8

POPULATING THE PRINTED CIRCUIT BOARD

Your work space should be well-lit, well-ventilated, and disposable; that

is, don’t work on the nice dining room table! Work on a utility surface

that you can burn, drill, and scratch. A piece of ¼” tempered masonite,

or a chunk of MDF, makes an excellent surface if you don’t have a

utility work bench.

CAUTION: Solder fumes are not healthy for you. The fumes consist

of vaporized flux, which might irritate your nose and lungs. You should

work in a space where the air drifts away from you as you work, so fumes do

not rise straight into your face.

CAUTION: Solder residue usually contains lead, which is poisonous if you ingest it. Do not breathe

the fumes, do not eat the supplies, wash your hands after you handle solder, and sweep and wipe up

your work space after EVERY USE.

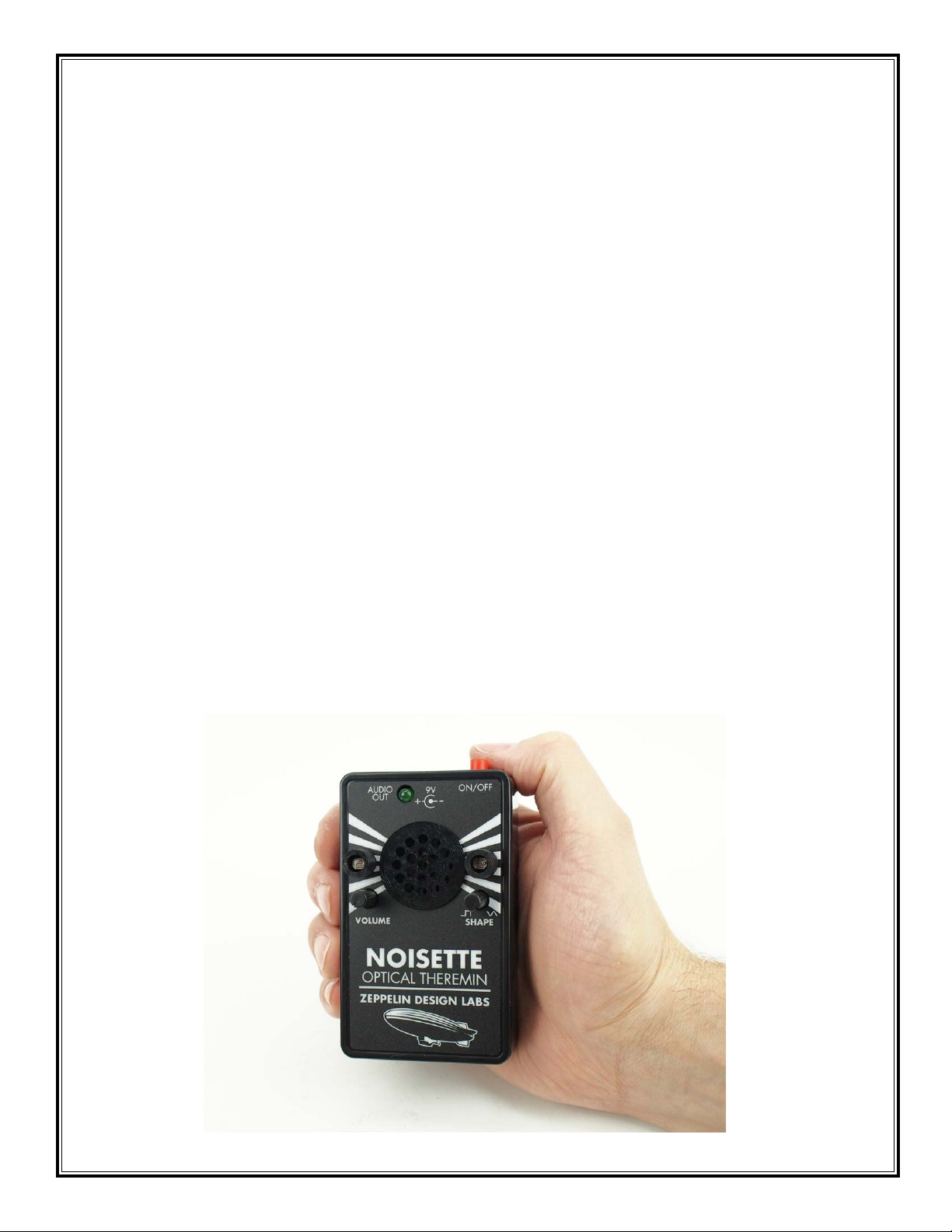

Your Noisette Optical Theremin contains one printed circuit board (PCB). All of the components will be

installed on the component side of the board, which is the side that has the part labels on it. The other

side of the board is called the solder side, which, as the name implies, is the side on which the legs

of the components are soldered. Proper technique for installing and soldering components to a circuit

board is demonstrated through several great resources on Instructables and Youtube under the search

“PCB soldering tutorial.”

