York CS2000 Owner's manual

Other York Air Handler manuals

York

York MA Quick start guide

York

York F4FP024H06T3X User manual

York

York YBAH Series Instruction manual

York

York AE SERIES User manual

York

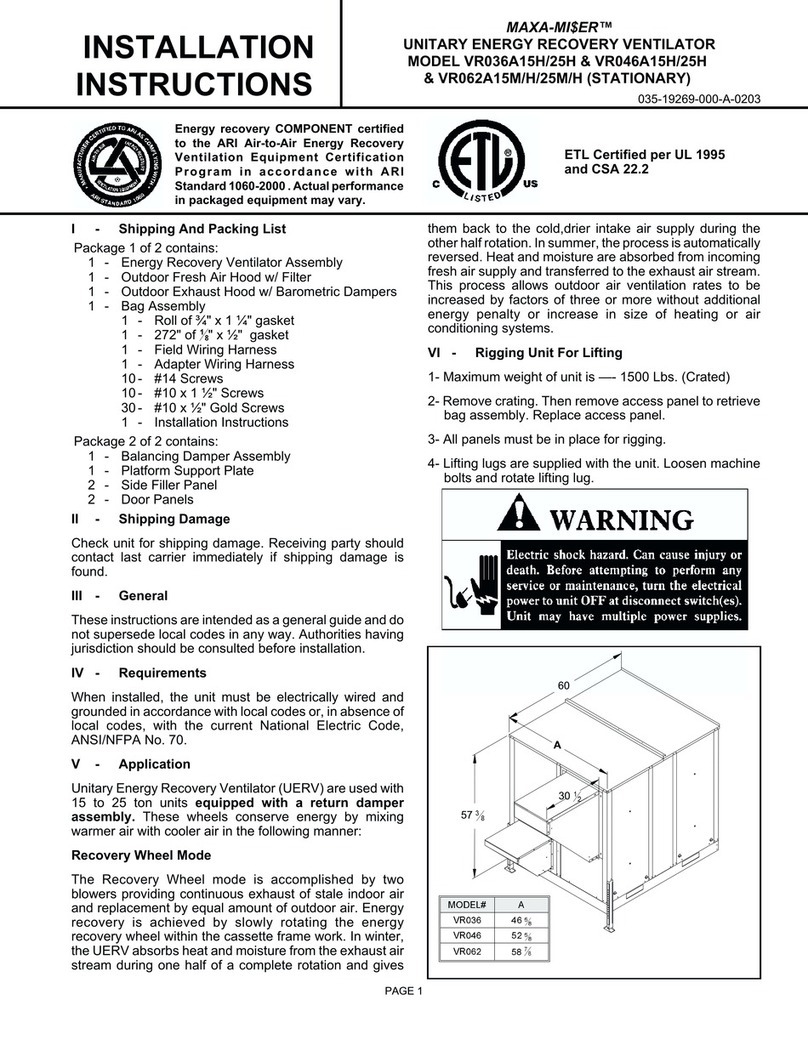

York MAXA-MISER VR036A15H User manual

York

York AHP18 THRU 60 Quick start guide

York

York AVY24 THRU 60 Quick start guide

York

York Solution Installation instructions

York

York 41HP AHR18B User manual

York

York ALL Guide

York

York YSHW Owner's manual

York

York AHR18B3XH21 Quick start guide

York

York AHP18 THRU 60 Quick start guide

York

York MX Series User manual

York

York MA - 115V User manual

York

York MCH CRAH User manual

York

York ZT SERIES Quick start guide

York

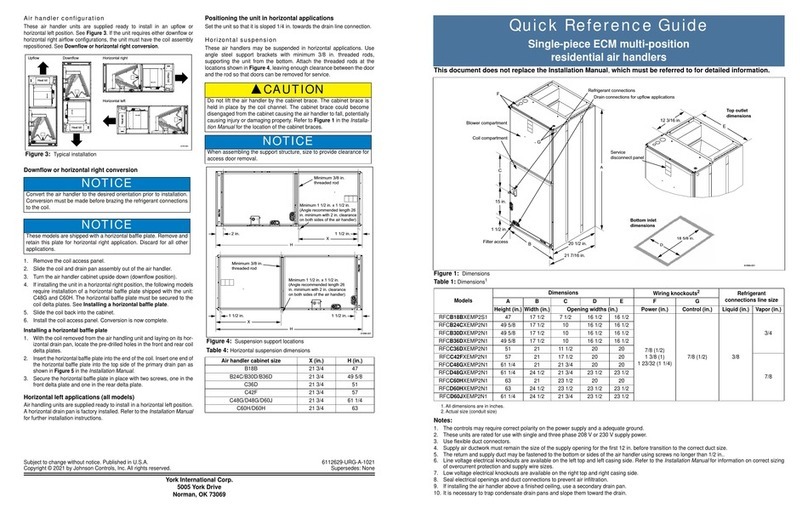

York RFCB18BXEMP2S1 User manual

York

York SOLUTION XTI Series Guide

York

York LDO9688 User manual

Popular Air Handler manuals by other brands

Klimor

Klimor EVO-S Operation and maintenance manual

Salda

Salda SMARTY XP MOUNTING AND INSTALLATION INSTRUCTION

BLAUBERG

BLAUBERG KOMFORT Roto EC S400 user manual

Trenton

Trenton TPLP Series installation instructions

Kemper

Kemper CleanAirTower operating manual

Daikin

Daikin DV PTC 14 Series installation instructions

Haier

Haier HB2400VA1M20 Installation & operation manual

Webasto

Webasto BlueCool A-Series operating instructions

RDZ

RDZ DA 701 Technical installation manual

Carrier

Carrier 39T Installation, Start-Up and Service Instructions

Armstrong Air

Armstrong Air BCE5V Series installation instructions

ActronAir

ActronAir CAY500T Installation and commissioning guide