Safety

General safety instructions

WARNING: Read the warning instructions

that follow before you use the product.

• A chainsaw is a dangerous tool if used carelessly or

incorrectly and can cause serious injury or death. It

is very important that you read and understand the

contents of this operator’s manual.

•Under no circumstances may the design of the

product be modified without the permission of the

manufacturer. Do not use a product that appears to

have been modified by others and always use

original accessories. Non-authorized modifications

and/or accessories can result in serious personal

injury or the death of the operator or others.

• The inside of the muffler contain chemicals that may

be carcinogenic. Avoid contact with these elements

in the event of a damaged muffler.

• Long term inhalation of the engine’s exhaust fumes,

chain oil mist and dust from sawdust can represent a

health risk.

• This product produces an electromagnetic field

during operation. This field may under some

circumstances interfere with active or passive

medical implants. To reduce the risk of serious or

fatal injury, we recommend persons with medical

implants to consult their physician and the medical

implant manufacturer before operating this product.

• The information in this operator's manual is never a

substitute for professional skills and experience. If

you get into a situation where you feel unsafe, stop

and seek expert advice. Contact your servicing

dealer or an experienced chainsaw user. Do not

attempt any task that you feel unsure of!

Safety instructions for operation

WARNING: Read the warning instructions

that follow before you use the product.

• Before using a chainsaw you must understand the

effects of kickback and how to avoid them. See

instructions under the heading

What is kickback? on

page 17

.

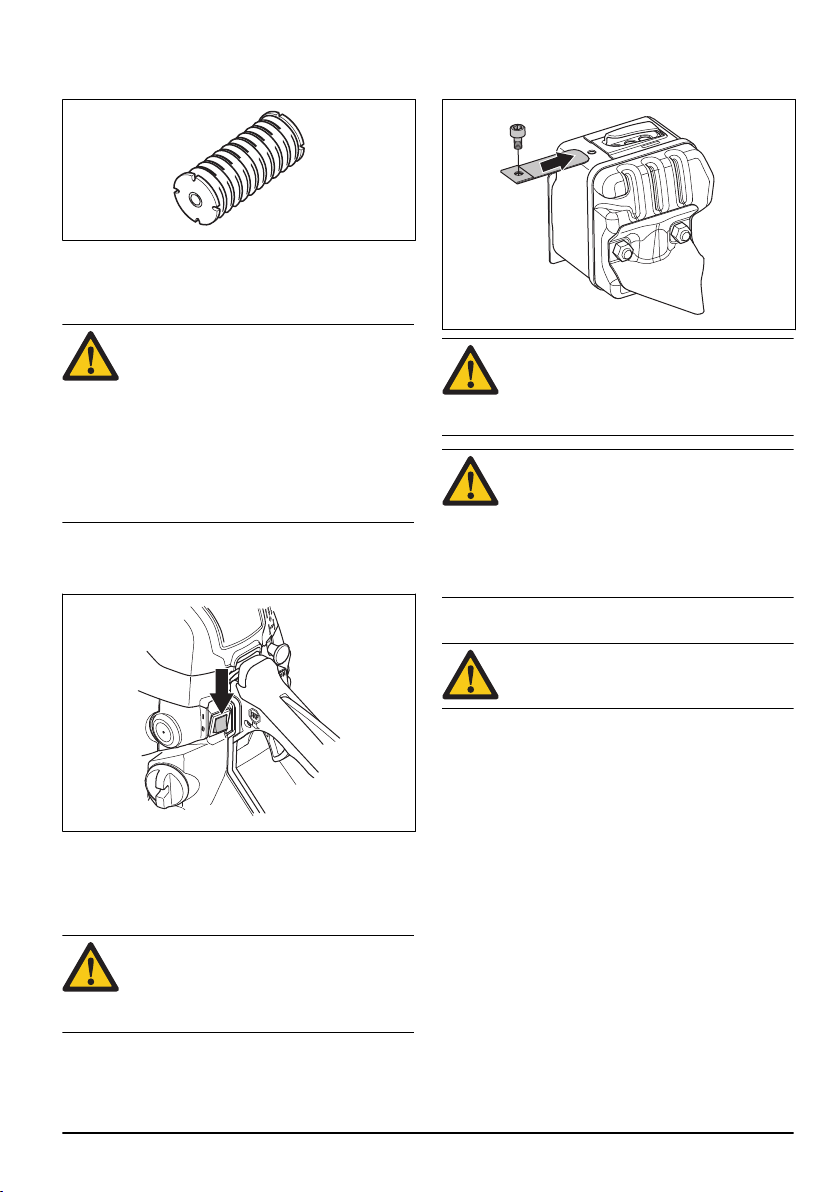

• Never use a product that is faulty. Carry out the

safety checks, maintenance and service instructions

described in this manual. Some maintenance and

service measures must be carried out by trained and

qualified specialists. See instructions under

Maintenance on page 25

• Never use a product with visible damage to the

spark plug guard and ignition cable. A risk of

sparking arises, which can cause a fire.

