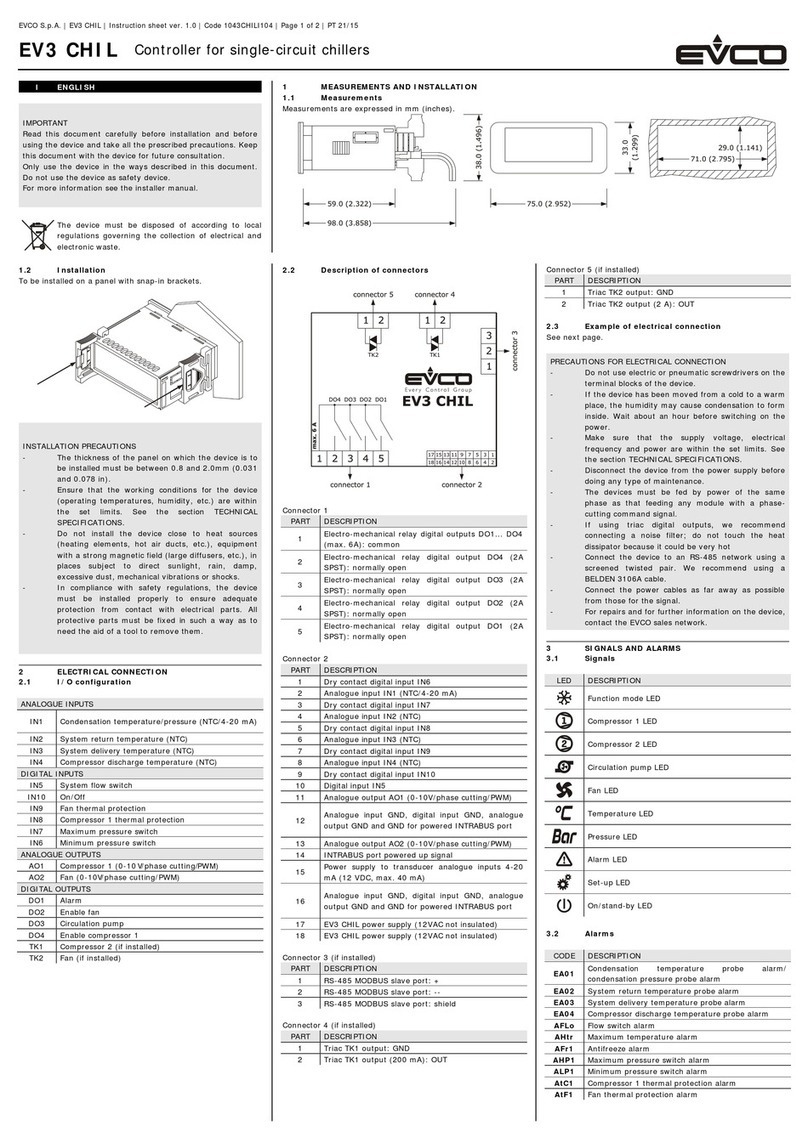

EVCOS.p.A.|EV3802|Instructionsheetver.2.0|Code1043802E203|Page2of3|PT49/20

nEG temperature controlled blast freezing and conservation

3. Touch the DOWN key again to see the cabinet temperature.

4. Touch the SET key (or take no action for 15 s) to exit the proce-

dure.

After a power failure during a cycle, the cycle is automatically reactivated from the phase it was

in at the moment the power failed. If power fails during blast chilling/freezing, it is reactivated

from the beginning.

5.4 Activating the last cycle carried out

Check that the keypad is not locked and that defrosting is not active.

1. Touch the START/STOP key for 2 s.

2.

Touch the START/STOP key within 60 s: the display will show the

duration of the time controlled blast chilling/freezing or the prod-

uct temperature at the end of the temperature controlled blast

chilling/freezing.

3. Touch the SET key.

4. Touch the UP or DOWN key within 15 s to set the value.

5. Touch the SET key (or take no action for 15 s).

6. Touch the START/STOP key again within 15 s.

The settings are temporary: when a new cycle is activated (and after a power failure), the de-

vice will restore the r1/r2 and r3/r4 values.

5.5 Interrupting an operating cycle

Check that the keypad is not locked.

1. Touch the START/STOP key for 2 s.

6 ADDITIONAL FUNCTIONS

6.1 Viewing compressor and evaporator fan status

Check that the keypad is not locked.

1. Touch the DOWN key once (to view compressor status) or twice

(to view evaporator fan status).

LAB. MEANING FOR COMPRESSOR

C-1 compressor on

C-0 compressor off

C-P compressor protection in progress

LAB. MEANING FOR EVAPORATOR FANS (if u0 = 1)

F-1 evaporator fans on

F-0 evaporator fans off

F-P evaporator fan delay in progress

2. Touch the SET key (or take no action for 15 s) to exit the proce-

dure.

