■EPDT-201g■

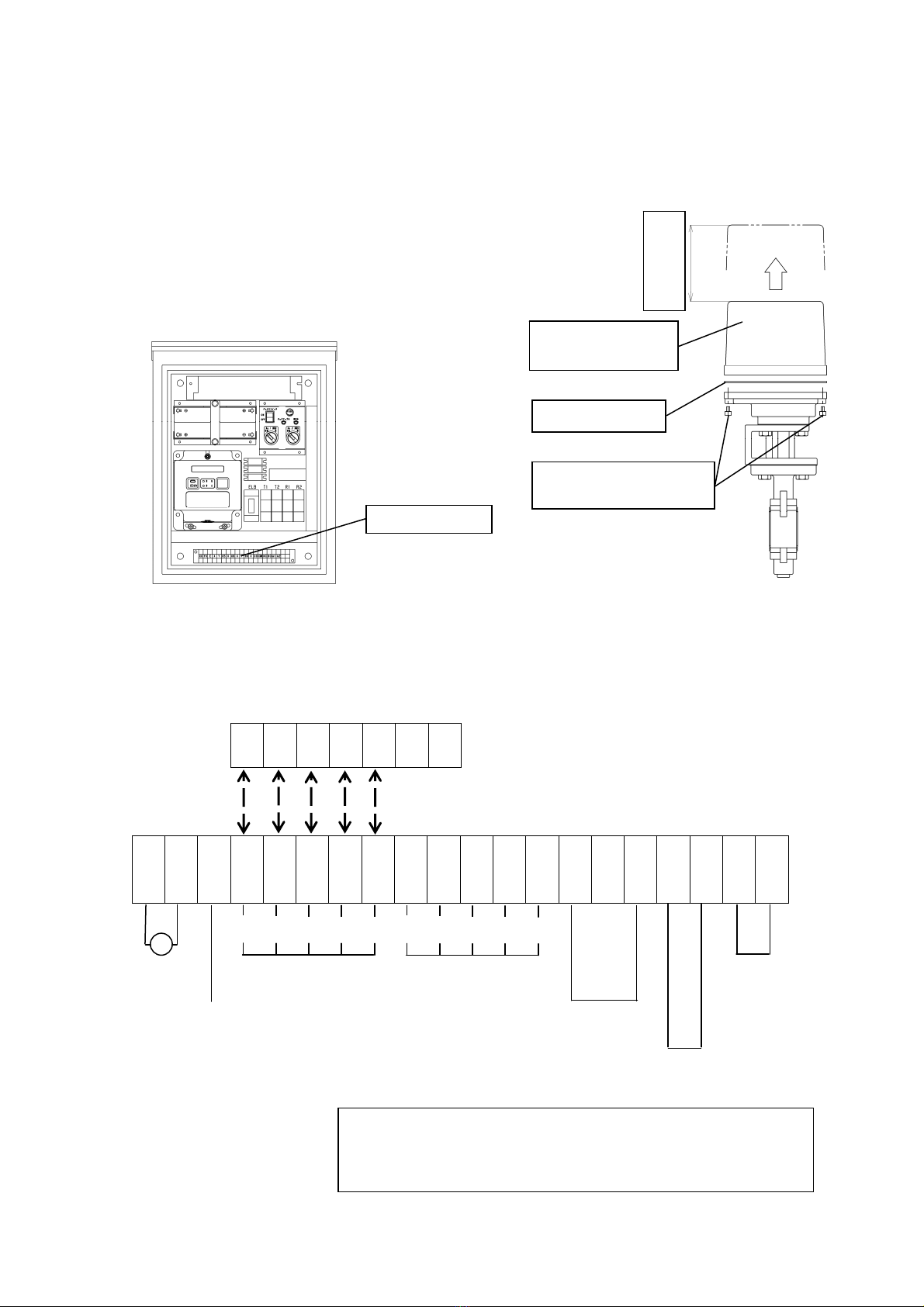

Water receiving tank and high placement water tank application

Emergency shut-off system

Type MD-71 Emergency shut-off valve

Type KS-5 Emergency shut-off valve control panel

Operation manual

Thank you very much for purchasing this product from Yoshitake. To use the purchased product on a

correct and safe basis, read this text before using it. In addition, the user customer is to store this

document carefully.

Responsibility for a failure of the product caused by improper handling will be assumed by the customer.

In this case, the product will be replaced or repaired at the customer's expense.

