kΩresistor

between the grounding terminal and the short-

circuiting SUPPLY terminals. Leave this resistor

connected at least one second to discharge any

static potential. Do not touch the terminals while

it is discharging.

• Dielectric Strength Test

1) Short-circuit the + and – SUPPLY terminals

in the terminal box. In case of 1 to 5 V output,

short-circuit the SUPPLY+, SUPPLY – and A

(VOUT +) terminals.

2) Turn OFF the dielectric strength tester. Then

connect the tester between the shorted

SUPPLY terminals and the grounding terminal.

Be sure to connect the grounding lead of the

dielectric strength tester to the ground terminal.

3) Set the current limit on the dielectric strength

tester to 10 mA, then turn ON the power and

gradually increase the test voltage from ‘0’ to

thespeciedvoltage.

4) Whenthespeciedvoltageisreached,holdit

for one minute.

5) After completing this test, slowly decrease the

voltage to avoid any voltage surges.

<3. Component Names> 3-1

IM 01C25W01-01EN

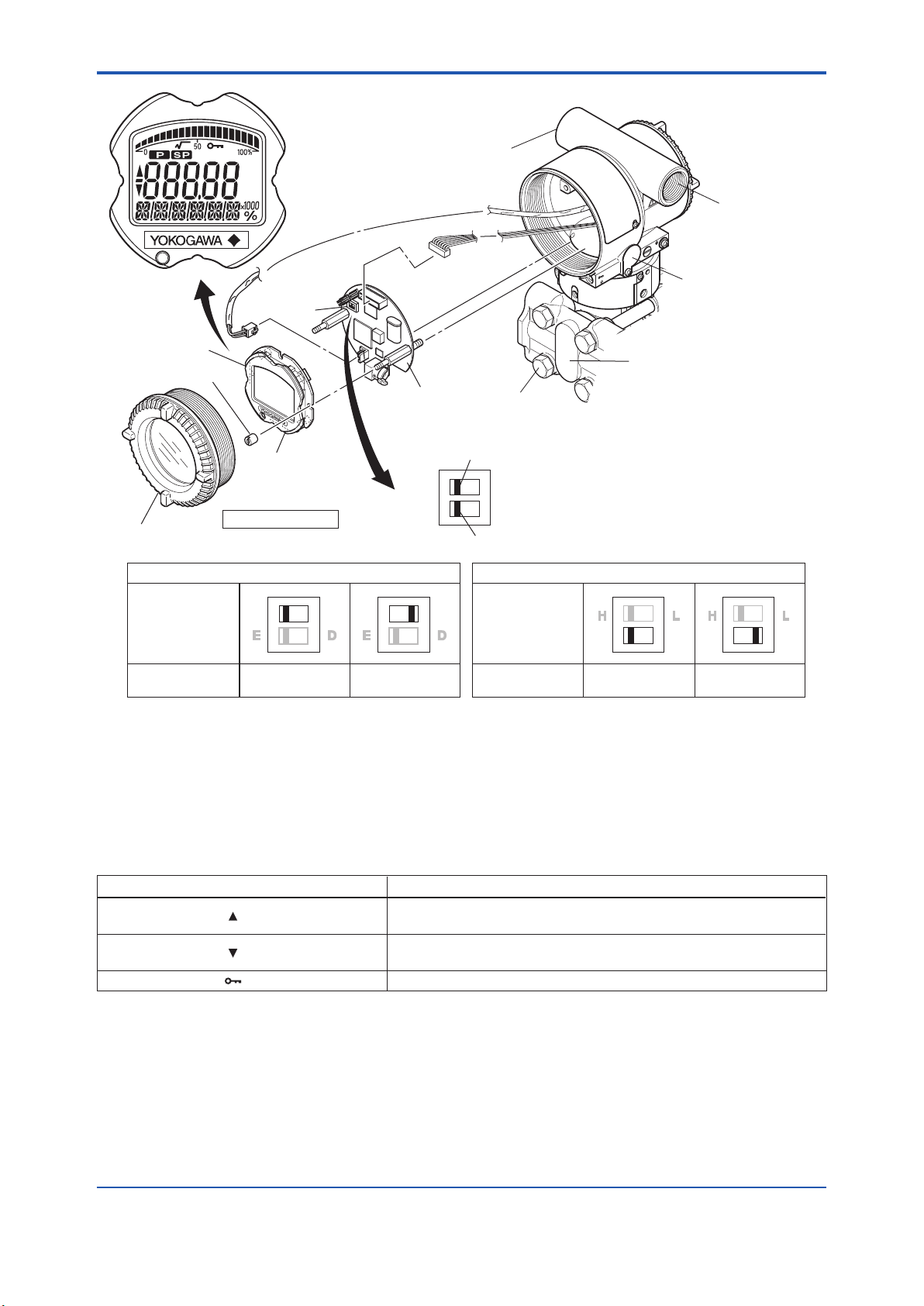

3. Component Names

EJC80Differential pressure transmitter

EJC80Differential pressure transmitter

Cover flange

Diaphragm seal

(high pressure side)

Diaphragm seal

(low pressure side)

Capillary tube

Pressure detector section

Transmitter section*

EJC80Pressure transmitter

EJC81Absolute Pressure transmitter

F0301.ai

Cover flange

Diaphragm seal

Pressure detector section

With C10FR

Flushing connection ring

C10FR

Flushing connection ring

Vent, drain plug

EJC50Pressure transmitter

Diaphragm seal

Pressure detector section

Diaphragm seal

(high pressure side)

Cover flange

Pressure detector section

*See figure 3.2. Transmitter section*

*See figure 3.2.

