7 Temporary operation of lift............................................................................... 30

7.1 Connecon .................................................................................................30

7.2 Operaon ...................................................................................................30

7.3 Disconnecon.............................................................................................30

8 Electrical

and

hydraulic drawings ...................................................................... 31

8.1 ZHDN 2500-150 ..........................................................................................31

8.2 ZHD 2500-150, angle sensors .....................................................................32

8.3 Connecngcontroldevice .........................................................................33

8.4 Connecngcontroldevice .........................................................................34

8.5 Connecngcabinswitchandopenplaormalarm....................................35

9 Connection unit ............................................................................................... 36

9.1 Operanginformaon................................................................................36

9.2 Autolt........................................................................................................41

9.3 Funconalschemacdrawing....................................................................42

9.4 Restriconofuseofcontroldevice ............................................................43

9.5 Sensor

....................................................................................................44

9.6 Hydraulic unit .............................................................................................45

10 Marking and decals .......................................................................................... 46

10.1 Summary ....................................................................................................46

10.2 Load diagram..............................................................................................47

10.3 Idencaonplate.....................................................................................47

10.4 Work area ..................................................................................................47

10.5 Driver'sinstrucons....................................................................................48

10.6 Danger area ...............................................................................................48

10.7 Warning tape .............................................................................................48

10.8 CE marking..................................................................................................49

10.9 Warningags.............................................................................................49

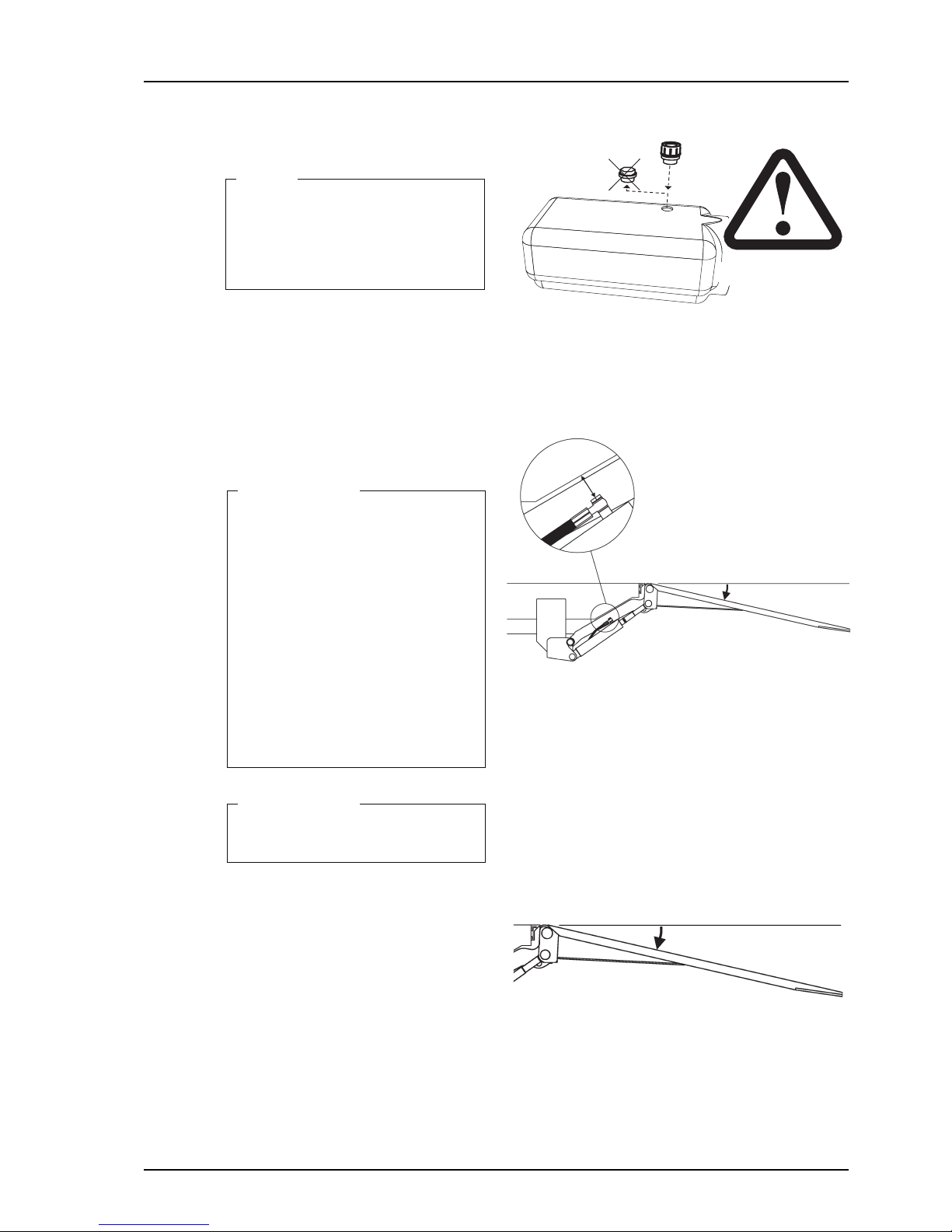

11 Lubrication and fluid level check....................................................................... 50

11.1 Lubricaon..................................................................................................50

11.2 Fluid level check .........................................................................................50

12 Testing and verification .................................................................................... 51

12.1 Stacloadtest ............................................................................................51

12.2 Dynamic load test.......................................................................................52

12.3 Testofsafetyfuncons...............................................................................52

13 Disassembly ..................................................................................................... 53

14 Specifications .................................................................................................. 54

14.1 Weights ......................................................................................................54

14.2 Centre of gravity .........................................................................................55

14.3 Maximumpowerconsumpon-Minimumrecommendedconductorcrossseconal

area ............................................................................................................56

14.4 Loading diagram .........................................................................................57

14.5 Tightening torque .......................................................................................58