Voltage Problems (continued)

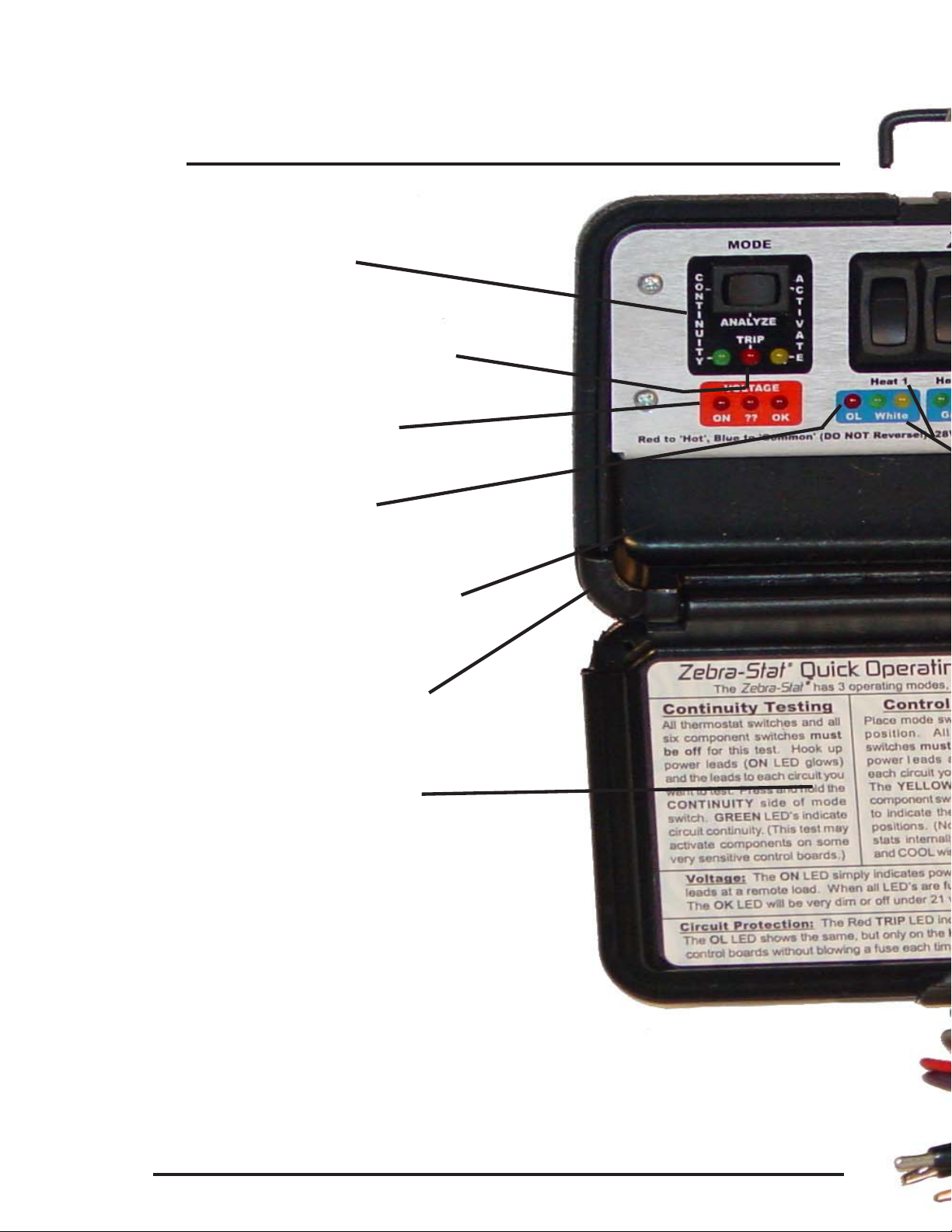

There are 3 red LED’s in the voltage section:

ON, ??, and OK. The ON LED will light when

thevoltageapplied tothe powerinputleads is

at least 8 volts. The ?? (Questionable) LED

glows about half-brightness at 19.5 volts, and

full-brightness at 20.5 volts. The OK LED

glows about half-brightness at 21.5 volts, and

is fully bright at 23 volts.

Any time that you are using the ZebraStat

and notice that the OK LED isn’t fully lit, you

may want to check the voltage level at the

component that is farthest away from the sys-

tem transformer while under load. (The volt-

agedropfromthewireswillbegreatestthere.)

IftheOK LEDisn’tglowingatleasthalf-bright-

ness, there is the potential that higher tem-

peratures (higher wire resistance) and lower

line voltage (due to high demand) may cause

that component to not be able to close fully,

or, in the case of a reversing valve, not be

abletochangepositions. Ahigher-ratedtrans-

former may be called for, or larger wiring.

9