Transmitter section*

*See figure 3.2.

Transmitter section*

*See figure 3.2.

Vent, drain plug

Process connection

(low pressure side)

Process connector

EJC80Hygienic Differential pressure transmitter

Cover flange

Diaphragm seal

(high pressure side)

Diaphragm seal

(low pressure side)

Capillary tube

Transmitter section*

*See figure 3.2.

EJC80Hygienic pressure transmitter

Transmitter section*

*See figure 3.2.

Diaphragm seal

(high pressure side)

Cover flange

Pressure detector section

Vent, drain plug

Pressure detector section

Figure 3.1 Components Name(Figures Show Flush Type Diaphragm Seals)

<3. Component Names>3-2

IM 01C25W01-01EN

HIGH LOW

H L H L

F0302.ai

H L

E D

H L

E D

YES

(Write disabled)

NO

(Write enabled)

Slide switch

(Note 2)

Integral

indicator (Note 1)

Mounting screw

Amplifier Cover

Burnout direction switch (BO) Hardware write protection switch (WR)

Burnout Direction

Switch Position

Burnout Direction

Write Protection

Switch Position

Write Protection

Transmitter section

(Note 2) (Note 2)

CPU

assembly

Burnout direction switch

BO H L

WR E D

Write protection switch

Range-setting

switch (Note 1)

Zero-adjustment screw

Conduit connection

External indicator

conduit connection (Note 1)

Cover flange

(only for EJC80and EJC81)

Bolt for flange

(only for EJC80and EJC81)

Note1: See“ModelandSufxCodes”inchapter7fordetails.

Note2: ApplicableforBRAIN/HARTcommunicationtype.Settheswitchesasshowninthegureabovetosettheburn-outdirection

andwriteprotection.TheBurnoutswitchissettotheHsidefordelivery(unlessoptioncode/C1or/C2isspeciedintheorder),

andthehardwarewriteprotectionswitchissettoEside.Thesettingoftheswitchescanbeconrmedviacommunication.An

external zero adjustment screw can only be disabled by communication. To disable the screw, set a parameter before activating

the hardware write protect function. See each communication manual for details.

Figure 3.2 Component Names (Transmitter Section)

Table3.1 DisplaySymbol

Display Symbol Meaning of Display Symbol

The output signal being zero-adjusted is increasing.

Besides, this symbol lights when local parameter setting is in progress.

The output signal being zero-adjusted is decreasing.

Besides, this symbol lights when local parameter setting is in progress.

F0303.ai

Write protect function is enabled.

<4. Installation> 4-1

IM 01C25W01-01EN

4. Installation

4.1 Precautions

Before installing the transmitter, read the cautionary

notes in Section 2.4, “Selecting the Installation

Location.” For additional information on the

ambient conditions allowed at the installation

location, refer to in the chapter 7 “Standard

Specications.”

IMPORTANT

• When welding piping during construction,

take care not to allow welding currents to

owthroughthetransmitter.

• Do not step on this instrument after

installation.

• For the EJC80gauge transmitter, there

is a small hole in the low pressure side

coverangethatisusedtomeasurethe

atmospheric pressure.

The hole must not face upward. See

“Dimensions,” in the chapter 7 for the

location of the hole.

• Never loosen the four bolts securing the

coveranges(Refertogure3.2)for

EJC80and EJC81diaphragm seal

system.

If the seal liquid leaks, the transmitter cannot

be used.

4.2 Mounting the Diaphragm

Seals (Remote Seals)

4.2.1 MountingFlushtype/Extendedtype

Seals

Mountthediaphragmsealsusingtheangesas

shown in Figure 4.1 Figure 4.2 shows how to mount

thediaphragmsealsonatank.Thematingange,

gasket, bolts and nuts are to be procured by the

customer.

Nut

Flange

Diaphragm

Ød

Gasket

F0401.ai

Bolt

The product is shipped with

these parts assembled.

Correctly install the diaphragm seals on

the high and low pressure sides of the

process (The label on each diaphragm

seal is marked HIGH or LOW.)

Figure 4.1 Mounting the Diaphragm Seals

(Remote seal)

IMPORTANT

Please use a gasket with an inside diameter

(ød) that is greater than the diameter of the

diaphragm seal. If a gasket with a smaller

inside diameter is used, the diaphragm may not

function correctly. (Refer to ‘Dimensions’ in the

chapter 7.)

