Contents

Table of Contents

Contents .................................................................... 4

Table of Figures ......................................................... 6

GENERAL SATEFY NOTICES........................................ 1

SPECIFIC WARNING AND CAUTION STATEMENTS .... 3

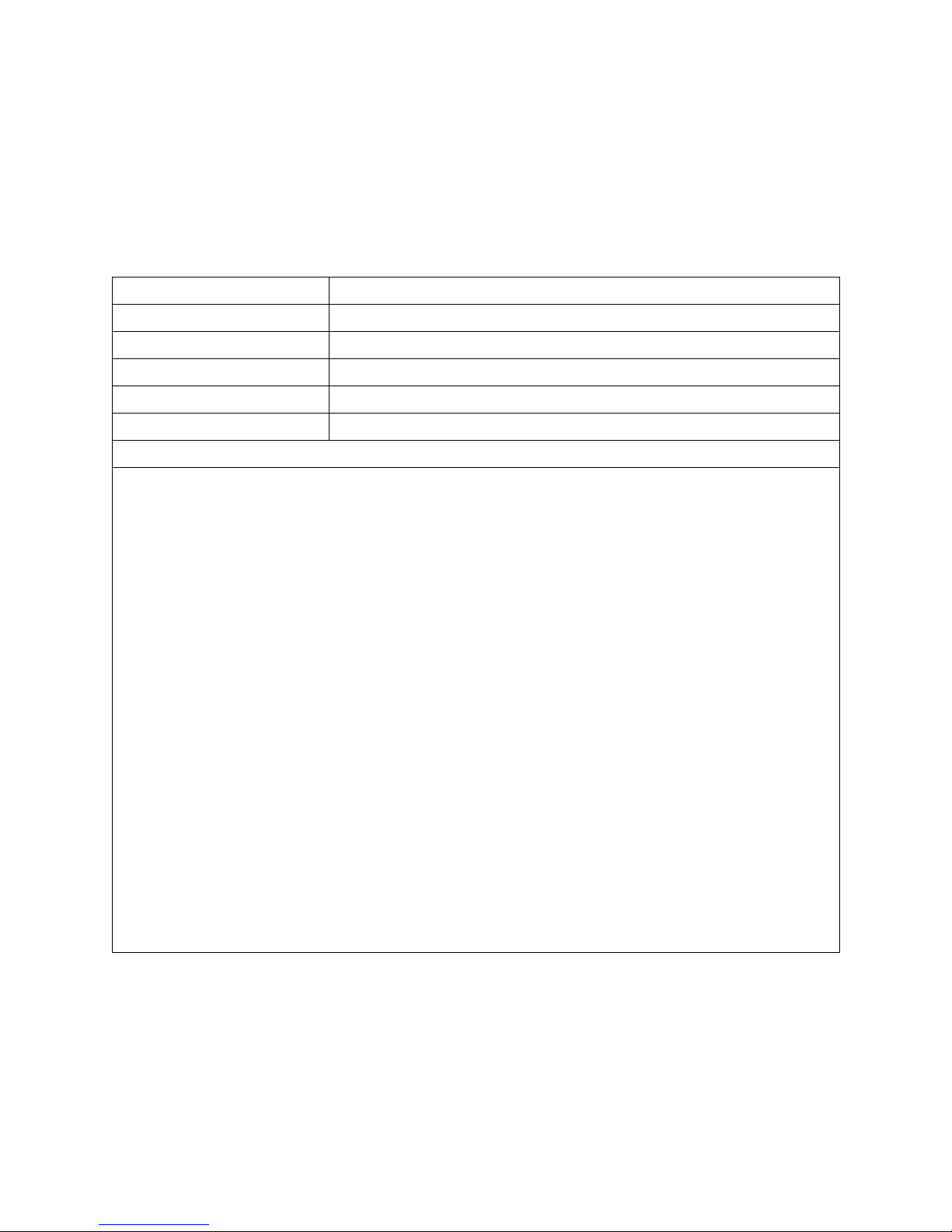

SPECIFICATIONS ........................................................ 5

Z120 MAINTENANCE SCHEDULE ............................... 6

SECTION 1 – Unit Description.................................... 7

1.1 CONDENSING SECTION.................................... 7

1.1.1 Condenser coil.......................................... 7

1.1.2 Filter drier................................................. 7

1.1.3 Compressor .............................................. 7

1.1.4 Receiver.................................................... 7

1.1.5 High-pressure switch................................ 7

1.1.6 CPR valve .................................................. 7

1.1.7 Electric standby operation ....................... 7

1.1.8 DC Motor .................................................. 7

1.1.9 AC Motor .................................................. 7

1.2 EVAPORATOR SECTION ................................... 9

1.2.1 Thermostatic expansion valve.................. 9

1.2.2 Evaporator coil ......................................... 9

1.2.3 Defrost coil ............................................... 9

1.2.4 Evaporator drain tube heaters................. 9

1.2.4 Hot gas solenoid valve.............................. 9

1.3 MICROPROCESSOR ANDCONTROL BOX ........ 10

1.3.1 Microprocessor board ............................ 10

1.3.2 Control box............................................. 11

SECTION 2 – Unit Identification............................... 12

2.1 DECIPHERING THE MODEL CODE .................. 12

2.2 DECIPHERING THE SERIAL NUMBER.............. 13

SECTION 3 - Operation ............................................ 14

3.1 SAFETY DEVICES............................................. 14

3.2 REFRIGERATION CIRCUIT............................... 14

3.2.1 Cooling.................................................... 14

3.2.2 Null ......................................................... 15

3.2.3 Defrost and Heat.....................................16

3.2.4 Refrigeration Symbol Table.....................17

3.2.5 Defrost system ........................................18

3.2.6 Manual defrost........................................18

3.2.7 Defrost relay............................................18

3.2.8 Defrost solenoid valve (Hot Gas Solenoid Valve)

.........................................................................18

3.2.9 Condenser Inlet valve..............................18

3.3 CONTROL SYSTEM..........................................19

3.3.1 Description ..............................................19

3.3.2 Microprocessor module (CPU Board) .....19

3.3.3 In-cab controller...............................19

3.4 START UP........................................................21

3.4.1 Starting.............................................21

3.4.3 Weekly Pre-trip Inspection .....................21

3.4.4 After Start Inspection..............................22

3.4.5 Loading Procedure ..................................22

3.4.6 Post Load Procedure ...............................22

3.4.7 Weekly Post Trip Checks .........................22

3.5 ALARM MANAGEMENT..................................22

3.5.1 Accessing alarm messages ......................22

3.5.2 Reset alarms............................................22

3.5.3Alarms list ................................................23

3.6 MICROPROCESSOR PARAMETERS..................24

3.6.1 To enter a Set Point ................................24

3.6.2 Parameter programming ........................24

3.6.3 Common Parameters ..............................24

3.6.4 Service Alarm Management....................26

SECTION 4-System Maintenance .............................27

4.1 GENERAL CATEGORIES...................................27

4.1.1 Electrical..................................................27

4.1.2 Refrigeration ...........................................27

4.1.3 Structural ................................................27

4.2 INSTALLING THE MANIFOLD GAUGE SET.......27

4.2.1 Manifold Gauge Components.................28

4.2.2 Preparing Manifold Gauges for use ........28

4.2.3 Connecting Manifold Gauges..................28