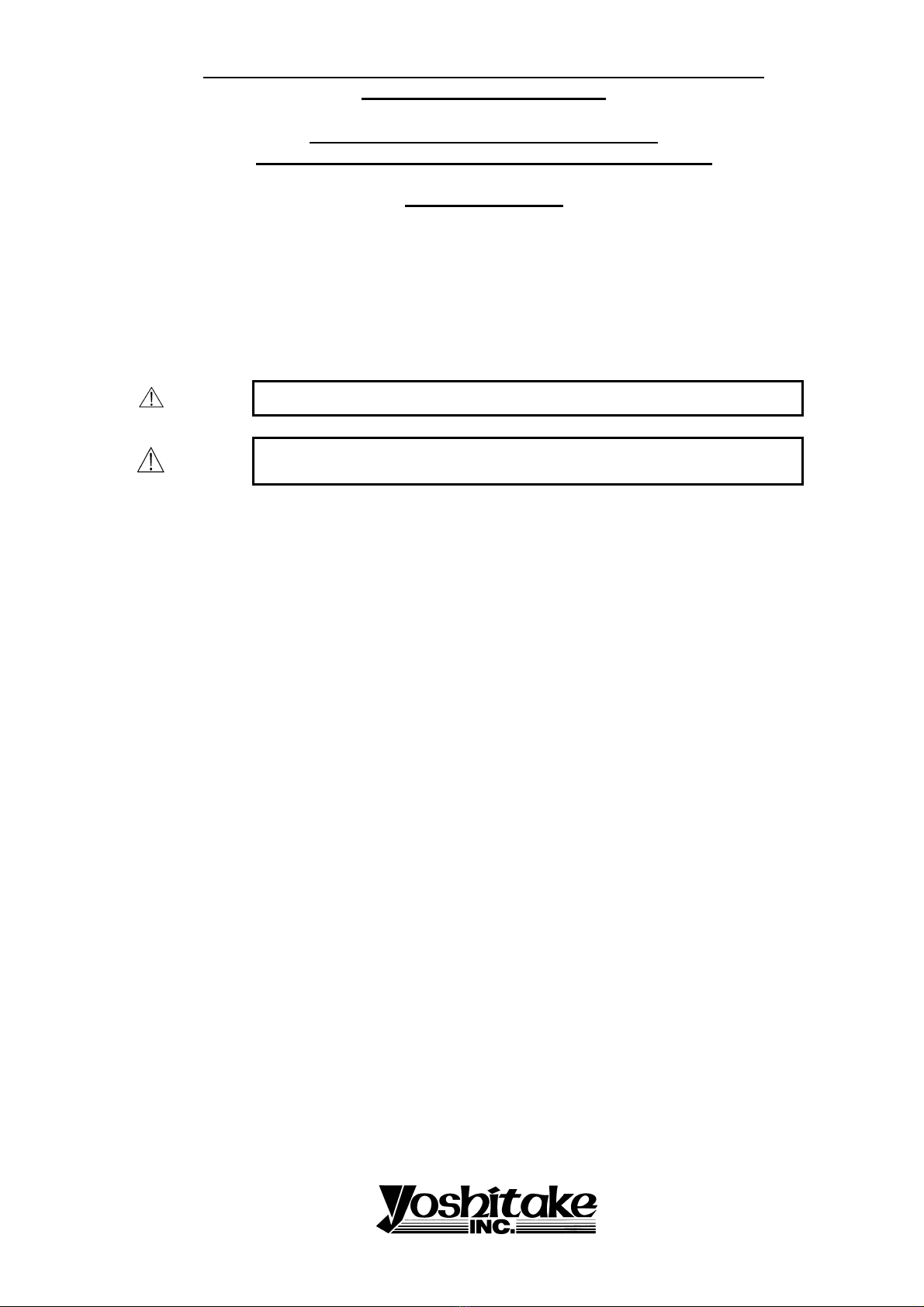

----- Symbols used in this text refer to the following: -----

Warning Improper handling may cause the user to be killed or seriously injured

Caution Improper handling may cause the user to be slightly injured or the

equipment to be damaged

Table of contents

1. Product application ····················································································1

