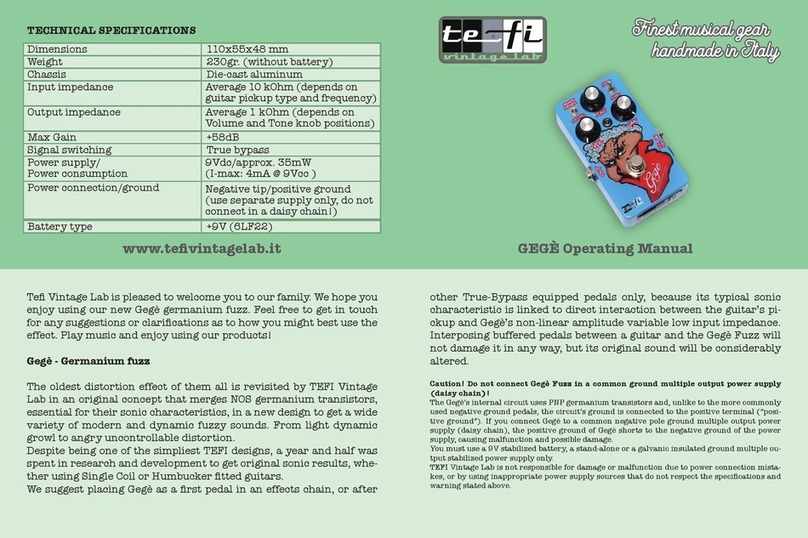

7

Table 1: Quaverato Harmonic Tremolo Pedal Bill of Materials

Part # Description Notes Qty

CB-06-30 Hookup Wire, 2" (5cm) x 5 wires 1

CB-90-13 Heat Shrink Tube, 3/16" x 1-1/2" (5x40mm) For Optocouplers 1

CD-10-12 Insulation Cardstock, 3/4" x 8" (2x20cm) 1

CH-10-30 Steel Chassis, Top & Bottom 2

CP-10-03 Electrolytic Cap, Radial 5x11mm 1uF C4 1

CP-10-08 Electrolytic Capacitor 220uF C14 1

CP-11-10 Electrolytic Cap, Radial 5x11mm 10uF C15 1

CP-20-07 Film Capacitor 22nF C2, C3 2

CP-20-16 Film Capacitor 1uF C1 1

CP-30-18 Ceramic Capacitor 1uF C7 - C13,C16 8

CP-30-19 Ceramic Capacitor 22pF C5, C6 2

CR-10-10 Crystal Oscillator 16MHz Y1 1

DI-20-01 Diode General Purpose 1N4007 1000V 1A D1, D2, D3 3

DI-30-32 LED, 3mm Green TAP LED 1

DI-30-36 LED, 3mm Red BYPASS LED, POWER LED 2

DI-30-52 LED, 5mm Green For Optocouplers 2

FA-60-32 Screw, Philips Pan Head #6 x 1/4” 4

HD-32-04 Knob 7

HD-40-01 ¼" TRS Audio Jack J1, J2 2

HD-40-10 DC Power Jack P1 1

HD-50-02 Grounding Solder Lug 1

HE-20-01 Header, Single Row, 10 Pins P2, MIDI IN 1

HE-25-28 Socket, 28 Pin U1 1

IC-22-20 J-FET Dual Op Amp, TL072 U2, U3 2

IC-26-39 Transistor, 2N3904 Q1, Q2 2

IC-30-60 Microcontroller, ATmega328-PU U1 1

IC-80-52 Voltage Regulator, 78L05 U5 1

PC-10-01 Quaverato PCB 1

PL-10-10 Quaverato Faceplate Sticker 1

PL-10-90 Serial Number Sticker 1

PT-10-26 Potentiometer, 16mm 100K VR2, VR3, VR4, VR5, VR6, VR7 6

PT-10-27 Potentiometer, 16mm 500K VR1 1

PT-30-10 Trim Pot, 10K VR8, VR9 2

PT-30-30 Trim Pot, 100K VR10 1

RL-30-01 Relay, HFD2-005-S-L2 RL1 1