<4. Installation>4-2

IM 01C25W01-01EN

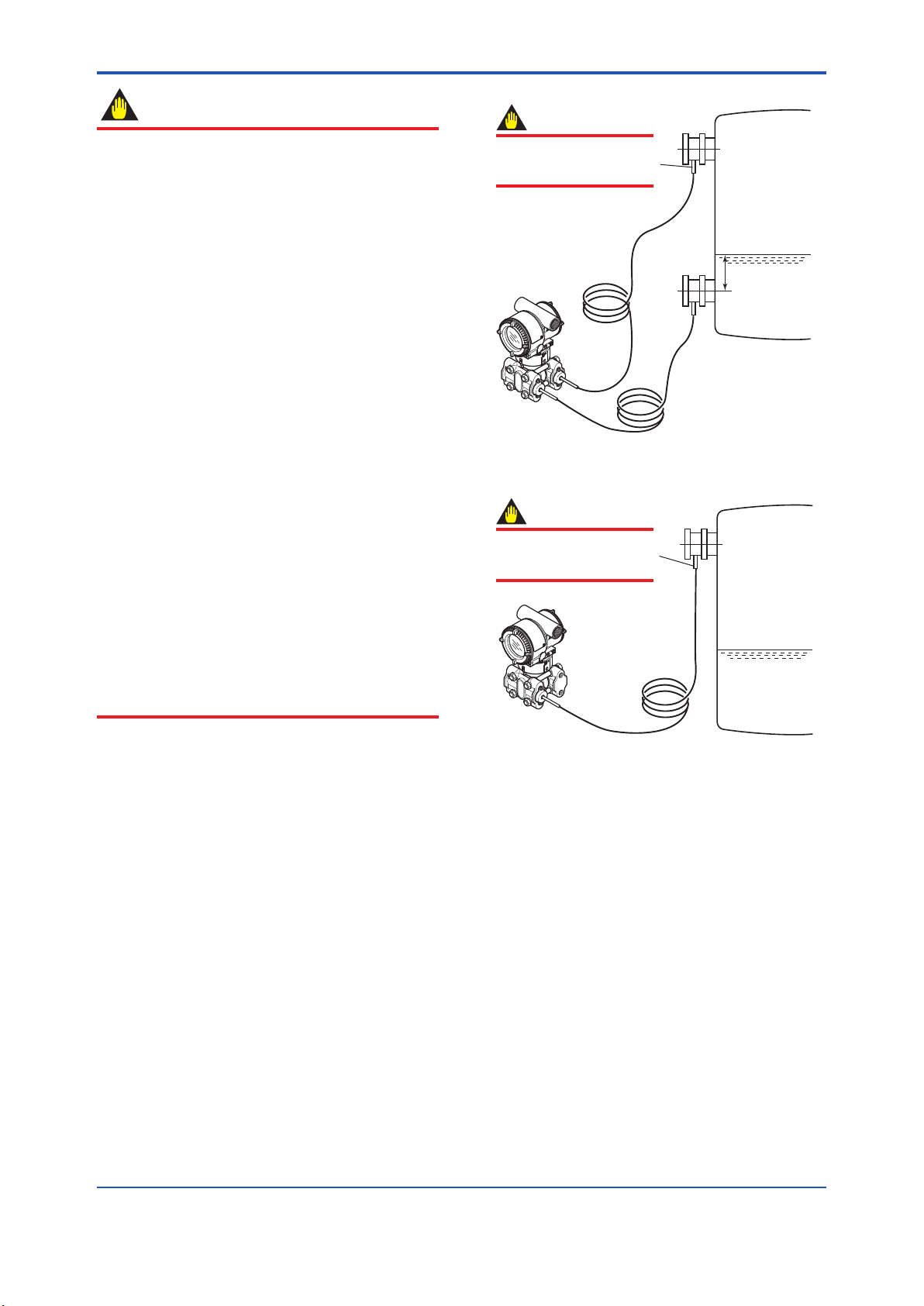

IMPORTANT

• When measuring the liquid level of the tank,

the minimum liquid level (zero point) must

be set to a level at least 50 mm above the

center of the high pressure side diaphragm

seal (see Figure 4.2).

• Correctly install the diaphragm seals on the

high and low pressure sides of the process,

checking the label on each seal.

• To avoid measuring error duets temperature

difference between the two diaphragm

seals, capillary tube must be bound together.

Thecapillarytubemustbesecurelyxed

to the tank wall to prevent movement by

wind or vibration. If the capillary tube is too

long, loosely coil the extra tube portion (coil

diameter of 300 mm or more) and secure the

coiled tube with a clamp.

• During the diaphragm seal installation,

ensure as far as possible that no seal liquid

head pressure is applied to the diaphragm

seals.

• Exercise care so as not to damage

diaphragm surfaces. Since the diaphragm

protrudesapprox.1mmfromtheange

surface, do not place the pressure detector

section face down on a surface as this can

damage the diaphragm.

• Do not sharply bend or twist capillary tube or

apply excessive stress to them.

F0402.ai

50mm minimum

Minimum

liquid level

High

pressure

side

Install the sealed diaphragm

so that the shank positions

downward.

Low

pressure

side

IMPORTANT

The transmitter should be

installed as low as possible

below the position where

the high pressure side

diaphragm seal is installed.

Install the sealed diaphragm

so that the shank positions

downward.

IMPORTANT

Figure 4.2 Installing the Diaphragm Seals to a

Tank

<4. Installation> 4-3

IM 01C25W01-01EN

4.2.2 Mounting Inner Diaphragm Type

Seals

Install the seal in accordance with the Figure 4.3.

Thebolts,nuts,matingangeandgasketaretobe

procured by the customer.