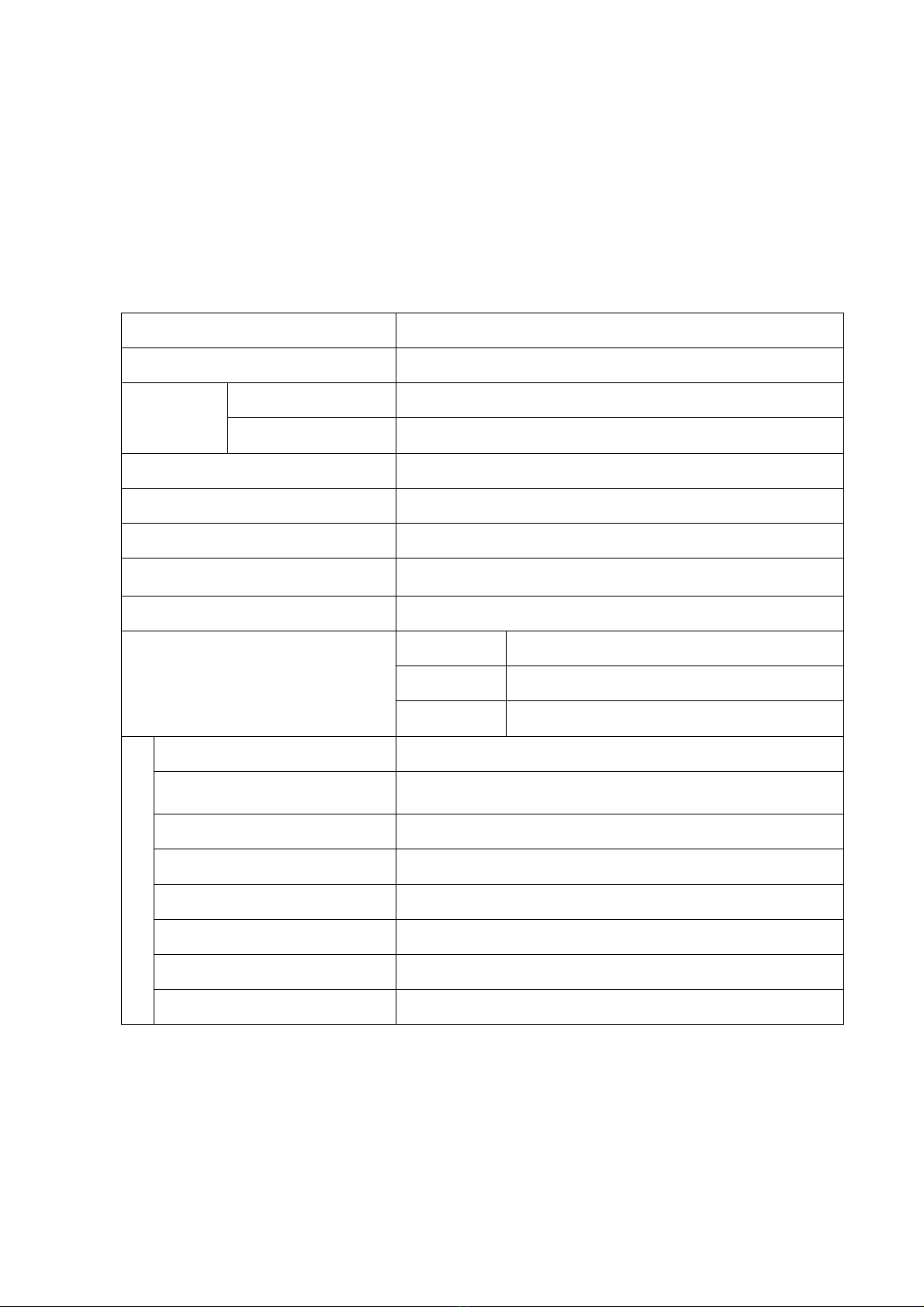

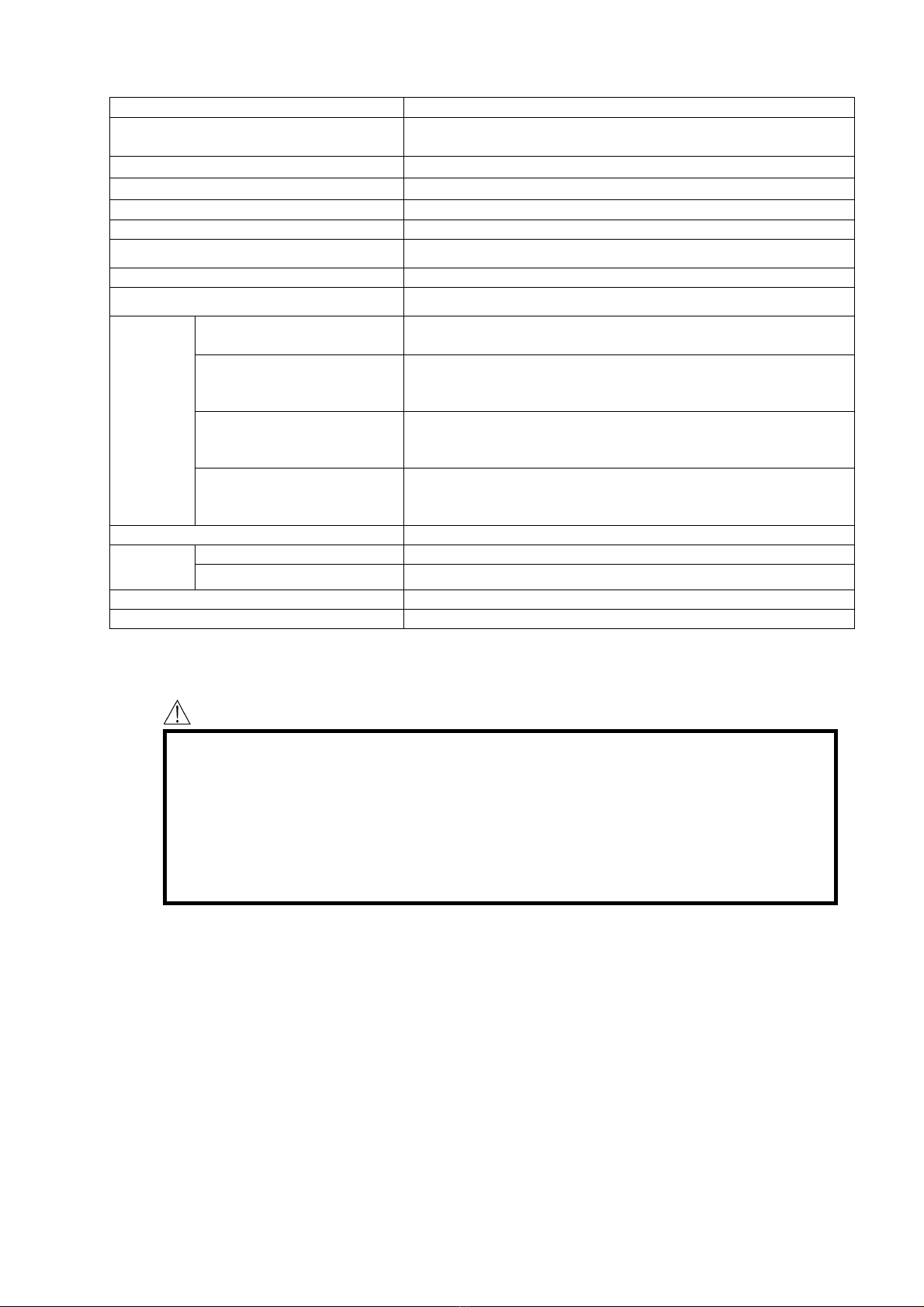

2. Specifications

2.1 Specifications for the emergency shut-off valve ····································1

2.2 Specifications for the emergency shut-off valve control panel ···············2

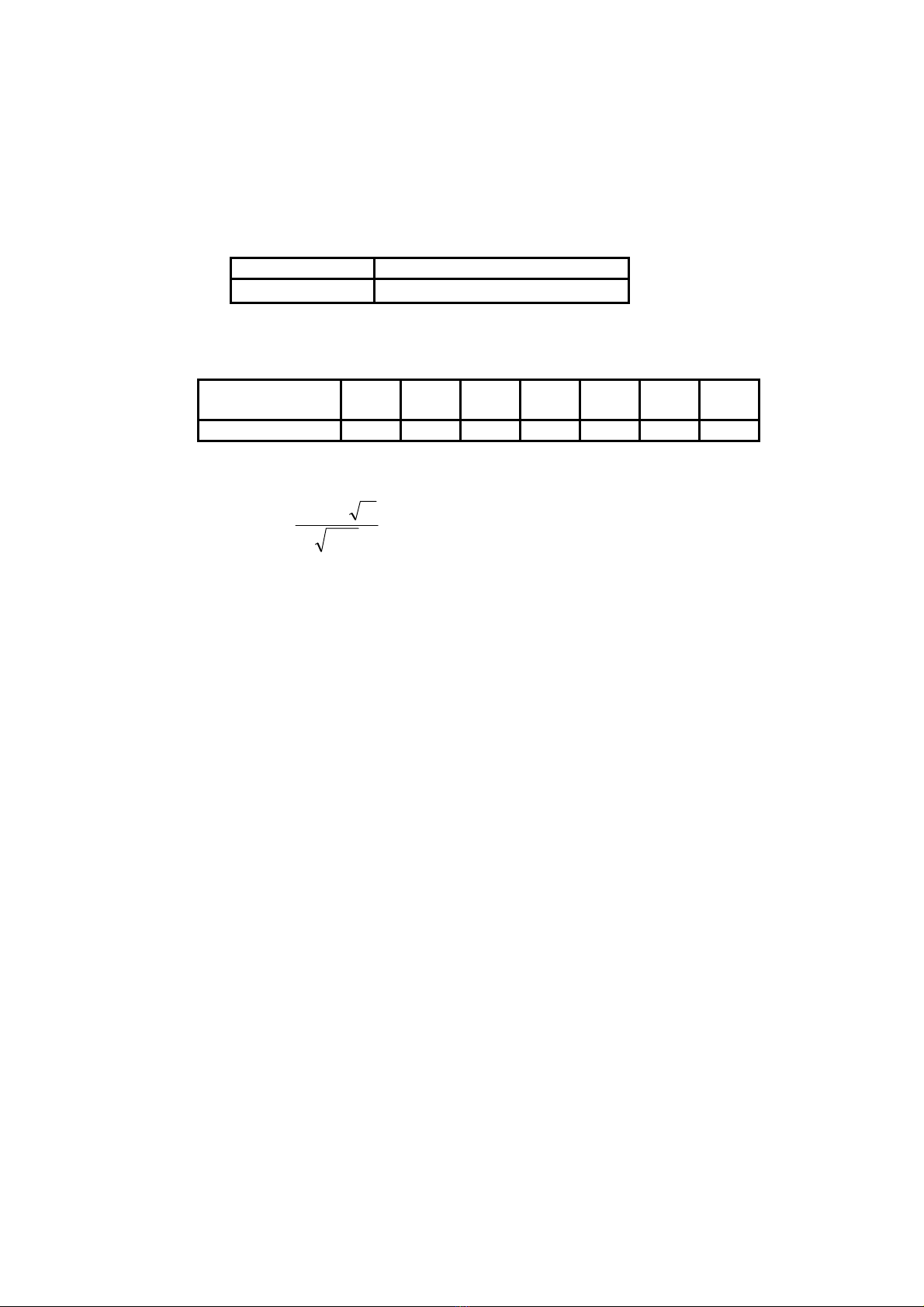

3. Nominal diameter selection··········································································3