• Never use the product if you are fatigued, while

under the influence of alcohol or drugs, medication

or anything that could affect your vision, alertness,

coordination or judgement.

•Do not use the product in bad weather such as

dense fog, heavy rain, strong wind, intense cold,

etcetera. Working in bad weather is tiring and often

brings added risks, such as icy ground,

unpredictable felling direction, etcetera.

• Faulty cutting equipment or the wrong combination

of guide bar and saw chain increases the risk of

kickback! Only use the guide bar and saw chain

combinations we recommend, and follow the filing

instructions. See instructions under

Accessories on

page 40

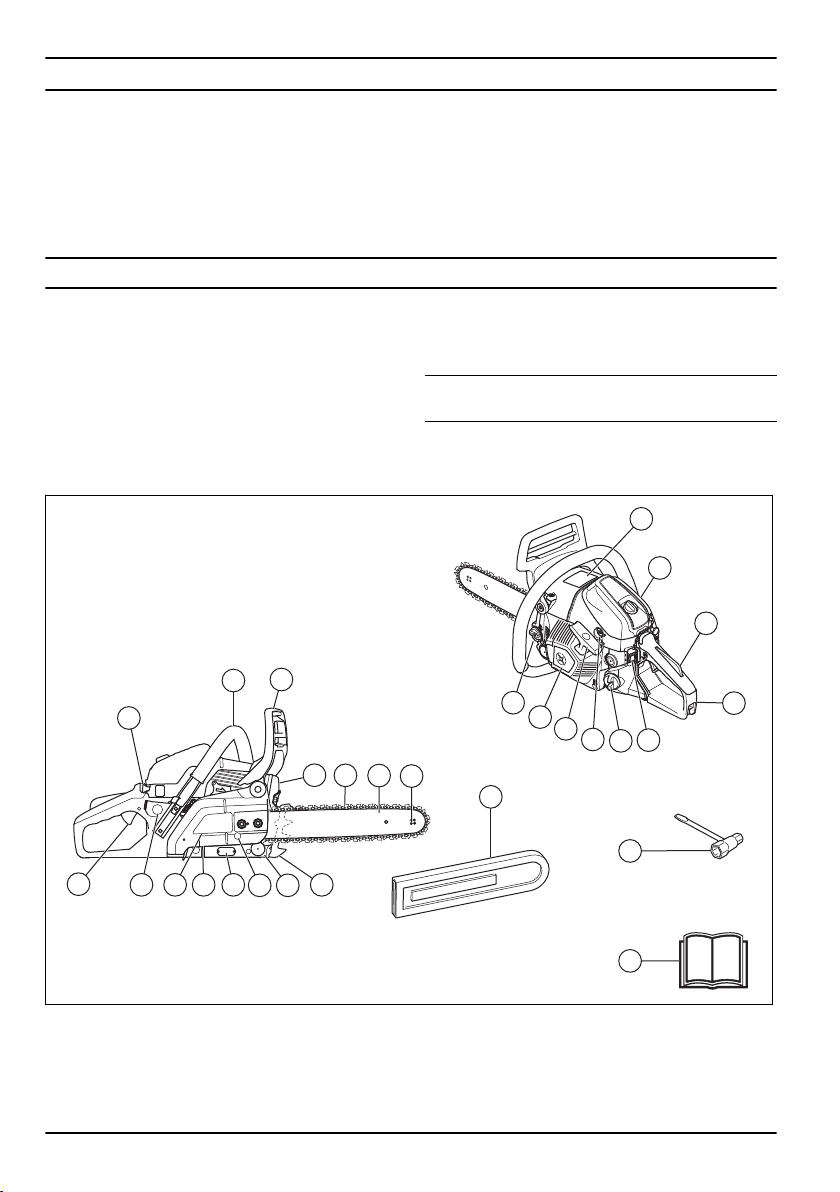

• Never start a chainsaw unless the bar, saw chain

and all covers are fitted correctly. See instructions

under the heading

Assembly on page 12

. Without a

bar and saw chain attached to the chainsaw the

clutch can come loose and cause serious injury.

• Do not drop start. This method is very dangerous

because you may lose control of the chainsaw.

• Never start the product indoors. Exhaust fumes can

be dangerous if inhaled.

•Observe your surroundings and make sure that there

is no risk of people or animals coming in contact with

or affect your control of the product.

4320 - 005 - 27.09.2017