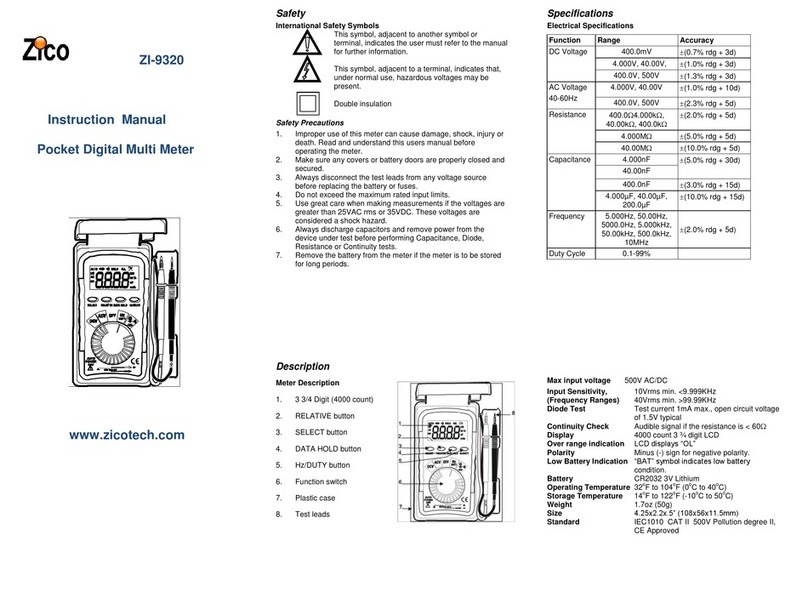

SAFETY INFORMATION

The following safety information must be observed to insure

maximum personal safety during the operation at this meter:

Do not use the meter if the meter or test leads look

damaged, or if you suspect that the meter is not

operating properly.

Never ground yourself when taking electrical

measurements. Do not touch exposed metal pipes,

outlets, fixtures, etc., which might be at ground potential.

Keep your body isolated from ground by using dry

clothing, rubber shoes, rubber mats, or any approved

insulating material.

Turn off power to the circuit under test before cutting,

unsoldering, or breaking the circuit. Small amounts of

current can be dangerous.

Use caution when working above 60V dc or 30V ac rms.

such voltages pose a shock hazard.

When using the probes, keep your fingers behind the

finger guards on the probes.

Measuring voltage which exceeds the limits of the

multimeter may damage the meter and expose the

operator to a shock hazard. Always recognize the meter

voltage limits as stated on the front of the meter.