Position the connection adapter so that the drain/

vent plugs are aligned straight up and down.

IMPORTANT

• Please use the gasket whose inside

diameter is greater than the inside pipe

diameter.

• Do not sharply bend or twist capillary tube or

apply excessive stress to them.

• For differential pressure transmitters,

capillary tubes must be bundled together

to avoid measuring error duets temperature

difference between the two diaphragm seals.

• The product is performing temperature

compensation by the temperature sensor in

the transmitter section. When a difference

of temperature appears between the

transmitter section and capillary tube, an

output error occurs.

Please use thermal insulants to decrease the

effect of temperature difference between the

transmitter section and capillary tube.

Mating flange

Procured by the customer

Gasket

Procured by the customer

Connection flange

Connection adapter

Drain/vent plug

Capillary tube

Diaphragm

Gasket

Stud bolt/nut

Attached to product

Flange connection type

Adapter connection type

Mating flange

Procured by the customer

Gasket

Procured by the customer

Connection adapter

Drain/vent plug

Capillary tube

Diaphragm

Gasket

F0403.ai

Figure 4.3 Mounting Inner Diaphragm Seal

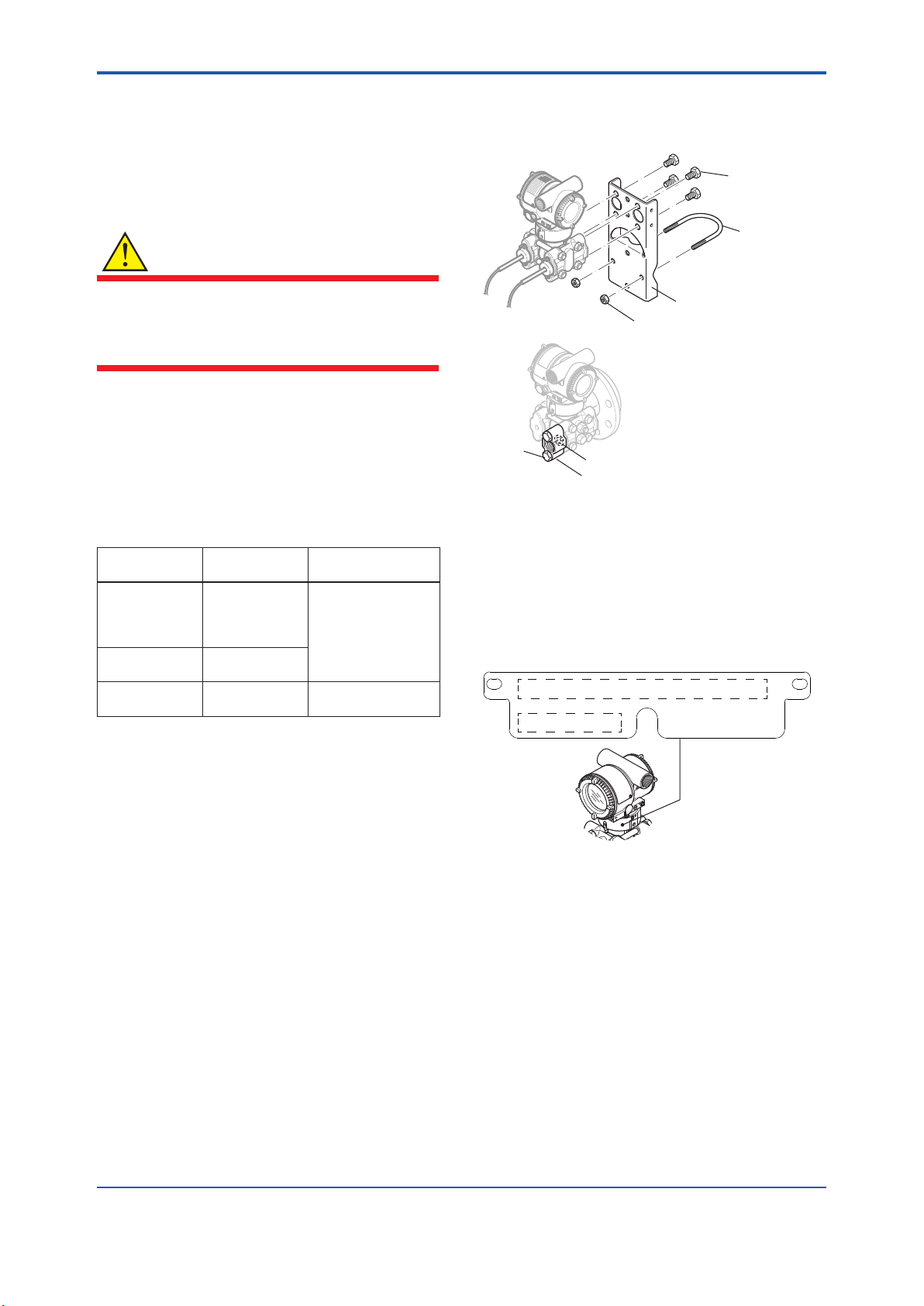

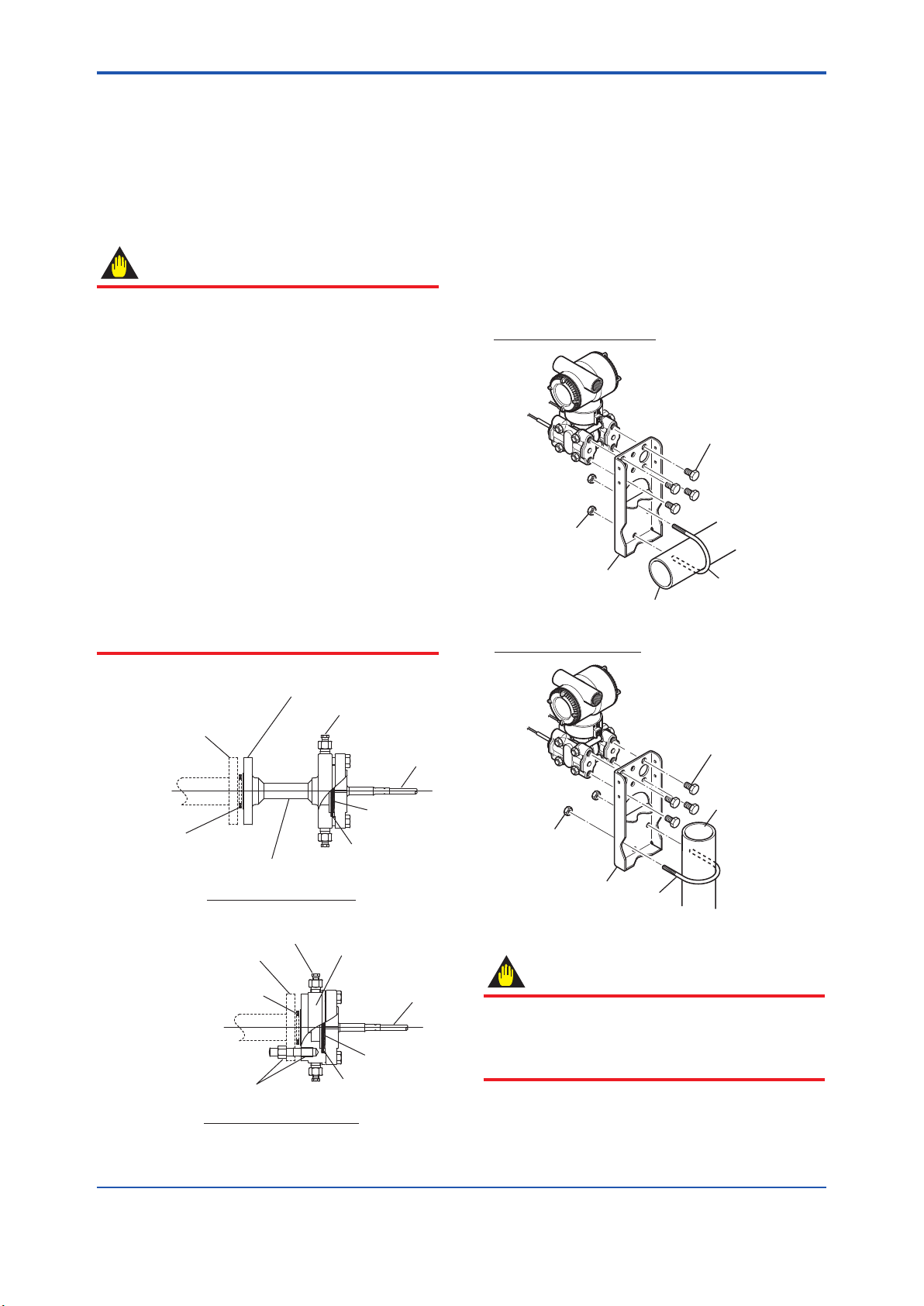

4.3 Mounting EJC80and

EJC81with Remote Seal

■ Thetransmittercanbemountedonanominal

50 mm (2 to inch) pipe using the mounting

