ZMC304X/306X Hardware Manual Version1.3

2

Contents

ZMC304X306X Hardware Manual...................................................................................................1

Chapter I Introduction of Controllers................................................................................................1

1.1 Connection Configuration...................................................................................................1

1.2 Installation And Programming............................................................................................2

1.3 Features...............................................................................................................................3

Chapter II Hardware Description......................................................................................................4

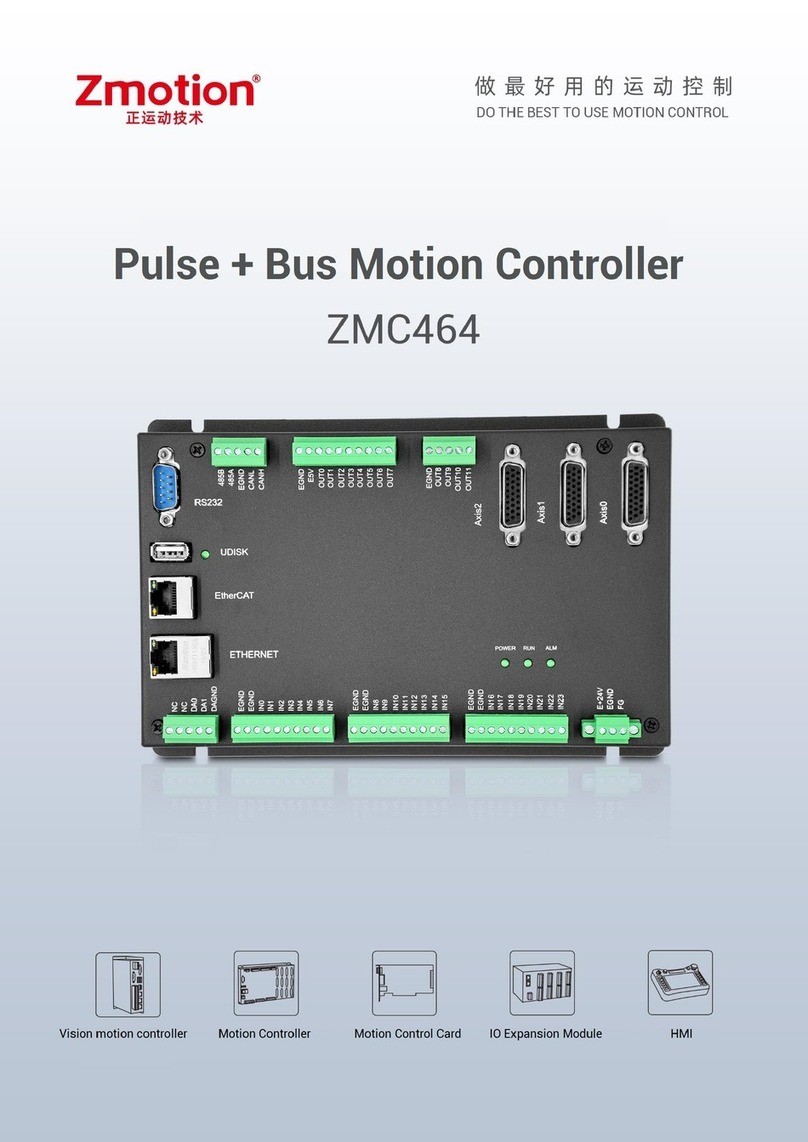

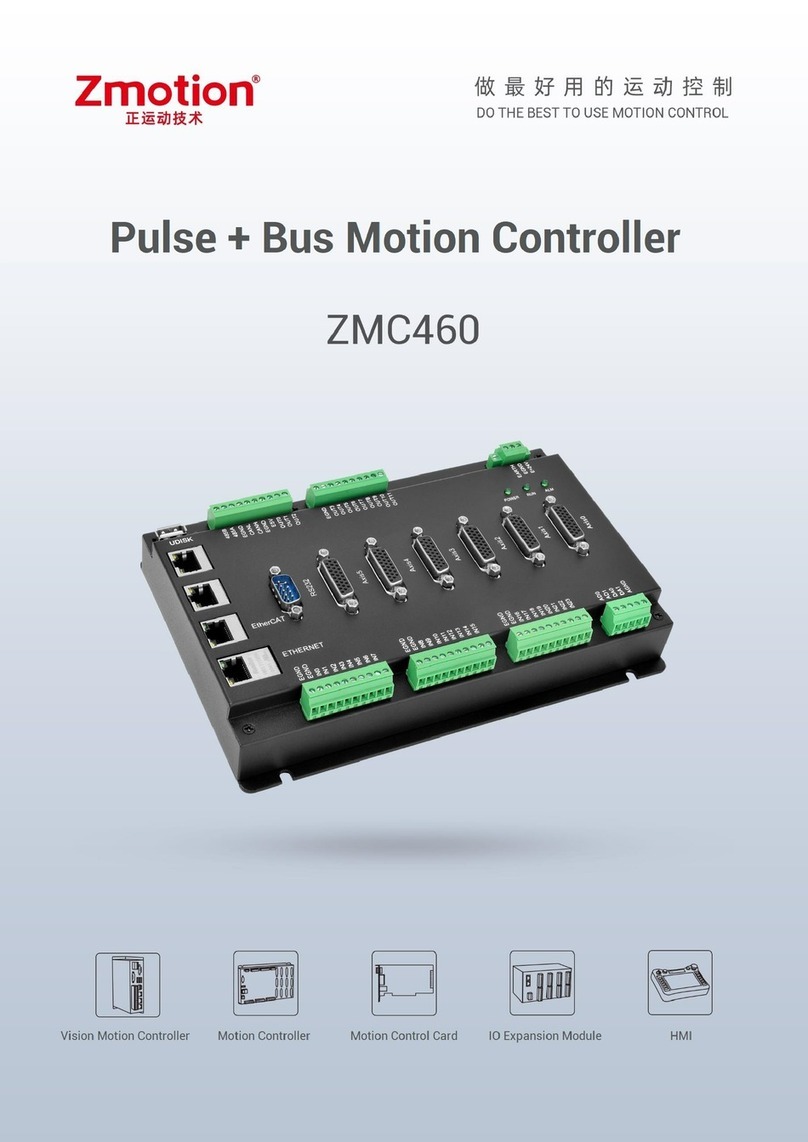

2.1 ZMC304X/306X Series Controller.....................................................................................4

2.1.1 Order Information ....................................................................................................5

2.2 Wiring Reference ................................................................................................................6

2.2.1 Power Interface........................................................................................................7

2.2.2 Communication Interface.........................................................................................8

2.2.3 RS232 Interface........................................................................................................9

2.2.4 General Input............................................................................................................9

2.2.4.1 Input 0-7......................................................................................................10

2.3.4.2 Input 8-15....................................................................................................10

2.2.4.3 Input 16-23..................................................................................................11

2.2.5 General Output.......................................................................................................11

2.2.5.1 Output 0-7...................................................................................................12

2.2.5.2 Output 8-11 .................................................................................................12

2.2.6 ADDA Signals........................................................................................................13

2.2.7 USB Drive..............................................................................................................13

2.2.8Axis Interface.........................................................................................................13

2.2.8.1 Wiring Reference For Low-speed Differential Pulse Or Encoder Axis ......15

2.2.8.2 Wiring Reference For High-speed Differential Pulse Or Encoder Axis......17

Chapter III Expansion Module........................................................................................................19

3.1 Wiring Reference For CAN, Input, OutputAnd Power....................................................19

Chapter IV Common Problems.......................................................................................................20