4. Dimensions, weight, and structure

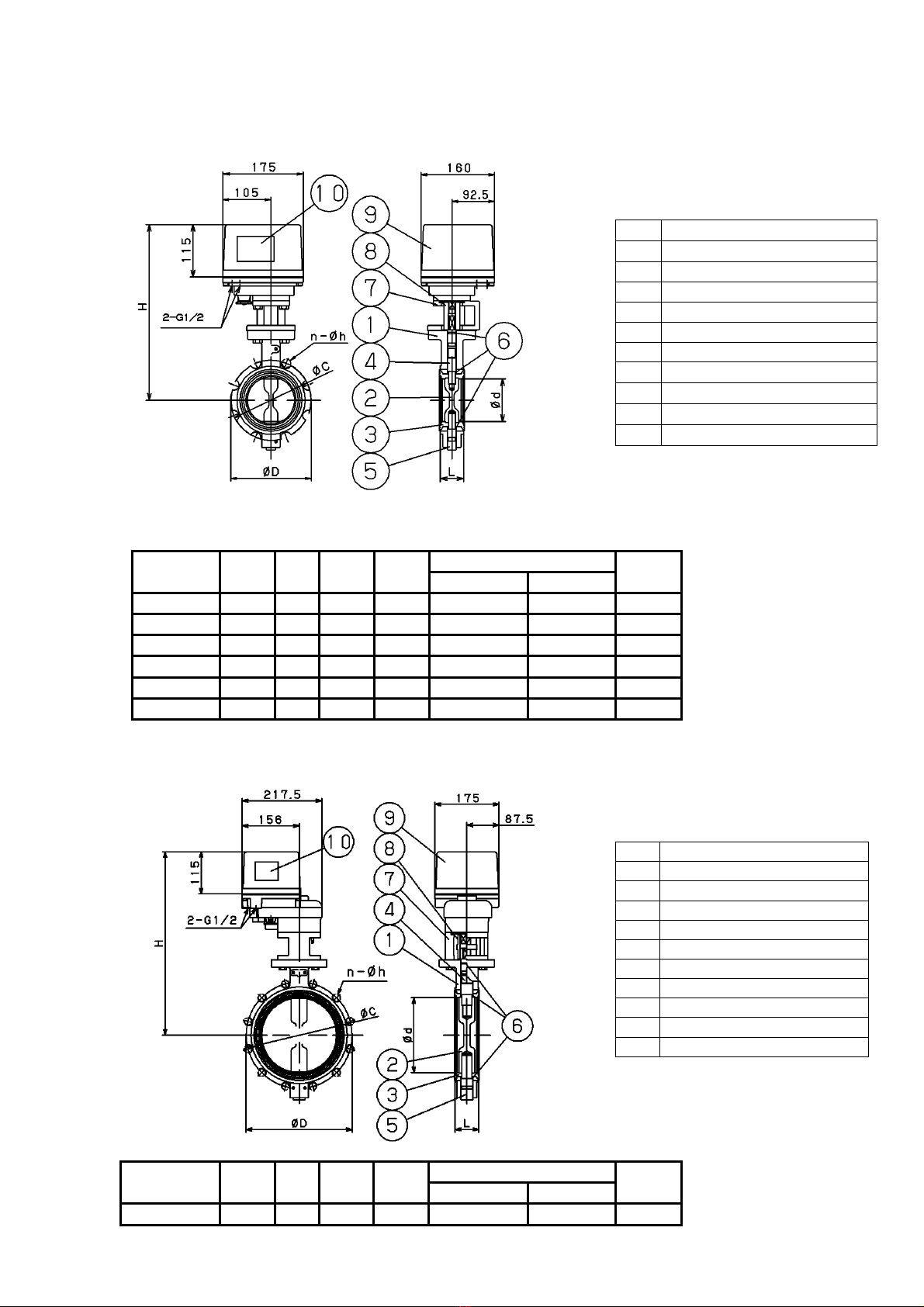

4.1 Emergency shut-off valve ······································································4

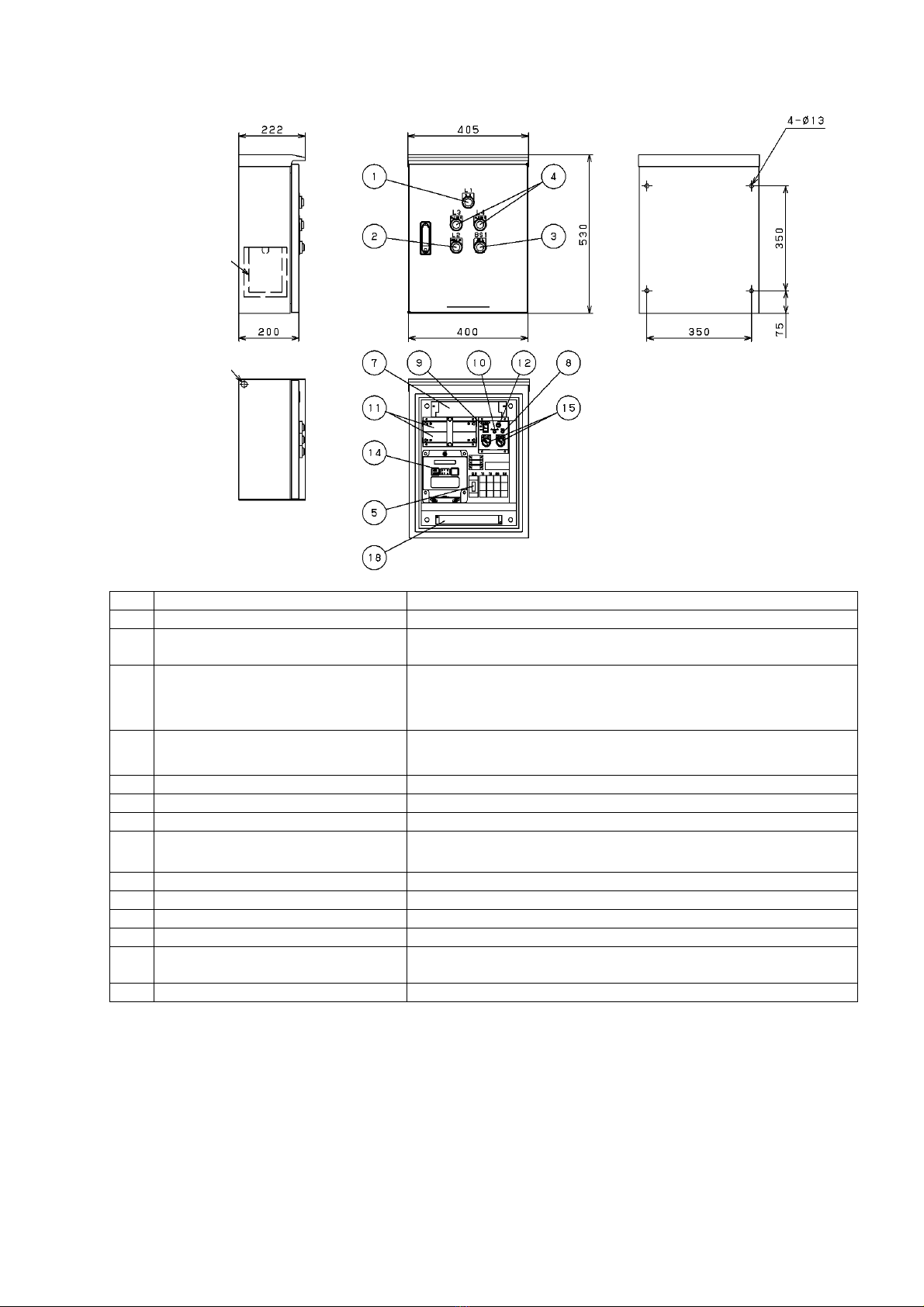

4.2 Emergency shut-off valve control panel ················································5

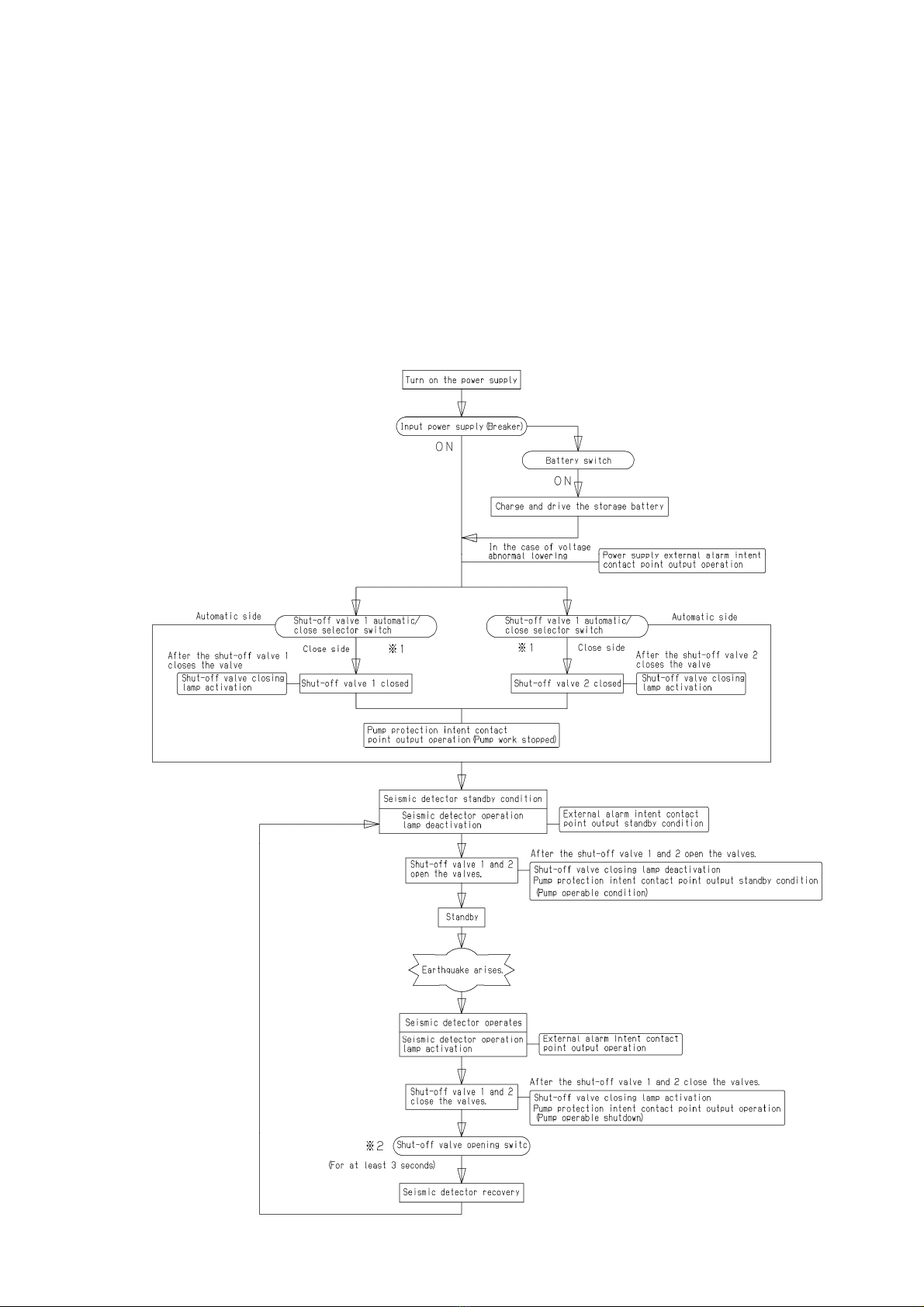