bracket supplied, as shown in Figure 4.4.

The transmitter can be mounted on either a

horizontal or a vertical pipe.

■ Whenmountingthebracketonthetransmitter,

tighten the (four) bolts that hold the transmitter

to a torque of approximately 39 N·m {4 kgf·m}.

F0404.ai

U-bolt nut

Mounting bracket

Mounting bracket

50mm (2-inch) pipe

U-bolt

U-bolt

Horizontal pipe mounting

50mm (2-inch) pipe

Transmitter

mounting bolt

Transmitter

mounting bolt

U-bolt nut

Vertical pipe mounting

Figure 4.4 Transmitter Mounting

IMPORTANT

When using the absolute pressure transmitter of

M-Capsule, please care so that the sum of the

head pressure and atmospheric pressure does

not exceed Upper Range Limit (130 kPa abs.)

<4. Installation>4-4

IM 01C25W01-01EN

IMPORTANT

The transmitter should be installed at least

600 mm below the high pressure (HP) process

connection to ensure a positive head pressure

oflluid.Payspecialattentiontovacuum

applications.

If it can not be installed at least 600 mm below

the HP process connection, please use the

equation below:

h= × 0.102 [mm]

(P–P0)

ds

h: Vertical height between the HP process

connection and the transmitter (mm)

h≤0: Installthetransmitteratleasth(mm)

below the HP process connection

h>0: Install the transmitter at most h (mm)

above the HP process connection

P: Pressure in the tank (Pa abs)

P0: Minimum working pressure limit of the

transmitter (Pa abs). See below table.

