- 4 -

■

EPDT-002f

■

4.2 Precautions during installation and inspection

Caution

(1)Please confirm that the direction of the fluid flow and the arrow on the product

coincide efore installing the product.

※The product will not function if it is installed in the wrong direction.

(2)Please support the piping and fix on the product securely.

※The product may deform y too much stress from the piping.

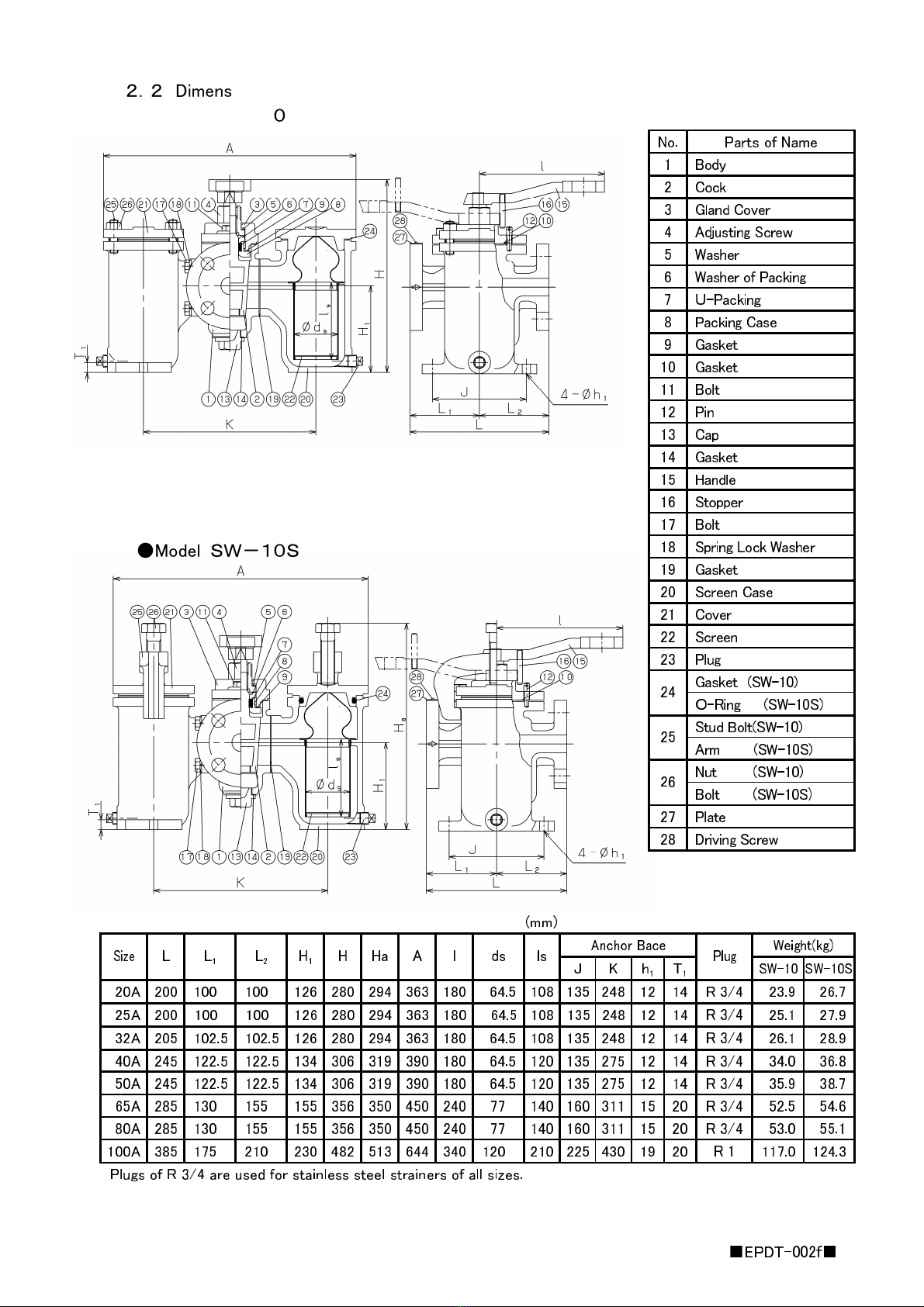

(3)Upon installation, please secure sufficient space as shown in 〔4.1 Example of

piping 【 Figure2 】 〕 for maintenance and inspection (including cleaning of the

screen).