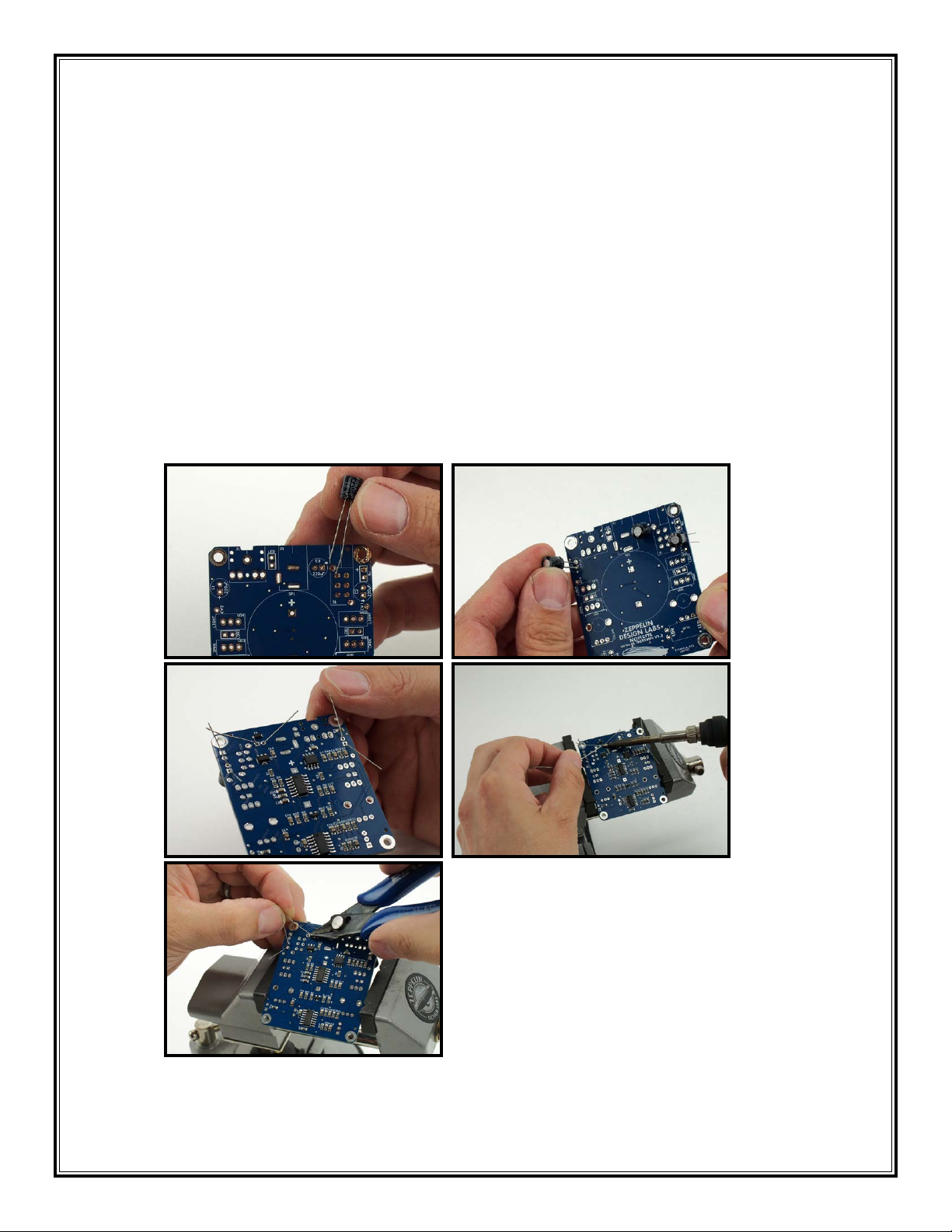

The general procedure consists of the following:

1. Install the part on the component side of the board, by threading the wire leads through the

appropriate holes in the board. For your convenience, the board has silk screen outlines indicating

where the components should be placed, along with text indicating the part number and the component

value.

2. Hold the component in place with your finger and turn the board over.

3. Gently bend the leads out at about 45 degrees to keep the component from falling out of its holes.

4. Install all of one type of component, bending each of the leads as they are installed.

CB-90-15 HD-05-01 ST-10-05 FA-60-38 FA-60-37

HE-60-02 SW-60-22

TIP: Empty the parts

of the kit into a bowl, NOT

onto the cluttered workbench, or

onto the living room carpet! This

will protect you from losing tiny

parts.