目 录

SAFETY PRECAUTIONS..................................................................................... 1

1.OVERVIEW.....................................................................................................2

2. WORKING PRINCIPLE................................................................................. 4

2.1 DRIVER............................................................................................4

2.2 ACTUATOR.........................................................................................6

2.3 ANGULAR POSITION SENSOR................................................................ 6

3.MAIN TECHNICAL INDEX............................................................................. 6

3.1 DRIVER............................................................................................6

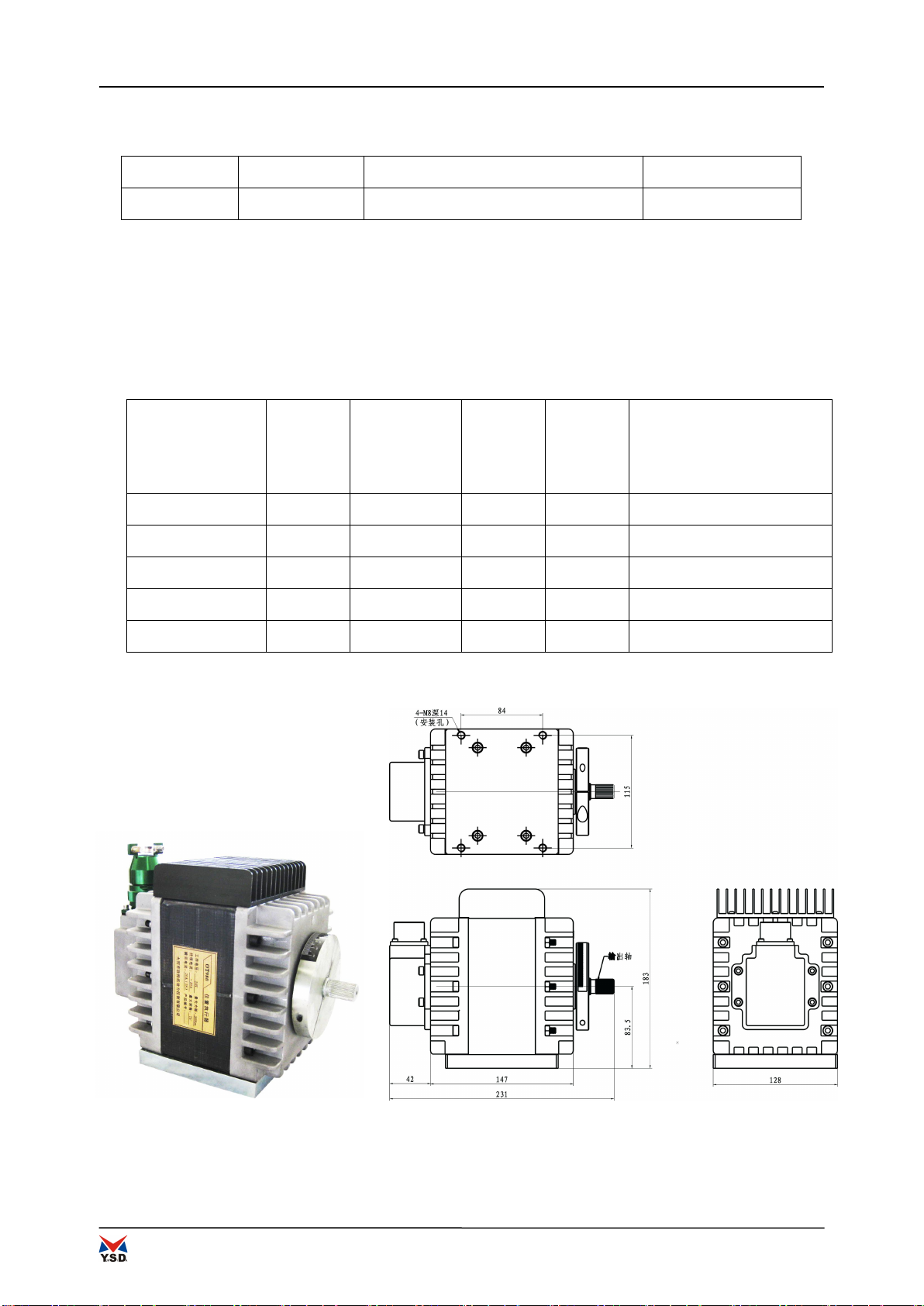

3.2 ACTUATOR.........................................................................................7