Never apply voltage or current to the meter that

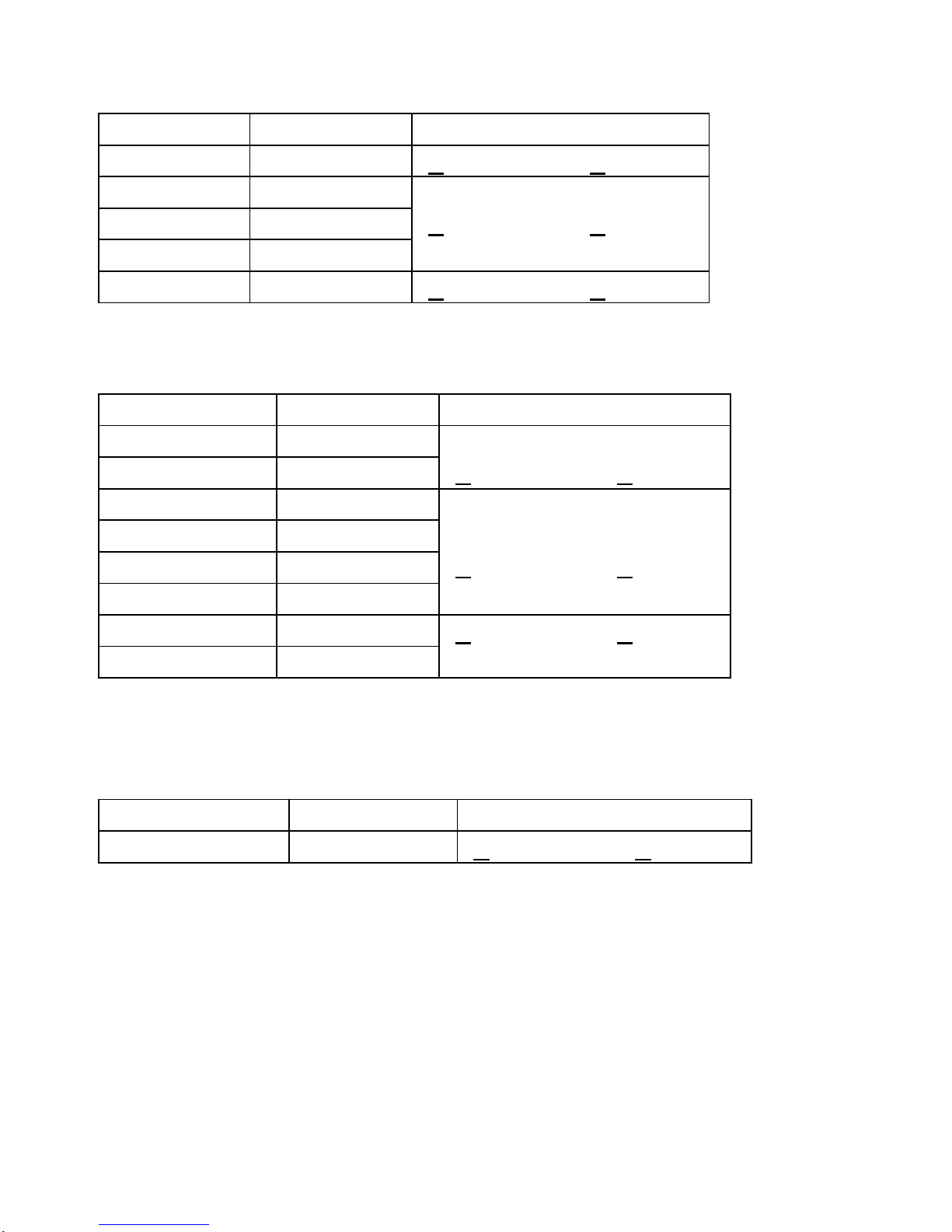

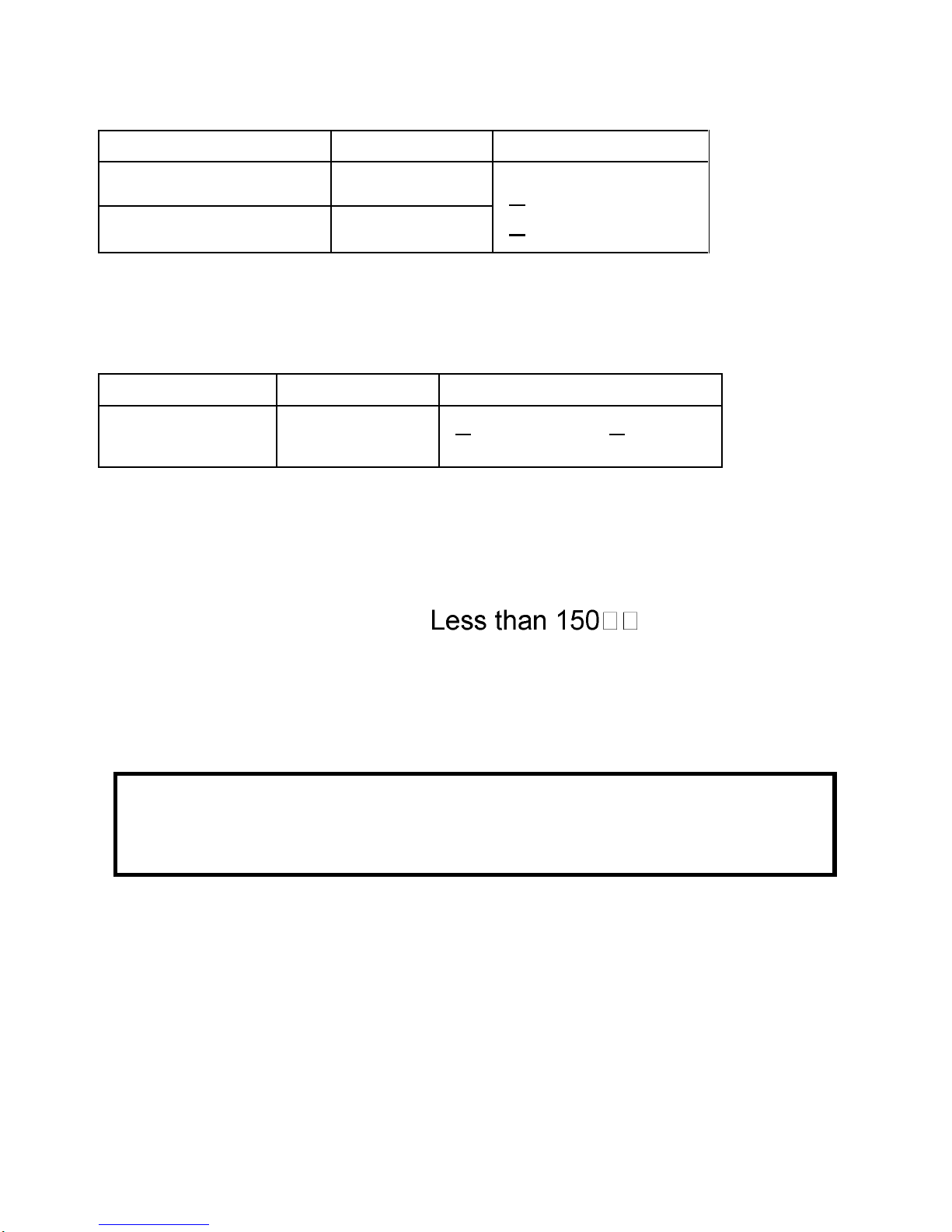

exceeds the specified maximum: