4

• Sharp pencil

• 12” Ruler

• Bar clamps, minimum 12” opening, two of them

• Utility knife or X-Acto knife or scissors

• Heat gun, or very hot hair dryer

• Soldering Iron, good quality, 15-50 watt

• Wet sponge or dry solder-cleaning pad

• Wire stripper / cutter, to strip 16-gauge wire

• Needle-nose pliers

• Some sort of clamp or fixture to hold parts while soldering. Your bar clamp might work.

2. Supplies

• Solder, rosin core for electronics

• Good quality wood glue such as TiteBond II or III

• Masking tape

• Good quality wood filler such as DAP Plastic Wood (optional)

• Sandpaper, either discs for your orbital, or sheets for your block: 60, 120, 220, 320

• Very small can of MinWax Dark Walnut Wood Finish (oil-based stain) or equal

• Small can of MinWax Wipe-On Poly, clear satin, or equal

• A small amount of flat black paint, spray or can

• Mineral spirits, for cleanup

• Clean rags

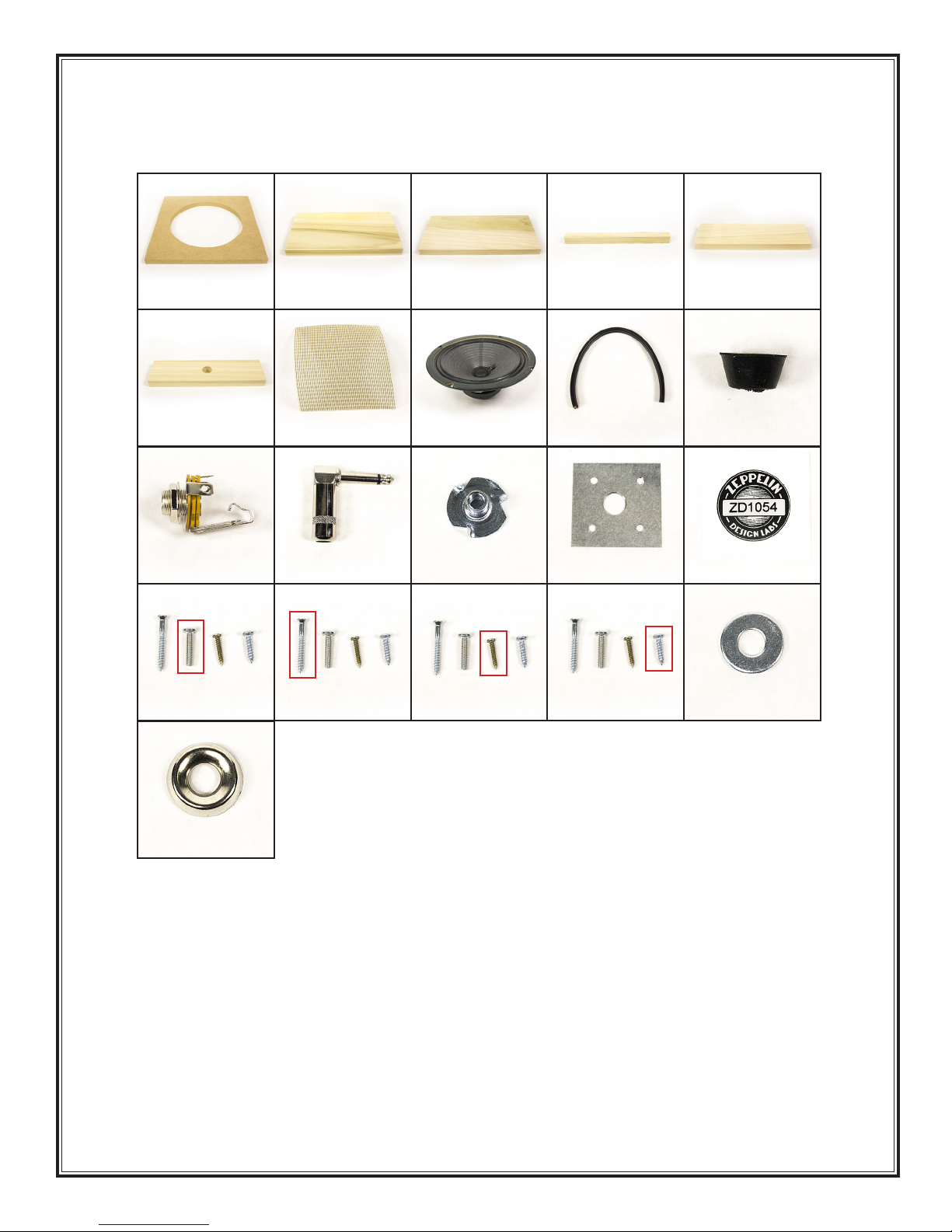

WHAT’S IN THE BOX

Table 1 on Page 6 shows a complete parts list of everything that

should be present in your kit, followed by nice color pictures

of each part. Print the parts list and carefully go through the

kit, identifying every part. Besides verifying that nothing is

missing, this will acquaint you with the parts and their names.