[ForlluidcodeA,B,D,E,F,P]

Wetted parts

material code

Capillary

length

Process connection

size code

6 9

S

1 to 5 m 6790 3190

6 to 10 m 10030 3520

11 to 15 m 13310 3840

H

1 to 5 m 19150 6140

6 to 10 m 32090 8290

11 to 15 m -------- 10480

T

1 to 5 m 9620 3620

6 to 10 m 15090 4210

11 to 15 m -------- 4800

U

1 to 5 m 9540 4750

6 to 10 m 14930 6050

11 to 15 m -------- 7360

M

1 to 5 m 10910 3970

6 to 10 m 17380 4780

11 to 15 m -------- 5600

K

1 to 5 m 10910 3970

6 to 10 m 17380 4780

11 to 15 m -------- 5600

V

1 to 5 m 10910 3970

6 to 10 m -------- 4780

11 to 15 m -------- --------

J

1 to 5 m -------- 13070

6 to 10 m -------- 19540

11 to 15 m -------- --------

[Forlluidcode1,2,4]

Wetted parts

material code

Capillary

length

Process connection

size code

6 9

S1 to 5 m 2570 320

6 to 10 m 4680 530

H1 to 5 m 10220 2050

6 to 10 m 18650 3450

T1 to 5 m 4270 570

6 to 10 m 7780 960

ds: Specicgravityoflluid(at25°C).

See table 1 in the chapter 7.

F0405.ai

P

Low pressure side

High

pressure

side

(+)

(–)

0

h

Figure4.5 ExampleofInstallationtoTankfor

Differential Pressure Transmitter

(Caution on Installation)

F0406.ai

(+)

0

(–) P

h

Figure4.6 ExampleofInstallationtoTankfor

Gauge Pressure Transmitter

(Caution on Installation)

