H. ZANDER GmbH & Co. KG • Am Gut Wolf 15 • 52070 Aachen • Germany

Tel +49 (0)241 9105010 • Fax +49 (0)241 91050138 • info@zander-aachen.de • www.zander-aachen.de 1

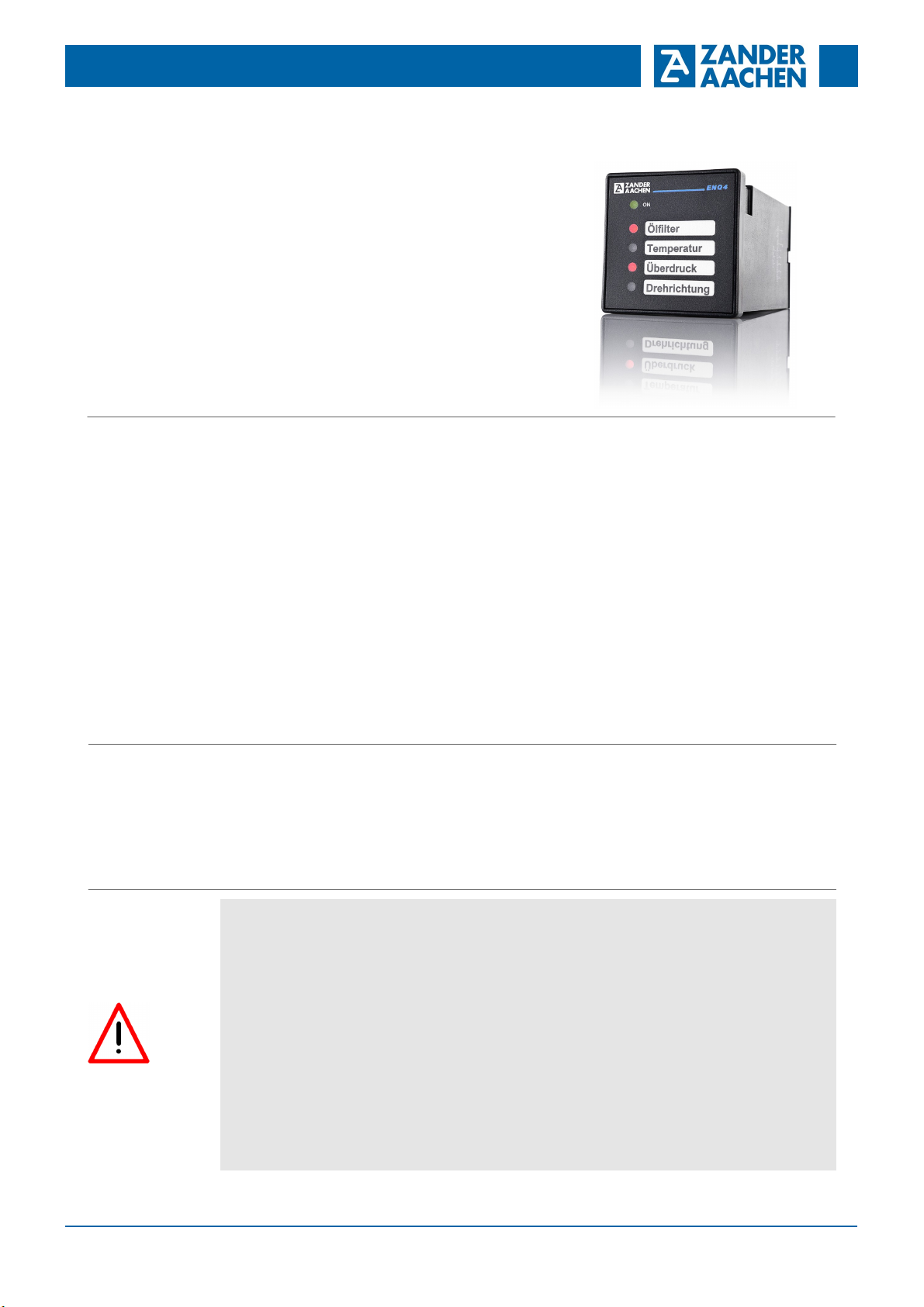

Fault Indicator System ENQ4

L05

E61-283-00

Operating Instructions English translation

Errors and technical changes reserved

Simplify maintenance

Report faults

Avoid damages

Reduce service costs

The ENQ4 offers a complete fault indicator unit for recording

unapproved operating conditions such as excessive pressure

or excessive temperature in a compact design. The devices are

successfully used with compressors, automatic production machi-

nes, vehicles, heating systems and air-conditioners.

The closing of the input S5 activates the opening of the

contact A1-14 without storage function. The contact will

close with the opening of S5 provided that an input S1-S4

do not have a fault report.

Additionally each input is equipped with a signal delay of

about 200 ms for the purpose of filtering out any possible

current interruptions occurring momentarily. Therefore the

switching on of the connected machine by A1-14 and the

simultanous closing of the contacts S1..S4 do not lead to a

fault report.

These measures permit the use of the equipment with un-

shielded input cables up to 100 m in length.

Safety

Precautions

against electrostatic discharge (ESD protection).

Opening the device, any manipulation of the device and

the avoidance of the safety facilities are not permitted.

All relevant safety regulations and standards must be

attended to.

Non-observance of the safety regulations may cause

death, severe injuries or substantial damage to property.

Before use, please, read the operating instructions and

keep it in a safe place. Make sure that the operating

instructions are always available for installation, initial

operation and maintenance.

The installation and operation must be carried out by

qualified personnel only,

who is familiar with the professional handling of machine

equipment,

who is familiar with the valid rules of industrial safety

and accident prevention,

who read and understood the operating instructions and

the system manual.

The safe function of the device during machine operation

cannot be guaranteed in case of wrong connection or

improper operation. This may lead to fatal injuries.

Pay attention to country specific regulations.

The electrical installation must be performed after dis-

connecting the device and the machine from the mains

supply.

The wiring must be carried out according to the instruc-

tions of this operating manual.

The person who programs the device must be protected

Non-observance of the instructions above will cause the

loss of warranty.

Correct Use

Features

Function During normal operation (all external contacts on the inputs

S1..S4 are closed) the internal contact A1-14 is closed.

The alarm contact A1-14 (NC) opens as soon as a fault

alarm input S1..S4 opens. The machine is switched off until

the fault is acknowledged.

Each input channel has a storage function so that faults

occurring even sporadically are recognised. The acknow-

ledgment takes place with the interruption of the power

supply of the ENQ4 system.

There are 4 fault-detection-inputs and one additionel test

input, which operates directly to the output contact of the

unit.

Each fault (input signal-contact open) will be indicated by a

red LED at the front panel, the fault free operation is shown

by a green LED. The report is made through NC-contacts

so that separate cable monitoring is assured.

Various operating/reporting voltages up to AC 230V are

available.

Special function test operation (input S5):

Installation ENQ4 is a panel-mounting device for 45 x 45 mm cutout.

It has a plastic front panel IP54 with identification panel for

the fault messages. A paperstrip for inscriptions is en-

closed at each item. This strip can easily be pushed into

the considered side pocket.

In addition to each fault report display, space for text for

customer specific formatting of the reports is provided. We

will supply the devices with the appropriate text as per your

text documentation for mass production requirements.

All electronic components are integrated in a panel-moun-

ting housing 48 x 48 mm. The front of the device is water

and dust proof. Several modules can be arranged next to

one another in the form of a tableau.

A plastic front frame with external dimensions of 55 x 55 mm

is available as an accessory.