※You will e una le to maintain (including cleaning of the screen) and inspect

the product if there is not enough space.

(4)Upon piping, please make sure that U

nnatural force, ending,or vi ration will not e

transmitted to the products.

※In adequate piping can result in leakage.

(5)Please make sure that the connections with the piping are secure.

※Inadequate connections can result in physical damages due to fluid outflow

caused y vi rations and other reasons.

※Inadequate connections can result in fluid outflow.

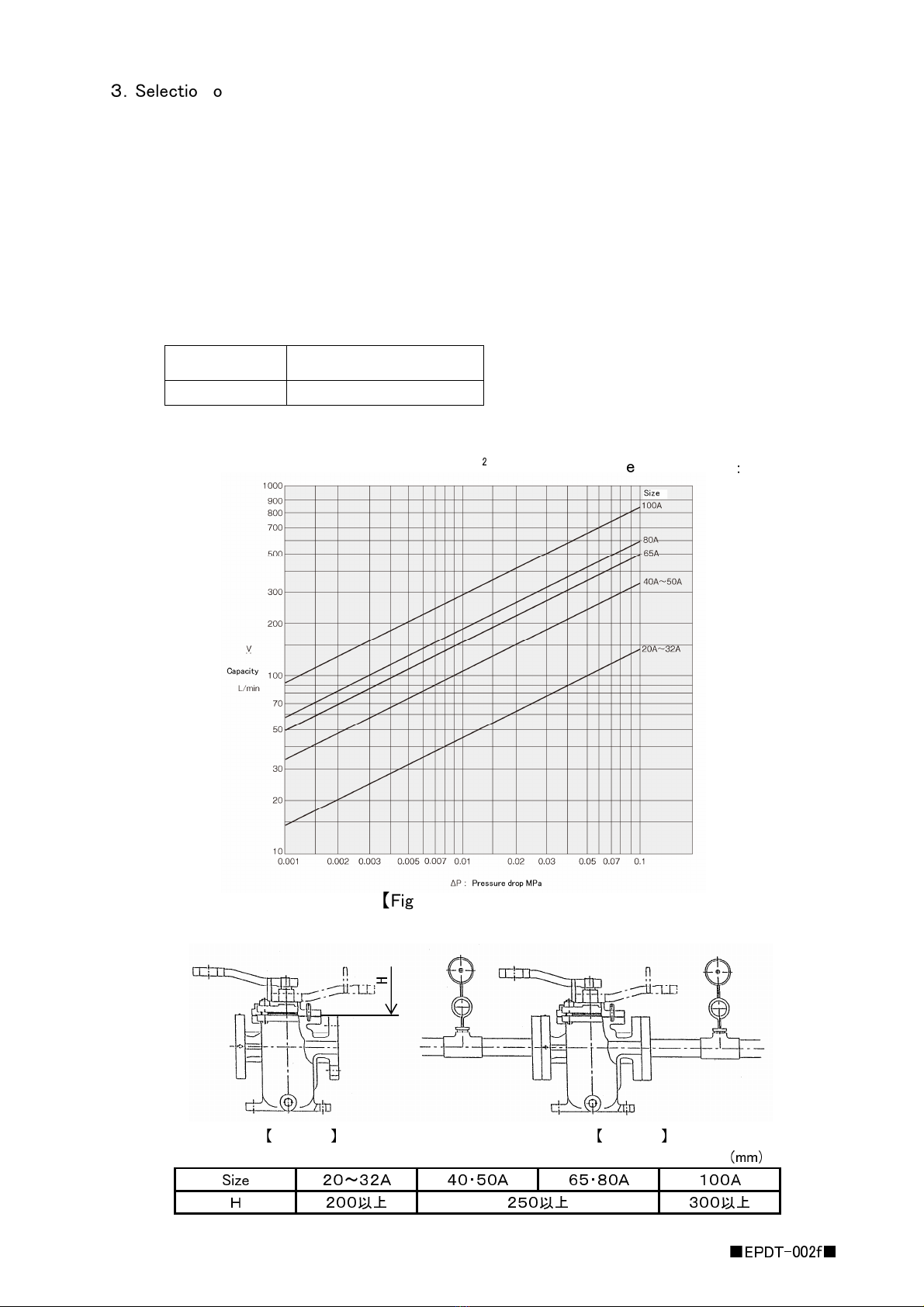

(1)Installiing pressure gauges at inlet and outlet side may help to detect the clogging

upof the screen.〔4.1 Example of piping【Figure3】〕

(2)When using at outside,painting is needed to avoid from the rust.