<4. Installation> 4-5

IM 01C25W01-01EN

4.5 Mounting EJC80with

Direct Mount Seal

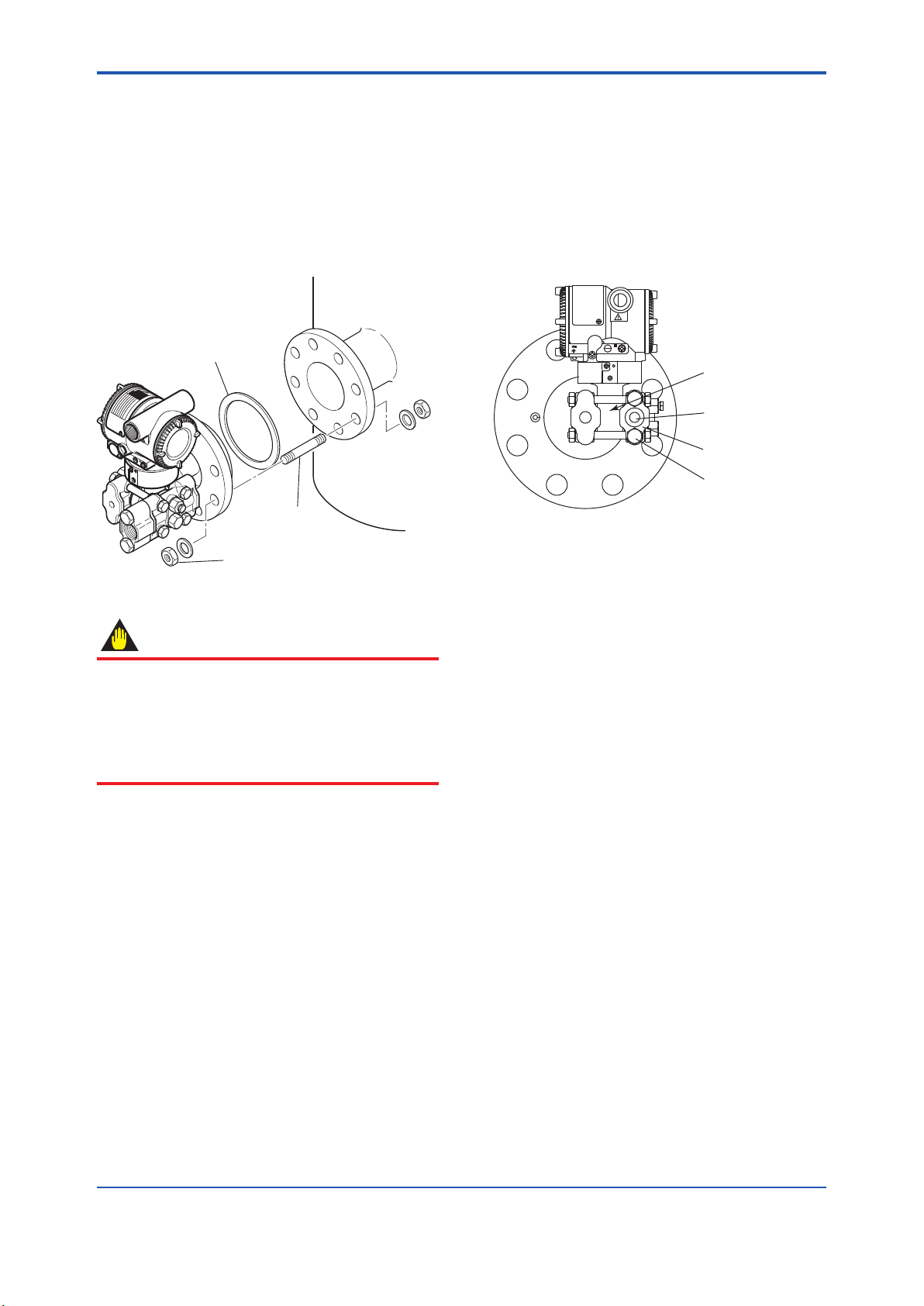

4.5.1 Mounting

The transmitter is mounted on a process using its

high-pressuresideangeasshowninFigure4.7.

Thematingange,gasket,studboltsandnutsare

to be procured by the customer.

F0407.ai

Gasket

Stud bolt

Nut

Figure 4.7 Transmitter Mounting

IMPORTANT

Please use a gasket with an inside diameter

(ød) that is greater than the diameter of the

diaphragm seal. If a gasket with a smaller

inside diameter is used, the diaphragm may not

function correctly. (Refer to ‘Dimensions’ in the

chapter 7.)

4.5.2 Connecting Impulse Piping to the

Transmitter

The impulse piping that connects the process

outputs to the transmitter must convey the process

pressure accurately. If, for example, gas collects in

aliquid-lledimpulseline,orthedrainofagas-lled

impulse line becomes plugged, it will not convey the

pressure accurately. Since this will cause errors in

the measurement output, select the proper piping

methodfortheprocessuid(gas,liquid,orsteam).

Pay careful attention to the following points when

routing the impulse piping and connecting the

impulse piping to a transmitter.

(1) Check the High and Low Pressure

Connections on the Transmitter (Figure 4.8)

The letters H and L on the capsule assembly

indicate the high and low pressure sides. For

liquid level measurement in an open tank, the low

pressure side measures atmospheric pressure.

For a closed tank, connect the impulse line to the

low pressure side of the transmitter to measure the

pressure in the tank.

F0408.ai

H and L appear here

Low pressure

connection

Process connector

Bolt

Figure4.8 HandLSymbolsonaCapsule

Assembly

(2) Tightening the Process Connector

Mounting Bolts

After connecting the impulse line, tighten the

process connector mounting bolts uniformly.

(3) Removing the Impulse Piping Connecting

Port Dustproof Cap

The impulse piping connecting port of the

transmitter is covered with a plastic cap to keep out

dust. This cap must be removed before connecting

the line. (Be careful not to damage the threads

when removing this cap. Never insert a screwdriver

or other tool between the cap and port threads to

remove the cap.)

(4) Impulse Piping Slope

The impulse piping must be routed with only an

upward or downward slope. Even for horizontal

routing, the impulse piping should have a slope of

at least 1/10 to prevent condensate (or gases) from

accumulating in the pipes.

(5) Preventing Freezing

Ifthereisanyriskthattheprocessuidinthe

impulse piping or transmitter could freeze, use a

steam jacket or heater to maintain the temperature

oftheuid.

<4. Installation>4-6

IM 01C25W01-01EN

NOTE

After completing the connections, close the

valves on the process pressure taps (main

valves), the valves at the transmitter (stop

valves), and the impulse piping drain valves,

so that condensate, sediment, dust and other

extraneous material cannot enter the impulse

piping.

(6) ImpulsePipingConnectionExamples

Figure 4.9 shows examples of typical impulse

piping connections. Before connecting the

transmitter to the process, study the transmitter

installation location, the process piping layout,

andthecharacteristicsoftheprocessuid

(corrosiveness,toxicity,ammability,etc.),etc.and

make appropriate changes and additions to the

connectioncongurations.

F0409.ai

Pipe (opened to atmosphere

at low pressure side)

Open Tank

Closed Tank

Tap valve

Union or flange

Vent plug

Tee

Drain valve

Drain plug

Figure4.9 ImpulsePipingConnectionExamples

4.6 Mounting EJC50with

Direct Mount Seal

The transmitter is mounted on a process using its

high-pressuresideangeasshowninFigure4.10.

Thematingange,gasket,studboltsandnutsare

to be procured by the customer.

F0410.ai

Gasket

Stud bolt

Nut

Figure 4.10 Transmitter Mounting

IMPORTANT

Please use a gasket with an inside diameter

(ød) that is greater than the diameter of the

diaphragm seal. If a gasket with a smaller

inside diameter is used, the diaphragm may not

function correctly. (Refer to ‘Dimensions’ in the

chapter 7.)

