■EPDT-117b■

MODEL SY-9

STRAINER

PRODUCT MANUAL

.

Thank you very much for choosing the Yoshitake’s product. To ensure the correct and safe use of the

product, please read this manual before use. This manual shall be kept with care for future references.

The symbols used in this manual have the following meanings.

Warning

This symbol indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury.

Caution

This symbol indicates a hazardous situation that, if not avoided, may result in

minor or moderate injury or may result in only property damage.

Table of Contents

1. Features ·································································· 1

2. Specifications···························································· 1

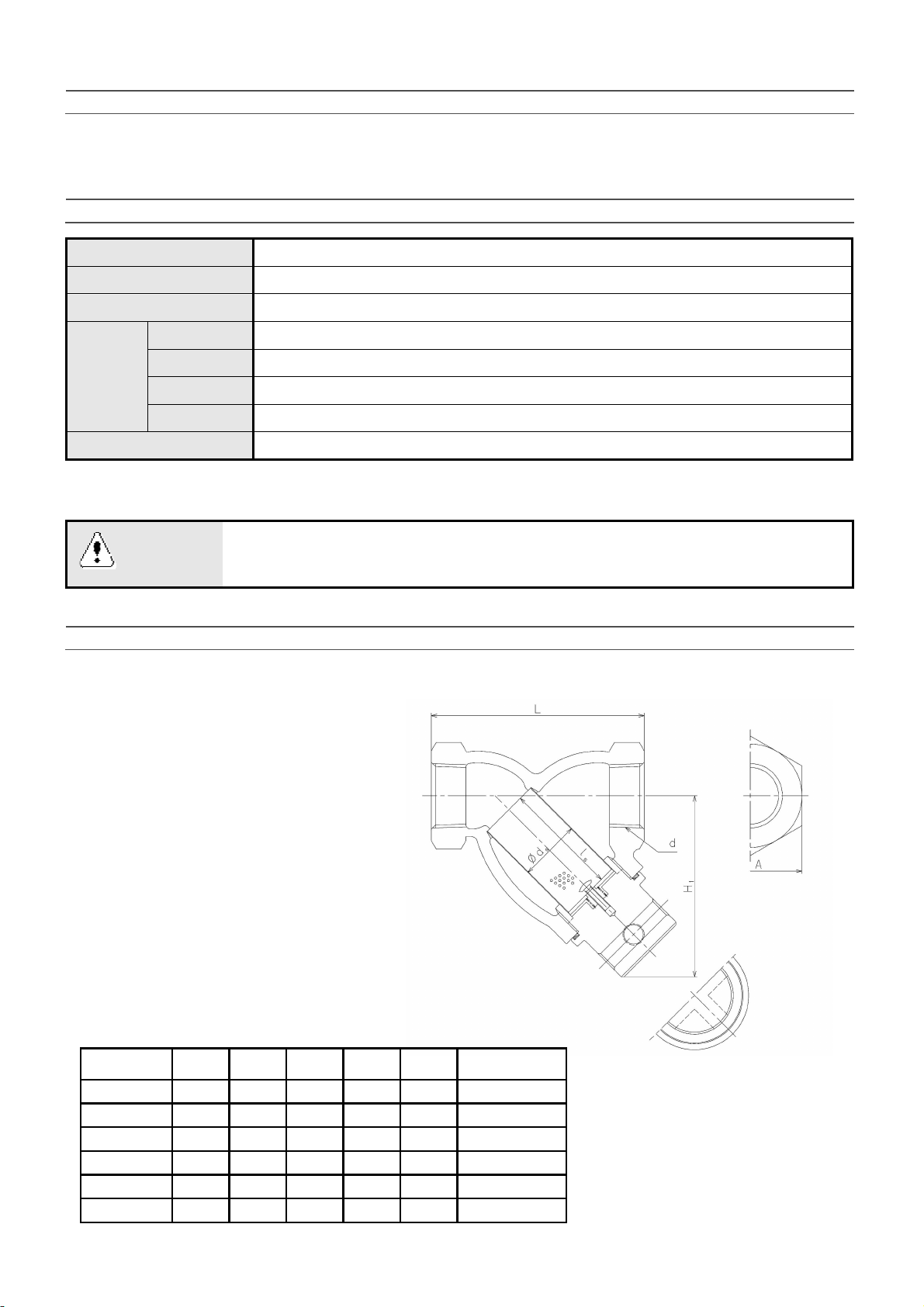

3. Dimensions and Weights············································· 1

4. Operation································································· 2

5. Nominal Size Selection ·············································· 2

5.1 Selection of nominal size······································· 2

5.2 Selection of nominal pipe size································· 2