5.Operation

5.1 Warning and caution upon operation

Warning

(1)Please make sure that there is no danger at the pipe end efore pouring the fluid.

※You may get scalded in case hot fluid spouts out.

※Physical damage may occur from fluid outflow.

Caution

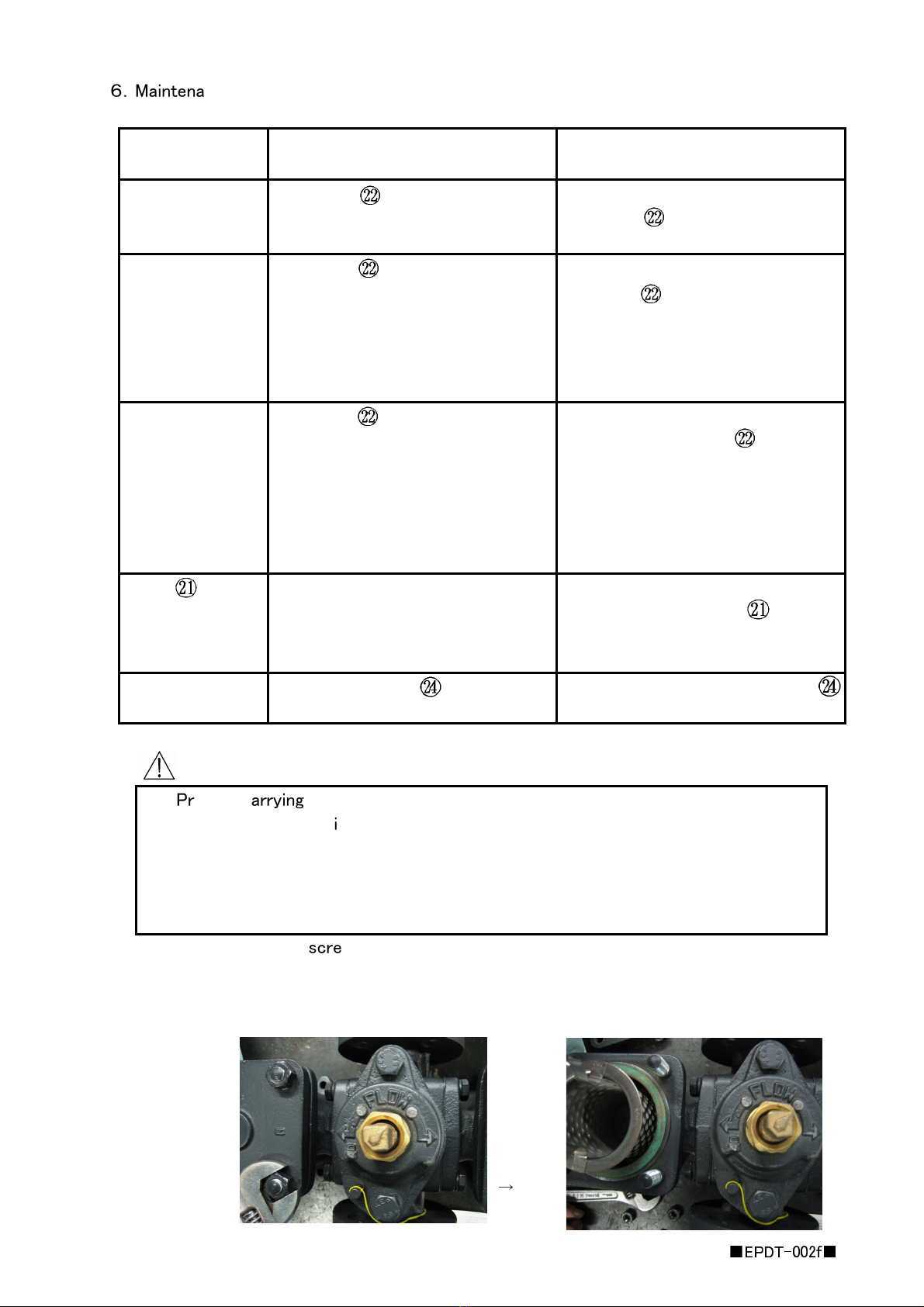

(1)Use the strainer in condition of maximum pressure loss of elow 0.1MPa.Also

keep cleaning the screen periodically.

※The Screen may e damaged.