5. Operational description

5.1 Normal condition·····················································································5

5.2 In the case of an earthquake···································································6

5.3 Recovery work························································································6

6. Process flowchart ························································································6

7. Installation procedure

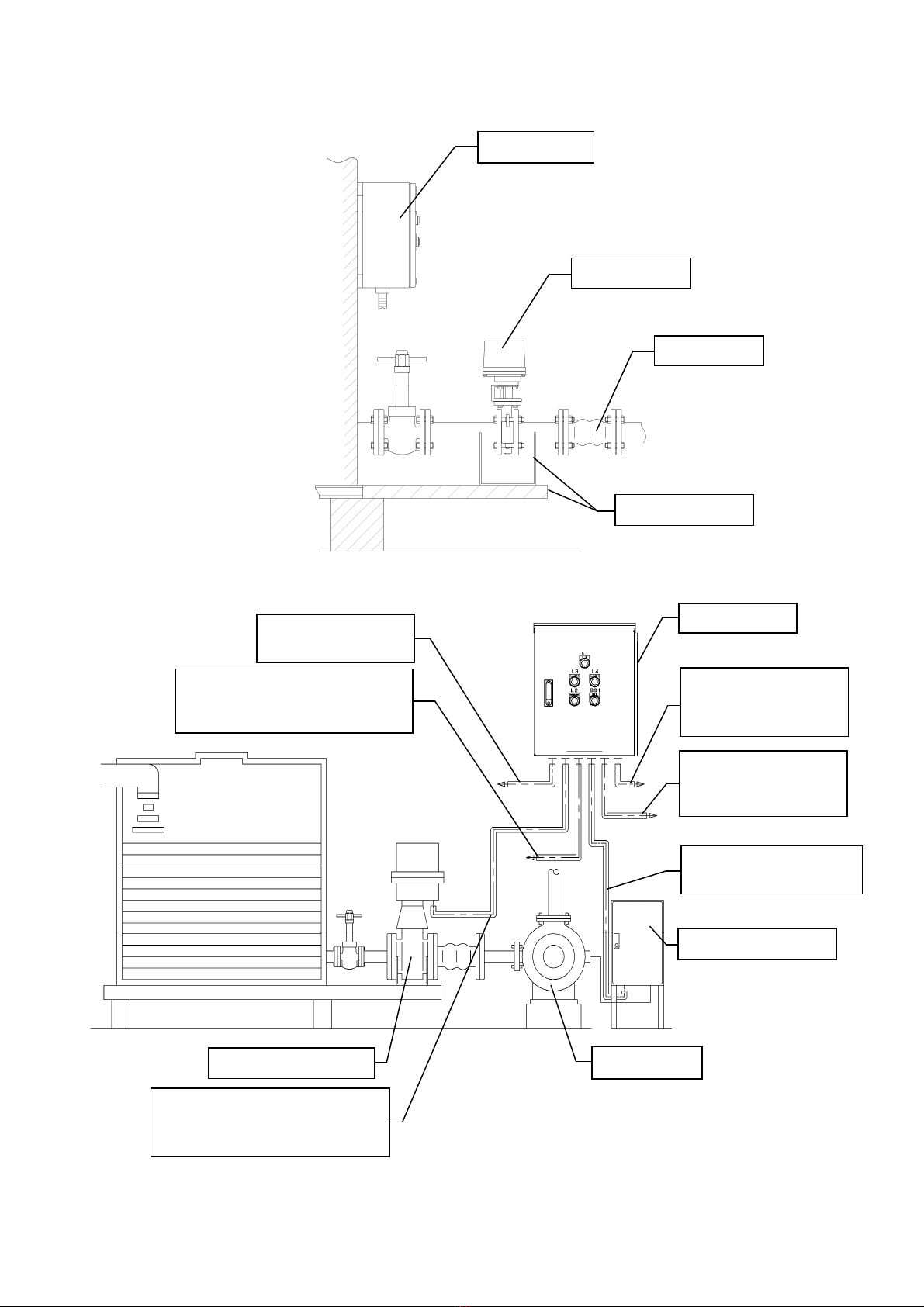

7.1 Sample piping diagram ···········································································7

7.2 Shut-off valve and control panel connection diagram·······················8 to 9

7.3 Warnings and cautions in installing the product ···························10 to 12

7.4 How to adjust the seismic detector ·············································· 12 to 13

8. Operation procedure

8.1 Warnings in operation ········································································· 14

8.2 Trial running··············································································· 14 to 17

9. Maintenance procedure

9.1 Malfunctions and troubleshooting ················································18 to 19

9.2 Warnings and cautions in maintenance and inspection ························19

9.3 Periodic inspection····································································· 19 to 21

9.4 Manual operation method ·························································· 21 to 22

About after-sales service