4、INSTALL.....................................................................................................7

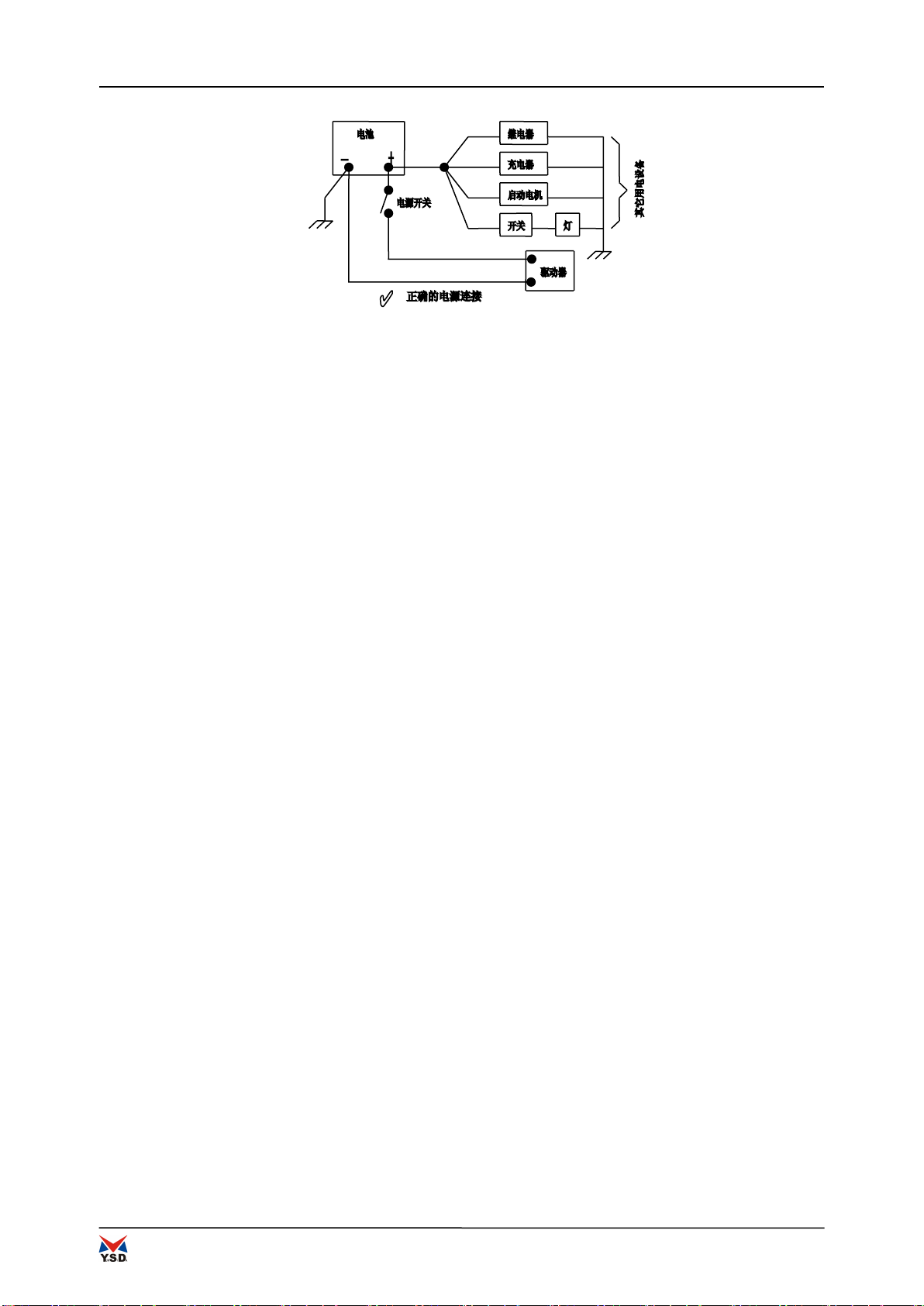

4.1 POWER............................................................................................. 7

4.2 DRIVE INSTALLATION.........................................................................8

4.3 ACTUATOR INSTALLATION....................................................................8

4.4 ACTUATOR MOUNTING BRACKET............................................................. 9

4.5 LINKAGE DEVICE.............................................................................10

4.6 ELECTRICAL CONNECTION.................................................................. 11

4.7 SHIELDING WIRE.............................................................................12

4.8 ADJUSTMENT....................................................................................13

5、COMMON TROUBLESHOOTING GUIDE..........................................................13