ZAMEL Sp. z o.o.

ul. Zielona 27, 43-200 Pszczyna, Poland

tel. +48 32 449 15 00, +48 32 210 46 65, fax +48 (32) 210 80 04

plik: inst_gb_GPRN | modykacja: 31.03.2016 plik: inst_gb_GPRN | modykacja: 31.03.2016

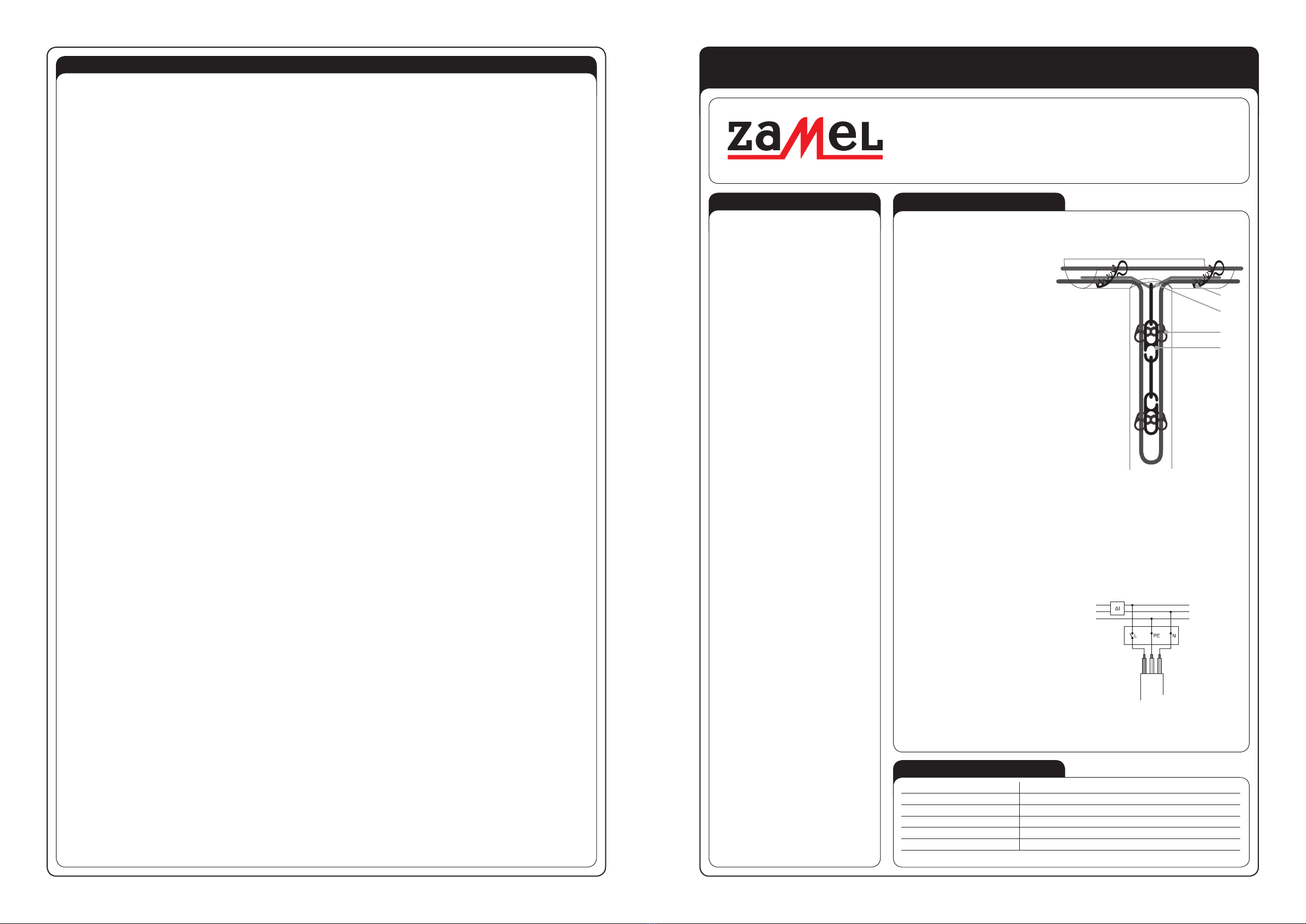

A DRAFT OR A PICTURE OF THE HEATING CABLE, SUPPLY TABLE AND ACCESSORIES

DESCRIPTION

Heating cables type GPRN are used to protect gutters and drain pipes against de-icing. They are

resistant to UV radiation and are laid in gutters in pairs or individually. They are xed by additional

accessories (clips for gutters, clips for drain pipes, suspensions and chains). The cables must be

mounted with a temperature controller, equipped with a temperature sensor or ice and snow sensors.

The arrangement and application of particu-

lar accessories are shown below.