<4. Installation> 4-7

IM 01C25W01-01EN

4.7 Mounting EJC50and

EJC80with Hygienic

Seal

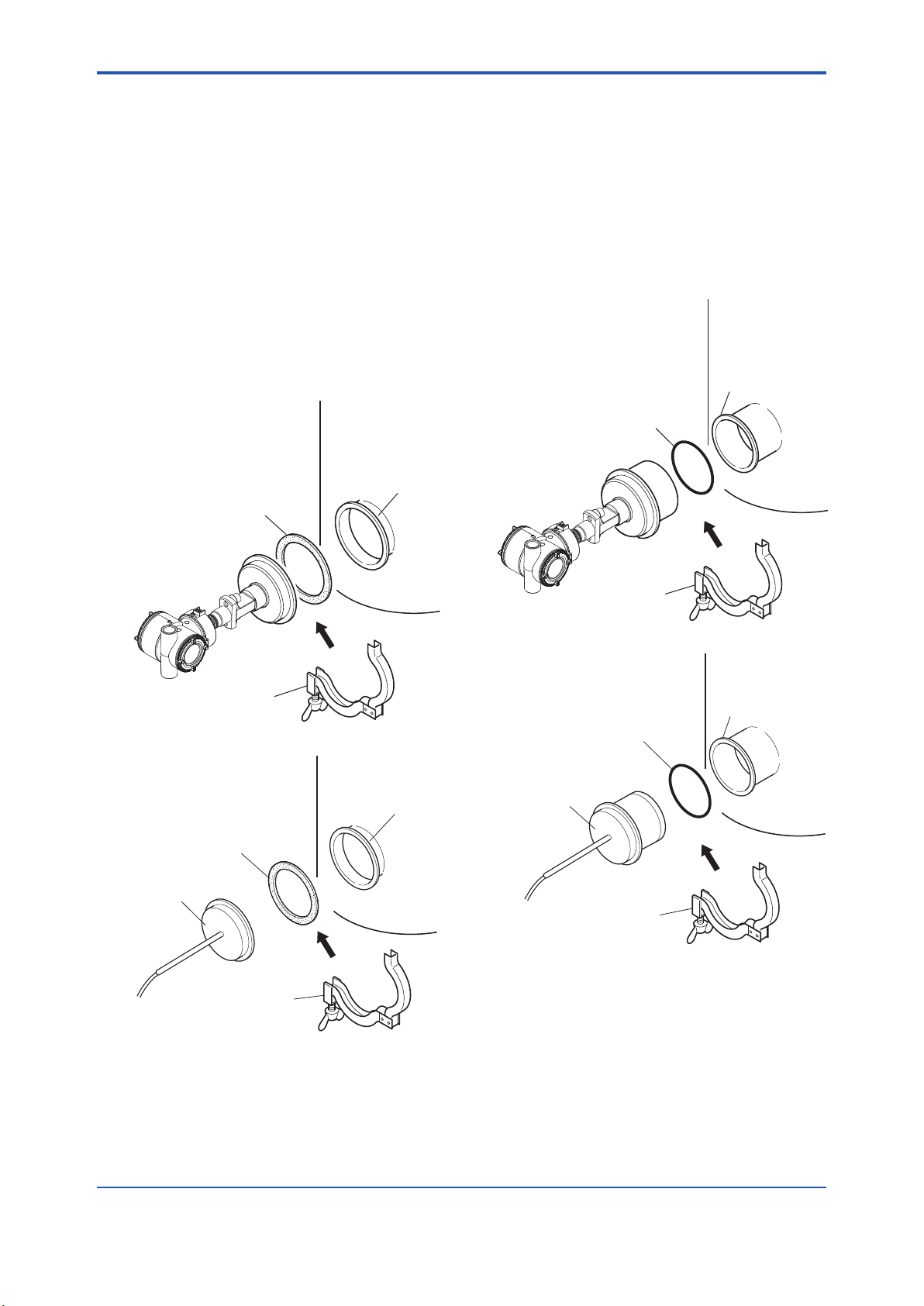

4.7.1 Hygienic Seal (Flush Type)

Theushdiaphragmtypeismountedonaprocess

tank as shown in Figure 4.11.

1) Fit the gasket into the gasket slot and attach it

to the transmitter .

2) With the gasket attached, mount the transmitter

onto the sleeve.

3) Use the clamp to secure the connecting section

in position.

F0411.ai

*: The customer should prepare

the mating gasket and clamp,

They are also available from

Yokogawa; if required, please

order them separately. Refer to

Table 4.2.

Tank

Sleeve

Gasket* (Optional)

Clamp* (Optional)

Tank

Sleeve

Gasket* (Optional)

Diaphragm seal

Clamp* (Optional)

Figure 4.11 Mounting Hygienic Seal (Flush Type)

4.7.2 HygienicSeal(ExtendedType)

The extended diaphragm type is mounted on a

process tank as shown in Figure 4.12.

1) Fit the O-ring into the O-ring slot of the

transmitter.

2) With the O-ring attached, mount the transmitter

onto the tank spud.

3) Use the clamp to secure the connecting section

in position.

F0412.ai

*: The customer should prepare the

mating O-ring, clamp, and tank

spud. They are also available

from Yokogawa; if required,

please order them separately.

Refer to Table 4.1 and 4.2.

Tank

Tank spud*

(sold separately)

O-ring* (Optional)

Clamp* (Optional)

Diaphragm seal

O-ring* (Optional)

Clamp* (Optional)

Tank

Tank spud*

(sold separately)

Figure4.12 MountingHygienicSeal(Extended

Type)

For the installation of a tank spud, read the following

section very carefully.

This manual suits for next models

5

Table of contents