7 SETTINGS

7.1 Setting first level configuration parameters

1. Touch the SET key for 4 s: the display will show the label “PA”.

2. Touch the UP or DOWN key to select a parameter.

3. Touch the SET key.

4. Touch the UP or DOWN key within 15 s to set the value.

5. Touch the SET key (or take no action for 15 s).

6. Touch the SET key for 4 s (or take no action for 60 s) to exit the

procedure.

7.2 Setting second level configuration parameters

1. Touch the SET key for 4 s: the display will show the label “PA”.

2. Touch the SET key.

3. Touch the UP or DOWN key within 15 s to set the PAS value (de-

fault “-19”).

4. Touch the SET key (or take no action for 15 s): the display will

show the label “CA1”.

5. Touch the UP or DOWN key to select a parameter.

6. Touch the SET key.

7. Touch the UP or DOWN key within 15 s to set the value.

8. Touch the SET key (or take no action for 15 s).

9. Touch the SET key for 4 s (or take no action for 60 s) to exit the

procedure.

7.3 Restoring factory (default) settings and saving customised settings

N.B.

- check that the factory settings are appropriate; see the section CONFIGURATION

PARAMETERS.

- saving customised settings overwrites the factory settings.

1. Touch the SET key for 4 s: the display will show the label “PA”.

2. Touch the SET key.

3. Touch the UP or DOWN key within 15 s to set the value.

VAL. MEANING

149 value for restoring the factory information (default)

161 value for saving customised settings

4.

Touch the SET key (or take no action for 15 s): the display will

show the label “dEF” (for setting the “149” value) or the label

“MAP” (for setting the “161” value).

5. Touch the SET key.

6. Touch the UP or DOWN key within 15 s to set “4”.

7.

Touch the SET key (or take no action for 15 s): the display will

show “- - -” flashing for 4 s, after which the device will exit the

procedure.

8. Disconnect the device from the power supply.

9. Touch the SET key for 2 s before action 6 to exit the procedure

beforehand.

8 CONFIGURATION PARAMETERS

8.1 First level parameters

NO.

PAR. DEF. REGULATION MIN... MAX.

8 r0 2.0 r7, r8, r9 and rA differential 1... 15 °C/°F

9

r1

90

duration time controlled blast

chilling 1... 600 min

10

r2

240

duration time controlled blast

freezing 1... 600 min

11

r3

3.0

product temperature at end of

temperature controlled blast

chilling

-99... 99 °C/°F

12

r4

-18.0

product temperature at end of

temperature controlled blast

freezing

-99... 99 °C/°F

13

r5

90

maximum duration temperature

controlled blast chilling 1... 600 min

14

r6

240

maximum duration temperature

controlled blast freezing 1... 600 min

15

r7

0.0

cabinet setpoint during blast

chilling -99... 99 °C/°F

16

r8

-40.0

cabinet setpoint during blast

freezing -99... 99 °C/°F

17

r9

2.0

cabinet setpoint during conserva-

tion after blast chilling -99... 99 °C/°F

18

rA

-20.0

cabinet setpoint during conserva-

tion after blast freezing -99... 99 °C/°F

8.2 Second level parameters

NO.

PAR. DEF. ANALOGUE INPUTS MIN... MAX.

1 CA1 0.0 cabinet probe offset -25... 25 °C/°F

2 CA2 0.0 needle probe offset -25... 25 °C/°F

3 P0 1 type of probe 0 = PTC 1 = NTC

4 P1 1 enable decimal point °C 0 = no 1 = yes

5 P2 0 temperature measurement unit 0 = °C 1 = °F

6 P3 1 enable needle probe 0 = no 1 = yes

7 P8 5 display refresh time 0... 250 s : 10

NO.

PAR. DEF. REGULATION MIN... MAX.