If ANYTHING is missing, or damaged beyond use, first double-

check: we double-checked before sealing the box at our lab! If it’s

still missing, EMAIL US right away at support@zeppelindesignlabs.

com. Include your serial number (on a little round sticker in the bag of hardware). If we are reasonably

convinced that we goofed and shorted your kit, we will get replacement parts in the mail ASAP. If you

lose or damage anything, we will be glad to sell you replacements. The unusual or custom components

can be ordered from us direct. For more common parts, like screws, you should just go to a local

hardware store.

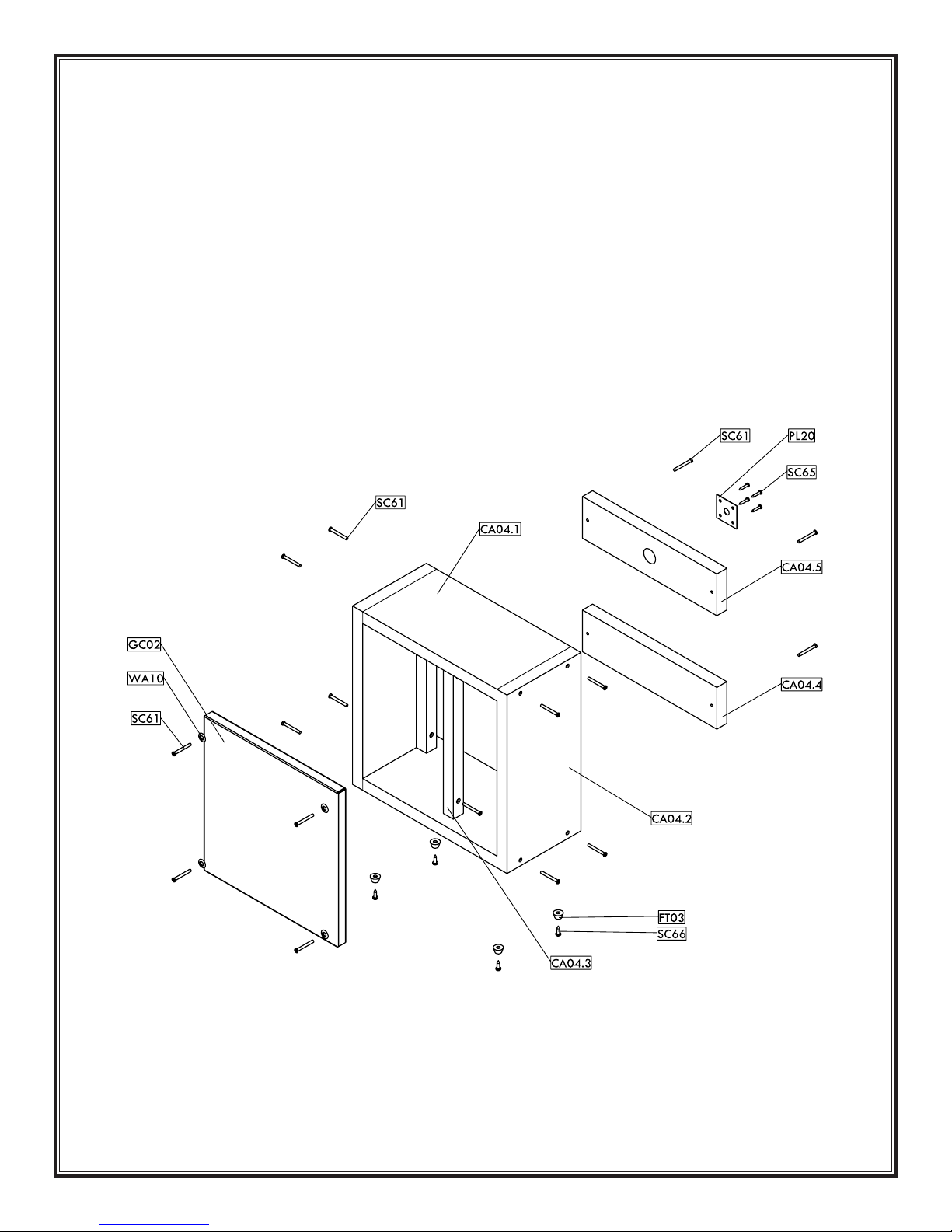

There are three components to your 1x8: the cabinet, the baffle board, and the hookup cable. You can

complete these in any order, but we think the process will be most efficient if you work on them in the

order in which we present them here. In any case, READ THE WHOLE THING THROUGH BEFORE

TIP: Empty

the parts of the kit onto a

cookie sheet or into a big fruit

bowl, NOT onto the cluttered

workbench, or onto the living room

carpet! This will protect you from

losing tiny parts.