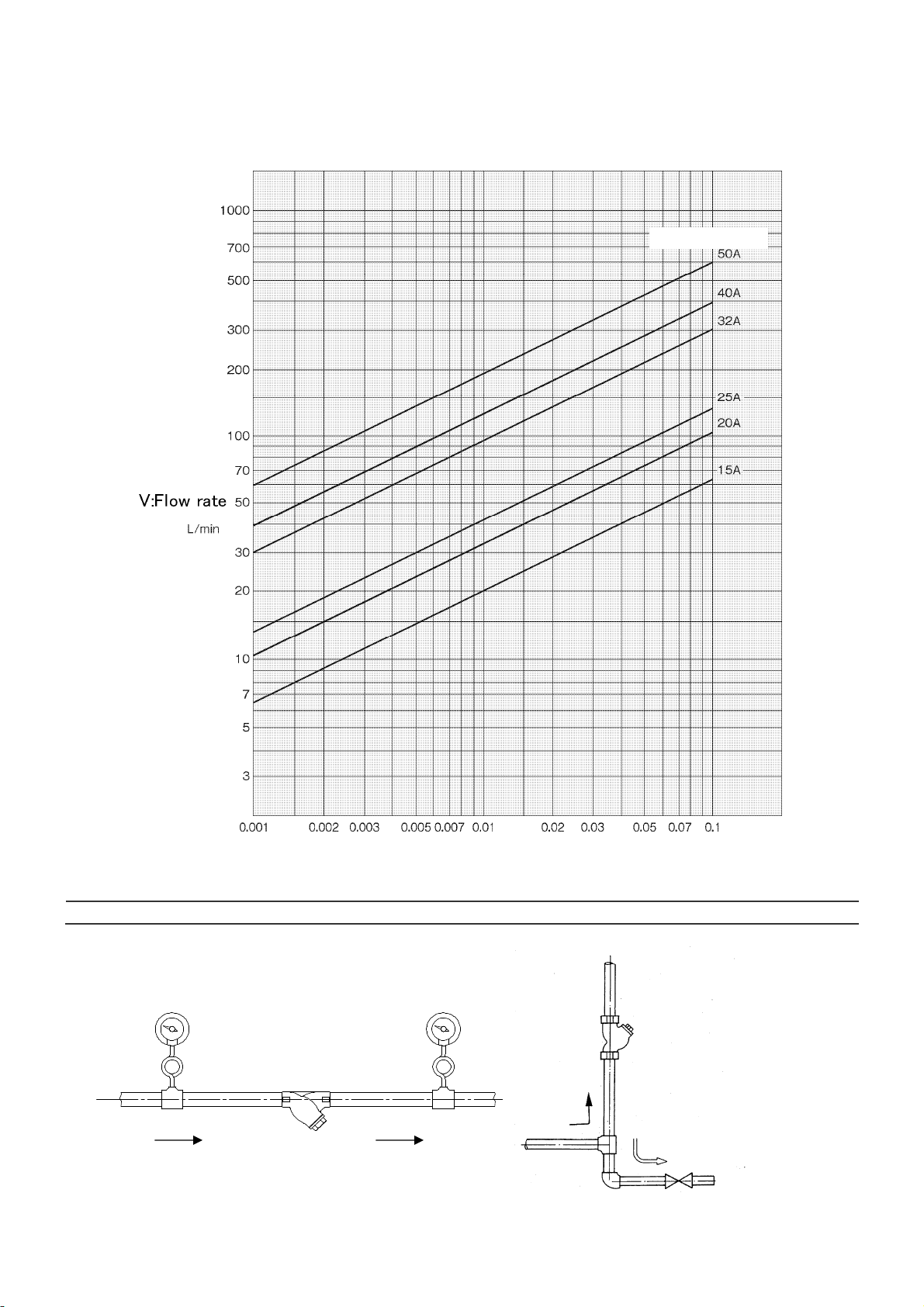

5.3 Nominal size selection chart··································· 3

6. Installation ······························································ 3

6.1 Piping example···················································· 3

6.2 Precautions during installation ································ 4

7. Operating Procedure ················································· 4

7.1 Precautions during operation·································· 4

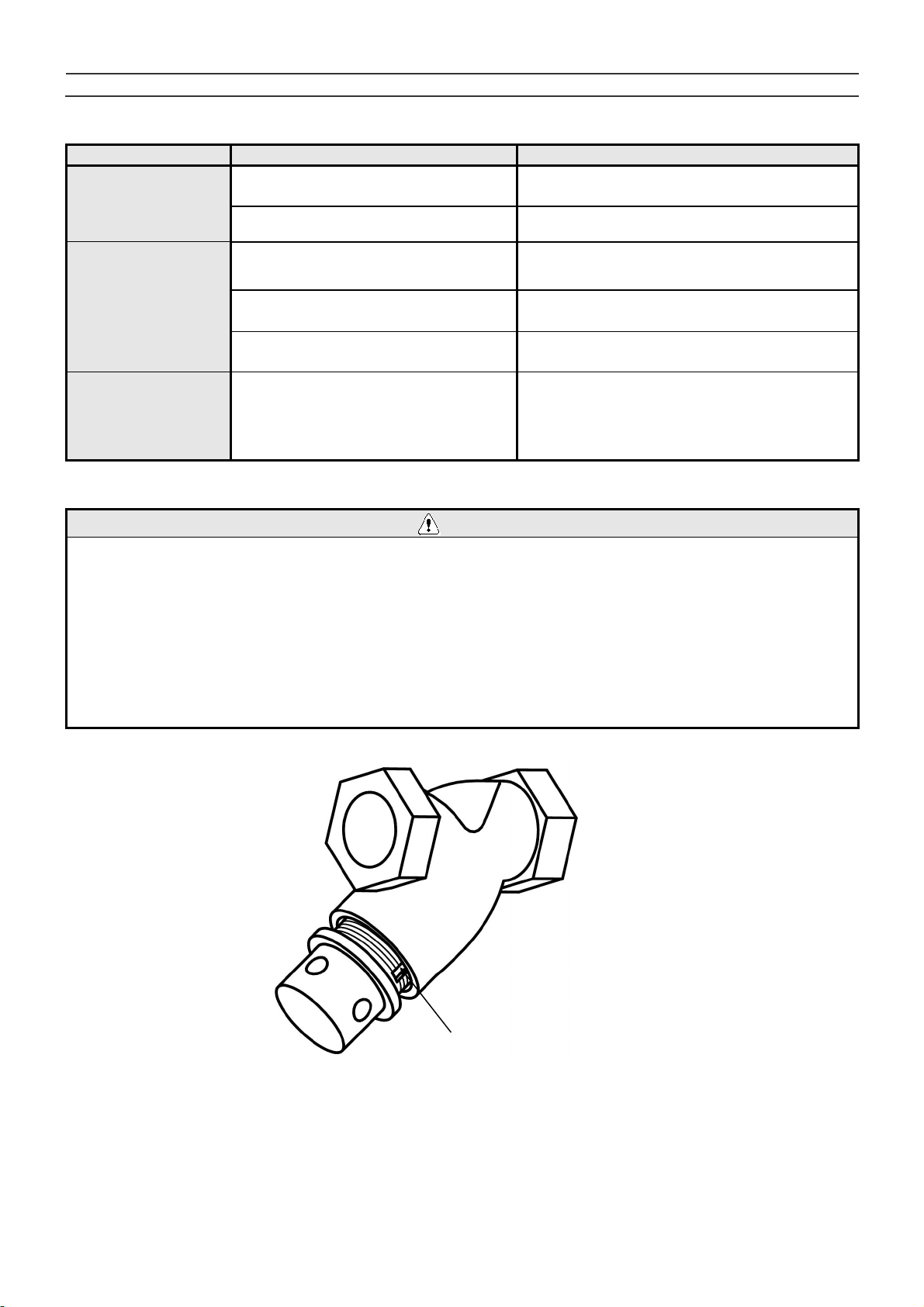