8 r0 2.0 r7, r8, r9 and rA differential 1... 15 °C/°F

9

r1

90

duration time controlled blast

chilling 1... 600 min

10

r2

240

duration time controlled blast

freezing 1... 600 min

11

r3

3.0

product temperature at end of

temperature controlled blast

chilling

-99... 99 °C/°F

12

r4

-18.0

product temperature at end of

temperature controlled blast

freezing

-99... 99 °C/°F

13

r5

90

maximum duration temperature

controlled blast chilling 1... 600 min

14

r6

240

maximum duration temperature

controlled blast freezing 1... 600 min

15

r7

0.0

cabinet setpoint during blast

chilling -99... 99 °C/°F

16

r8

-40.0

cabinet setpoint during blast

freezing -99... 99 °C/°F

17

r9

2.0

cabinet setpoint during conserva-

tion after blast chilling -99... 99 °C/°F

18

rA

-20.0

cabinet setpoint during conserva-

tion after blast freezing -99... 99 °C/°F

19

rb

1

type of cycle enabled

0 = blast chilling and con-

servation

1 = blast chilling/freezing

and conservation

2 = blast freezing and con-

servation

20

rc

5.0

minimum gap to pass first phase

of needle probe test

0... 99 °C/°F

0 = disabled

first phase ok if [(needle

temperature - cabinet tem-

perature) > rc] 3 times out of

5, checked every 10 s

21

rd

60

duration second phase needle

probe test

1... 99 s

second phase ok if [(needle

temperature - cabinet tem-

perature) > 1 °C/°F] 6 times

out of 8 (compared to previ-

ous test), checked every

(rd/8) s

NO.

PAR. DEF. COMPRESSOR MIN... MAX.

22

C0

3

compressor-on delay from cycle

activation and power-on 0... 240 min

23

C1

5

delay between two compressor

switch-ons 0... 240 min

24

C2 3 minimum compressor-off time 0... 240 min

25

C3 0 minimum compressor-on time 0... 240 s

26

C4

10

compressor-off time in cabinet

probe alarm during conservation 0... 240 min

27

C5

10

compressor-on time in cabinet

probe alarm during conservation

after blast chilling

0... 240 min

28

C6

20

compressor-on time in cabinet

probe alarm during conservation

after blast freezing

0... 240 min

29

C11

0

needle probe function in event of

cabinet probe error

0 = needle probe

1 = needle probe and cabi-

net probe

NO.

PAR. DEF. DEFROST MIN... MAX.

30

d0

8

automatic defrost interval

0... 99 h

0 = manual only

31

d3 30 defrost duration 0... 99 min

32

d7 2 dripping time 0... 15 min

NO.

PAR.

DEF.

ALARMS (active during conserva-

tion) MIN... MAX.

33

A1

10.0

low temperature alarm threshold

(relative to r9 and rA)

0... 99 °C/°F

r9 - A1 and rA - A1

differential = 2 °C/4 °F

34

A2 1 enable low temperature alarm 0 = no 1 = yes

35

A4

10.0

high temperature alarm thresh-

old (relative to r9 and rA)

0... 99 °C/°F

r9 + A4 and rA + A4

differential = 2 °C/4 °F

36

A5 1 enable high temperature alarm 0 = no 1 = yes

37

A6

15

high/low temperature alarm de-

lay from conservation 0... 240 min

38

A7

15

high/low temperature alarm de-

lay 0... 240 min

39

A8

15

high temperature alarm delay

post-defrosting 0... 240 min

40

A9

15

high temperature alarm delay

from door closure 0... 240 min

if i0 = 0 or 1

41

AA

5

buzzer duration after blast

chilling/freezing 0... 240 s

NO.

PAR.

DEF.

EVAPORATOR FANS (always on

during defrosting) MIN... MAX.

42

F0

2

evaporator fan mode during blast

chilling/freezing 0 = off 1 = on

2 = on if compressor on

43

F2

1

evaporator fan mode during con-

servation 0 = off 1 = on

2 = on if compressor on

44

F8

0

evaporator fan delay from de-

frost activation 0... 99 min

NO.

PAR. DEF. DIGITAL INPUTS MIN... MAX.

45

i0

1

door switch/multi-purpose input

function

0 = evaporator fans off

1 = compressor + evapora-

tor fans off

2 = alarm iA

3 = after 10 s evaporator

fans off

4 = after 10 s compressor +

evaporator fans off

46

i1

0

activation door switch/multi-

purpose input

0 = with contact closed

1 = with contact open

2 = disabled

47

i2

30

door open alarm delay

-1... 120 min

-1 = disabled

if i0 = 0 or 1

48

i3

15

maximum time for inhibiting reg-

ulation with door open

-1... 120 min

-1 = until closed

if i0 = 0 or 1

49

i7

0

compressor-on delay from multi-

purpose input alarm reset -1... 120 min

-1 = disabled

NO.

PAR. DEF. DIGITAL OUTPUTS MIN... MAX.

50

u0

0

auxiliary output configuration

0 = defrosting

1 = evaporator fans

N. PAR. DEF. DATA-LOGGING EVLINK MIN... MAX.

51

Hr0 - unused -

52

bLE

1

serial port configuration for con-

nectivity

0 = free

1 = forced for EVconnect or

EPoCA

2-99= EPoCA local network

address

53

rE0 15 data-logger sampling interval 0... 240 min

NO.

PAR. DEF. MODBUS MIN... MAX.