• The GPRN heating cables are designed

to operate outdoor. They are prepared to

operate at 230 V AC nominal voltage and

18 W/m power.

• The heating cable is connected with po-

wer supply cable, which by means of a

temperature controller is connected to

230 V AC.

• The device should be connected accor-

ding to the details included in this ope-

rating manual. Installation, connection

and control should be carried out by a

qualied electrician staff, who act in ac-

cordance with the service manual and the

device functions. Before installation make

sure the connection cables are not under

voltage.

• Improper transport, storage, and use of

the device inuence its wrong functioning.

It is not advisable to install the device in

the following cases: if any device part is

missing or the device is damaged or de-

formed. In case of improper functioning of

the device contact the producer.

GPRN heating cable - set includes:

• one-sided power supply heating cable connected with power supply cable,

• installation instruction with the Warranty Card.

A temperature controller is an essential element used to control the GPRN heating cable. It is used

to connect the heating cable with electric installation. It is important to choose a correct temperature

controller with regard to the application of a heating cable and its function. The ZAMEL Sp. z o.o.

company offers the application of temperature controllers by EBERLE.

It is advisable to choose a temperature control-

ler in accordance to power of the connected

heating cable as well as to the placement of

the heating cable and measurement probes.

To control temperature, a controller keeping a

constant temperature or a controller with a pro-

grammer needs to be used and which allows

for the adjustment of heating parameters.

Depending on the function the heating system

with a temperature controller shall realise, the

following sensors are applied: temperature

sensors, ice and snow sensors, temperature

and humidity sensors.

The connection of the heating cable with

a temperature controller should be done

in accordance with a diagram described

in the temperature controller manual in-

struction.

REMARKS

• During installation it is required to follow in-

structions included in the Heating Cable Ma-

nual Instruction.

• Temperature controller’s installation must be

done according to temperature controller In-

stallation Manual.

• It is forbidden to mount the cable on pins,

bolts, screws or other xing elements that

can damage the outer coating of cables.

• The cable installation surface must be smo-

oth with no sharp edges or sharp xing ele-

ments.

• Heating unit cannot be mounted on non-uni-

form bases.

• Heating cable should not be installed in pla-

ces with permanent building.

• Heating cable resistance should be measu-

red twice: after opening the package and

before installers’ work and also after placing

the heating cable in an appropriate place.

• Ensure the sub-oor is dust and sharp ele-

ments free.

• Don’t install the heating cable if the ambient

temperature is below + 5°C.

• Don’t cut the heating cable or its connection

with power supply cable.

• The heating cable should not undergo exces-

sive strain and should be protected against

sharp device damage.

• Heating unit must be supplied by means of

a device from TN-S electric circuit with RCD

(residual current device) of nominal power

supply lower than 30 mA. The installation

should have surge protection.

• The heating cables must not come into con-

tact, cross with each other or other cables

- this could damage the insulation. The mi-

nimum distance between the heating cables

must not be less than 5-times the diameter.

• It is required to make a draft or add pictures

of arrangement of the heating cable, power

supply cable and the connection place of the

heating cable with power cable („cold wire”).

The draft or pictures are an integral part of

the as-built documentation.

• The non-detachable supply cable cannot be

replaced. If the cord is damaged, the equip-

ment is useless. The power supply cable can

be shortened to the desired length, necessa-

ry for mounting the temperature controller.

• The device is not intended to be used by pe-

ople (children) with limited physical, feeling

or psychic ability or people without experien-

ce or without the device knowledge unless it

is under supervision of a person responsible

for safety or according to installation manual.

• Pay attention to children - they must not play

with the device.

• The radius of heating cable bending shall not

be less than 8 times of its diameter.

• The heating cable cannot be permanently

immersed in any liquid.

• The heating cable must be used in accordan-

ce with manufacturer’s specications.

TECHNICAL DATA

Heating cable TYPE GPRN 12 ÷ 100 m long

Power supply voltage: 230 V AC / 50 Hz

Unit power: 18 W/m

Operating temperature: 80 oC

Supply type: one-sided

Heating cable: two-wire, shielded

The heating cable is ended with H05VV-F 3G1 power supply cable at one side

MATEC – ELECTRIC DE-ICING SYSTEMS MANUAL INSTRUCTION

HEATING DE-ICING CABLE TYPE GPRN FOR GUTTERS AND DRAIN PIPES

230 V AC

RCD

protection device

L(black / brown)

N(blue)

PE (green-yellow )

brown

green-yellow

blue

Temperature

controller

Supply cable

of the one-sided

supplied

heating cable.

Fig. A connection diagram of a heating cable

by means of a temperature controller

to the electrical installation

Fig. Arrangement and application of accessories

KRS-01

ZW-01

KRU-01

LS-01