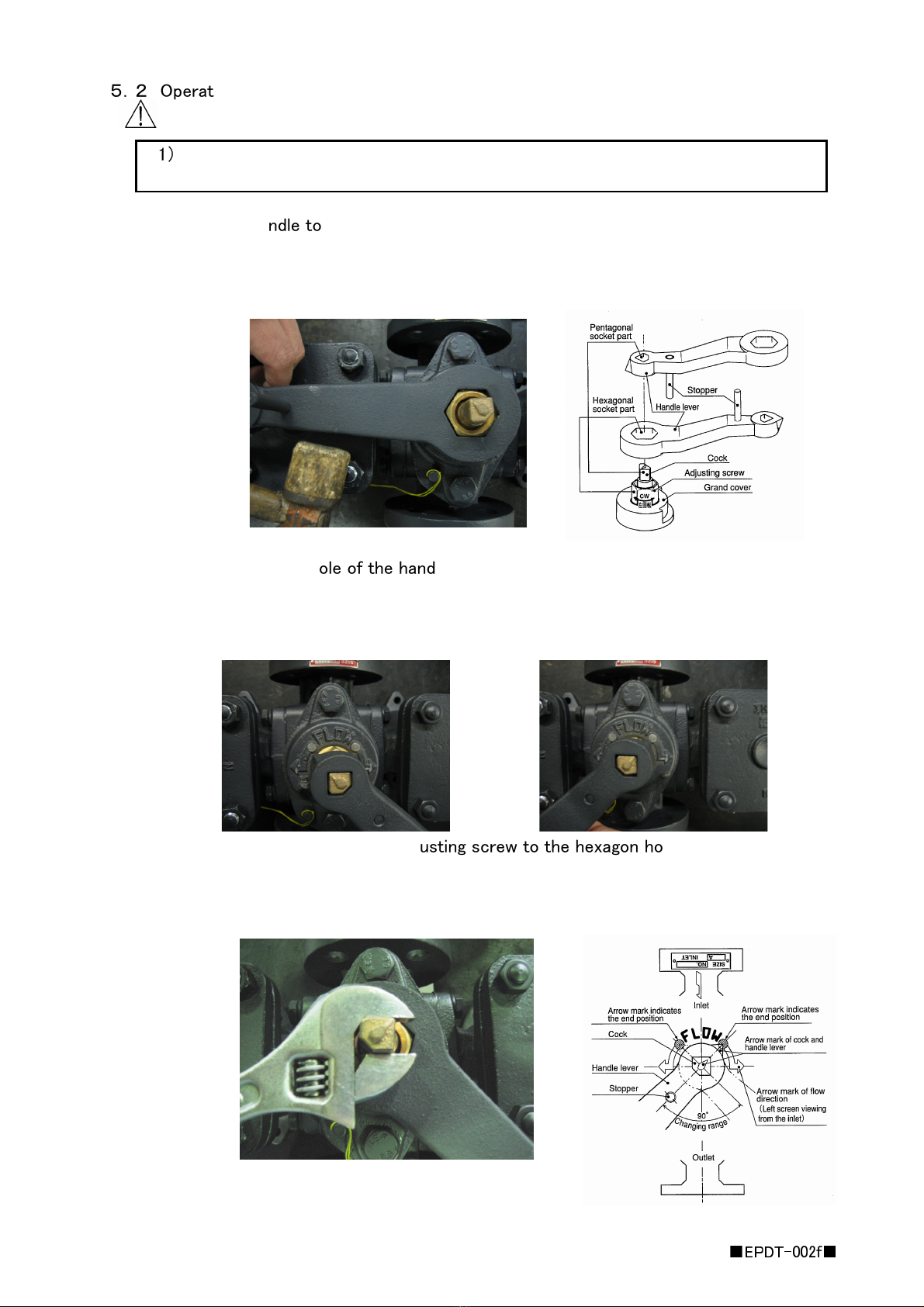

(2)Always follow the sequence when switching the cock.

※The product may not work properly.〔5.2 Operation method Reference〕

(3)

There are some allowa le leakages from the cock, so when cleaning the screen,

please take off

the plug under the screen case,and install the low valve to

release the fluid to the safety place.

(1)When cock and adjusting screw trun at the same time, please fix the cock with

wrench and turn the adjusting screw.

※May not o tain the proper pressure drop or filtration a ility.

(2)Do not tighten the adjusting screw with excessive torque.

※It may cause the reakage on cock and sdjusting screw.