87100 v1.12 09.22 FlushMaster Page 5 of 12

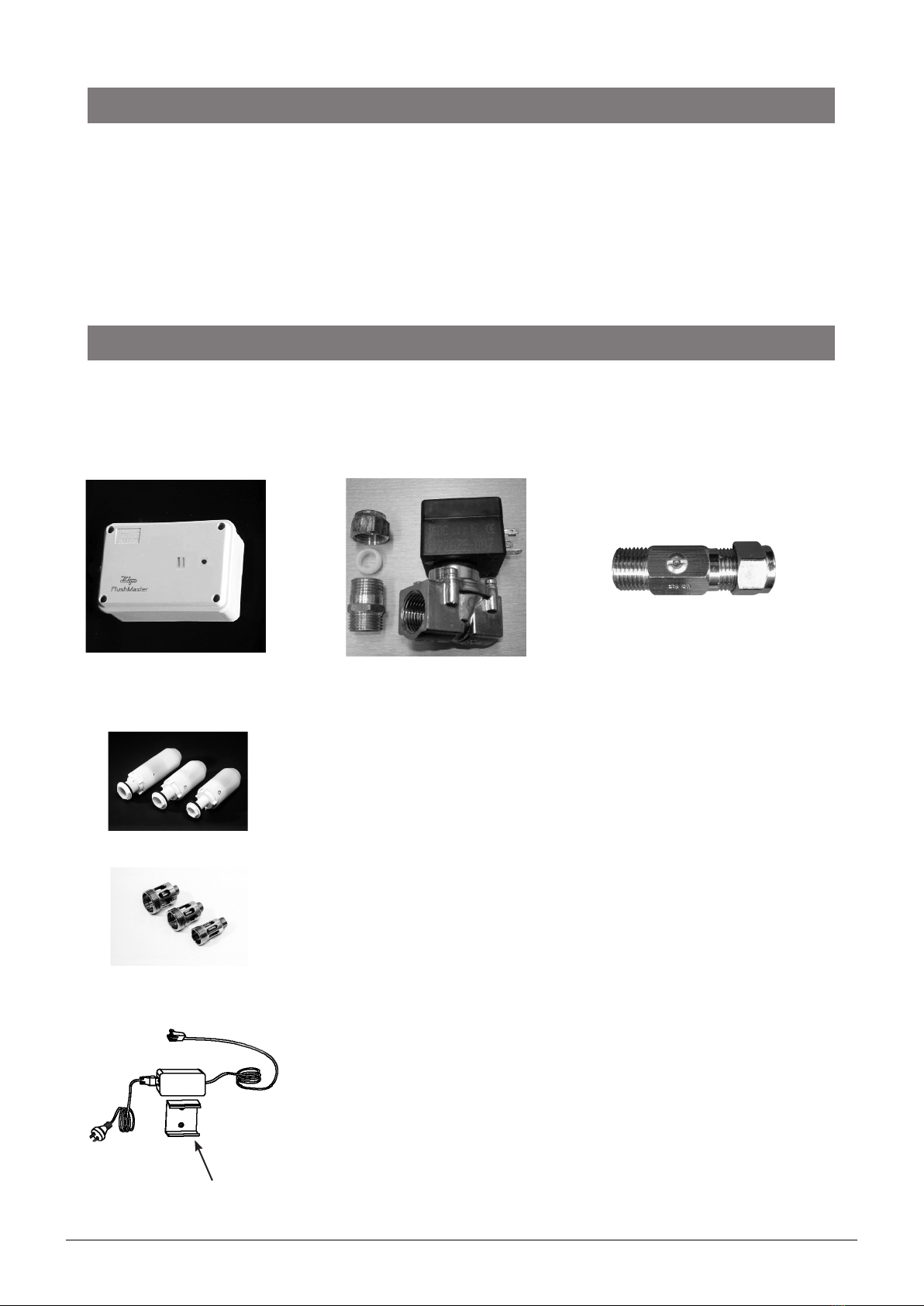

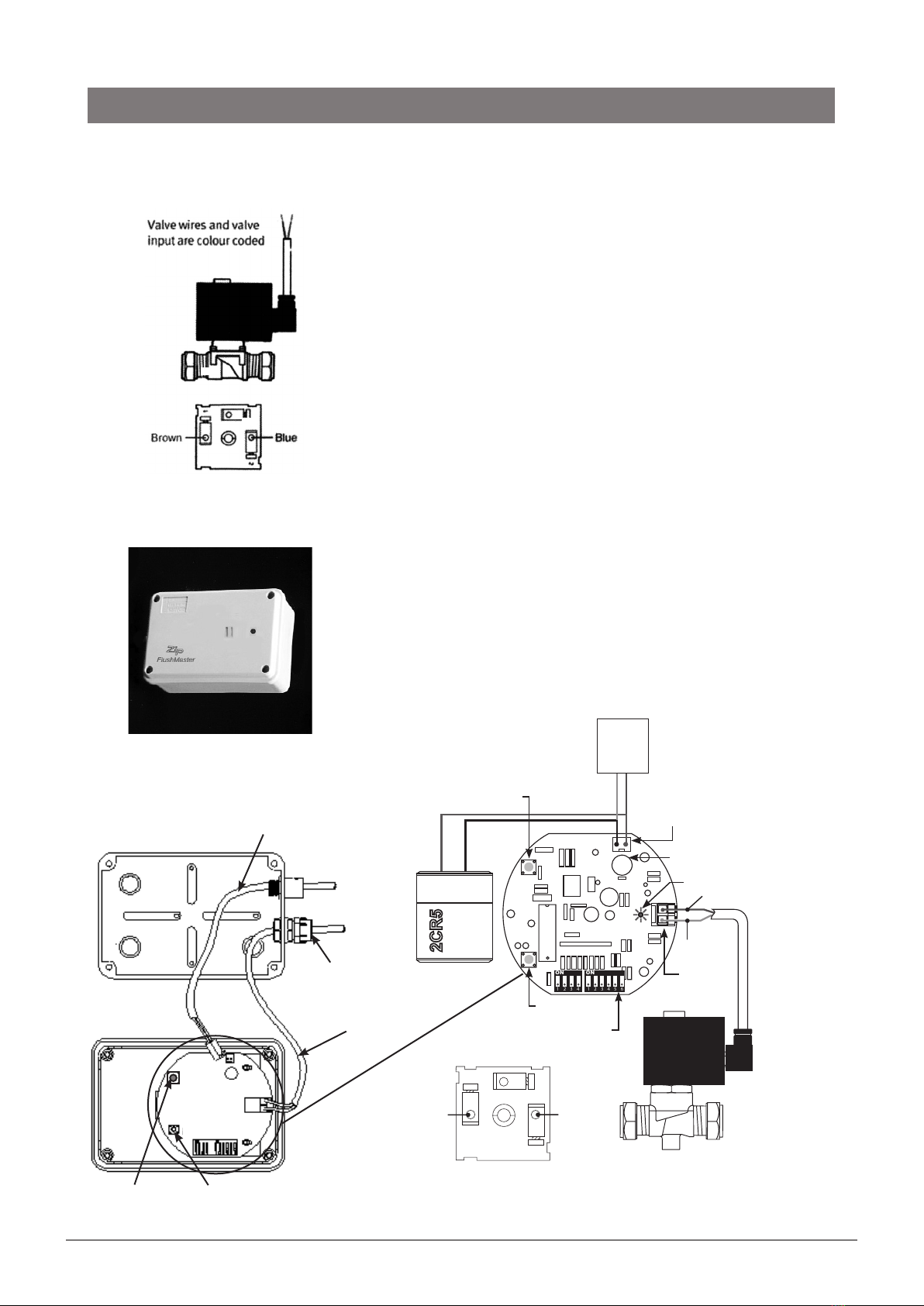

Latching valve (solenoid)

Turn off the mains water supply. An isolating valve must be

supplied and installed in accordance with AS/NZS3500.

Position the latching valve as near to the cistern as possible,

and preferably upright, as shown in the diagram.

Cut the supply pipe and purge any debris or swarf.

Fit the latching valve (15mm OD), ensuring correct flow

direction.

Restrictor installation

The Restrictaflow is designed to save water and to reduce the

flow, particularly when used on single stall installations. The

Restrictaflow is normally required with operating pressures

greater than 700kPa.

Fit the Restrictaflow between the isolating valve and the

latching valve.

The Restrictaflow may be drilled out (in 0.5mm increments)

or removed, when servicing multiple stalls and a higher flow

is required, or when there is insufficient water pressure.

Autosyphon Installation

• More than one cistern can be fed from a single latching

valve, but for accurate balancing, do not connect together

more than two cisterns.

• The balance of water can be achieved by keeping the

supply pipe length to each cistern as equal in length as

possible.

• If this is not practical, fit a flow restrictor of equal rating at

the entry to each cistern.

• Remove the existing filling mechanism from the cistern,

including the float and aspirin washer, to permit

unrestricted inlet of the water. The flow of water into the

cistern is controlled by the latching valve.

• Remove the existing manual flushing mechanism from the

cistern, and fit the syphon to the outlet hole as shown in

the diagram. Connect the sparge pipe to the protruding

thread from the syphon.