8. Maintenance····························································· 5

8.1 Troubleshooting··················································· 5

8.2 Precautions during maintenance and inspection········· 5

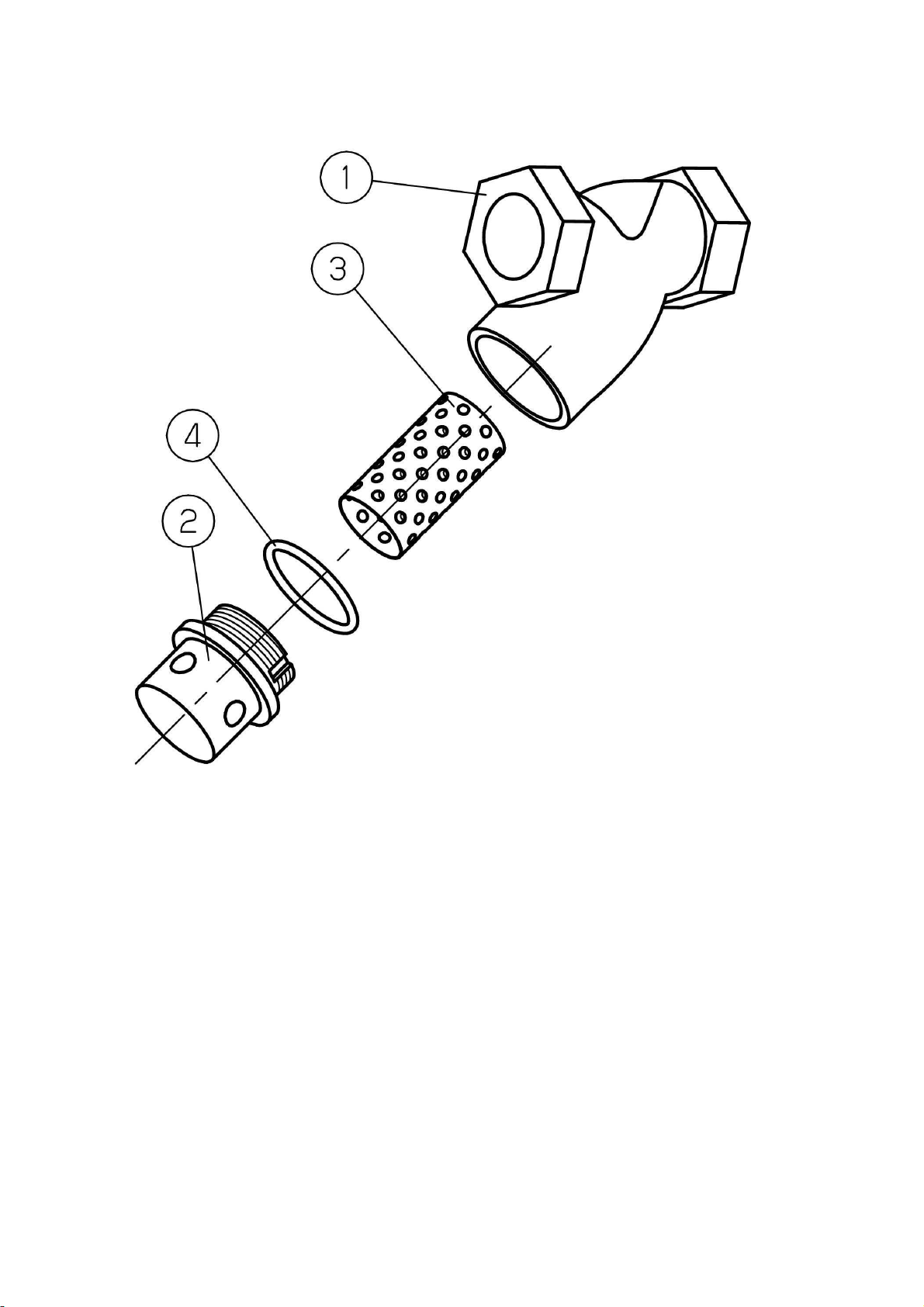

8.3 Disassembly······················································· 6

8.4 Precautions during reassembly······························· 6

8.5 Reassembly························································ 6

8.6 Exploded view····················································· 7

Warranty Information