52

LA 247 MODBUS address 1... 247

53

Lb

2

MODBUS baud rate

0 = 2,400 baud

1 = 4,800 baud

2 = 9,600 baud

3 = 19,200 baud

54

LP

2

MODBUS parity

0 = none 1 = odd

2 = even

NO.

PAR. DEF. MODBUS MIN... MAX.

55

E0

247

quick setting of value during cy-

cle activation

0 = disabled

1 = duration of time con-

trolled blast

chilling/freezing or

product temperature at

end of temperature con-

trolled blast

chilling/freezing

2 = duration of time con-

trolled blast

chilling/freezing and/or

cabinet setpoint during

blast chilling/freezing

3 = duration of time con-

trolled blast

chilling/freezing and

cabinet setpoint during

blast chilling/freezing or

product temperature at

end of temperature con-

trolled blast

chilling/freezing and

cabinet setpoint during

blast chilling/freezing

56

E9 - unused -

NO.

PAR. DEF. SECURITY MIN... MAX.

57

PAS -19 password -99... 999

58

PA1 426 level 1 password -99... 999

59

PA2 824 level 2 password -99... 999

9 ALARMS

CODE

MEANING RESET TO CORRECT

Pr1 cabinet probe alarm automatic - check P0

Pr2 needle probe alarm automatic - check integrity of the probe

- check electrical connection

AL low temperature alarm automatic check A1 and A2

AH high temperature alarm automatic check A4 and A5

id door open alarm automatic check i0 and i1

iA multi-purpose input alarm automatic check i0 and i1

10 TECHNICAL SPECIFICATIONS

Purpose of the control device: function controller.

Construction of the control device: built-in electronic device.

Housing: black, self-extinguishing.

Category of heat and fire resistance: D.

Measurements:

75.0 x 33.0 x 59.0 mm (2 15/16 x 1 5/16 x

2 5/16 in) with fixed screw terminal blocks 75.0 x 33.0 x 81.5 mm (2 15/16 x 1 5/16 x

3 3/16 in) with plug-in screw terminal blocks

Mounting methods for the control device:

to be fitted to a panel, snap-in brackets pro-

vided

Degree of protection provided by the casing: IP65 (front).

Connection method:

fixed screw terminal blocks for

wires up to 2.5 mm²

plug-in screw terminal blocks

for wires up to

2.5 mm² (on request)

Pico-Blade connector.

Maximum permitted length for connection cables:

power supply: 10 m (32.8 ft) analogue inputs: 10 m (32.8 ft)

digital inputs: 10 m (32.8 ft) digital outputs: 10 m (32.8 ft).

Operating temperature: from 0 to 55 °C (from 32 to 131 °F)

Storage temperature: from -25 to 70 °C (from -13 to 158 °F).

Operating humidity:

relative humidity without condensate from

10 to 90%.

Pollution status of the control device: 2.

Compliance:

RoHS 2011/65/EC

WEEE 2012/19/EU

REACH (EC) Regulation

no. 1907/2006

EMC 2014/30/EU LVD 2014/35/EU.

Power supply:

230 VAC (+10% -15%), 50/60 Hz (±3 Hz),

max. 2 VA insulated in EV3... N7 115 VAC (+10% -15%), 50/60 Hz (±3 Hz),

max. 2 VA insulated in EV3... N5.

Earthing methods for the control device: none.

Rated impulse-withstand voltage: 4 KV.

Over-voltage category: III.

Software class and structure: A.

Analogue inputs:

2 for PTC or NTC probes (cabinet probe and

needle probe).

PTC probes: Type of sensor: KTY 81-121 (990 @ 25 °C, 77 °F)

Measurement field: from -50 to 150 °C (from -58 to 302 °F)

Resolution: 0.1 °C (1 °F).

NTC probes: Type of sensor: ß3435 (10 K@ 25 °C, 77 °F)

Measurement field: from -40 to 105 °C (from -40 to 221 °F)

Resolution: 0.1 °C (1 °F).

Digital inputs: 1 dry contact (door switch/multi-purpose).

Dry contact: Type of contact: 5 VDC, 1.5 mA

Power supply: none

Protection: none.

Digital outputs:

2 with electro-mechanical relay (compressor and auxiliary

relay).

Compressor relay (K1): SPST, 16 A res. @ 250 VAC

Auxiliary relay (K2): SPDT, 8 A res. @ 250 VAC.

Type 1 or Type 2 actions: type 1.

Additional features of Type 1 or Type 2 ac-

tions: C.

Displays: custom display, 3 digit, with function icons.

Alarm buzzer: built-in.

Communications ports:

1 TTL MODBUS slave port for EVconnect app,

EPoCA remote monitoring system or for

BMS.