• To adjust the auto syphon height within the cistern, add

a second locking nut to the inside of the cistern and wind

the second nut up or down.

• Adjust the height of the syphon so that the flush

triggering level remains below the level of the cistern

overflow pipe.

• An air gap must always remain between the cistern water

level and the inlet water pipe level, to prevent backflow.

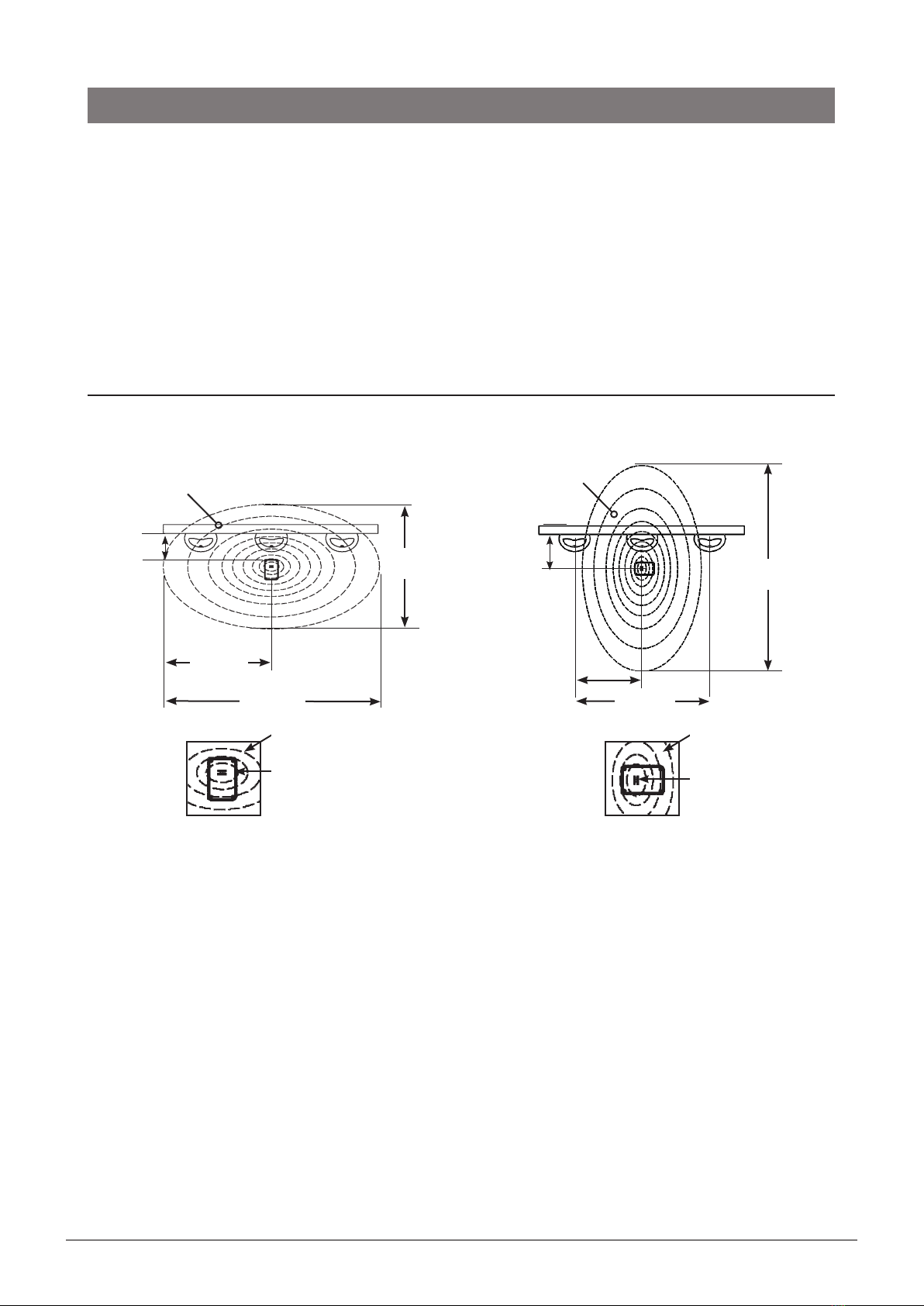

Airbreak Installation

• The air break must be fitted in a vertical position. Fitting in

a position other than vertical will result in leakage.

Latching

valve

INOUT Water

Flow

Installation

Water level

Auto

syphon

Outlet

hole

Sparge

pipe

Overflow

pipe

Air gap

water

flow

Restrictaflow

(if required)

Latching

valve

Latching

valve

Air break

fitting

Sparge

pipe

Must be

vertical

water

flow

Restrictaflow

(if required)