HCT evc User manual

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 1

evc/epcController

WithSAEJ1939Interface

High Country Tek, Inc. reserves the right to improve this product at any time and without notice. This manual

may contain mistakes and printing errors. The information in this publication is regularly checked and

corrections made in the next issue. Please check our website or contact our customer support for latest version.

HCT accepts NO liability for technical mistakes or printing errors or their consequence

evc/epc

Electronic Valve Controller

User Guide

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 2

evc/epcController

WithSAEJ1939Interface

High Country Tek, Inc. (HCT) is North America’s foremost independent designer and producer of

modular, ruggedized digital and analog electronic controller products for the fluid power industry.

From our factory in California, we build, test and produce ‘specialty’ controllers for specific functions as

well as our ‘DVC family’ of fully adaptable user programmable units that can be integrated to enable large

area networked system solutions.

The modules are used in mobile, industrial and marine applications. They are also applied successfully in

other industry segments.

HCT’s every module is encapsulated in solid flame resistant material for maximum durability, electrical

integrity and complete environmental security. We deliberately select the highest quality components at

all times, ensuring 100% operating products.

HCT is a market leader in many application arenas, including hydraulic generator, e-Fan and hydraulic

fan system controls. These controllers realize significant fuel, emission and operational savings by

optimizing the applications.

HCT’s market neutrality offers dependable integration with any hydraulic OEM products for easy, simple

and accurate control of valves, pumps, sub-systems or systems.

Our best-in-class customer service and product reliability is well known and trusted throughout the fluid

power network and we look forward to working with you in the future.

For our latest information, products, updates, guides and accessories, please visit us at:

www.hctcontrols.com

The information in this publication is intended as a guide only, and High Country Tek, Inc. (HCT) takes

NO responsibility for usage and implementation in any user entered values into the provided GUI

structure.

HCT strongly suggests that the user attends one of the product training courses to ensure correct and full

understanding of this information and to learn further optimized methods of control techniques.

Please contact HCT customer service to book one of the scheduled training dates or discuss arranging a

course specific to your company needs.

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 3

evc/epcController

WithSAEJ1939Interface

Contents

Welcome .........................................................................................................................................................4

Warranty Information.......................................................................................................................................4

Product Application Guidelines .......................................................................................................................5

Software Safety...............................................................................................................................................5

Controller Specification ...................................................................................................................................6

Controller Mounting Information......................................................................................................................6

Controller Input vs Output ...............................................................................................................................7

Using the evc/epc with your PC ......................................................................................................................8

evc/epc GUI ..................................................................................................................................................10

File ........................................................................................................................................................10

Default Settings.....................................................................................................................................11

Environment ..........................................................................................................................................11

Password ..............................................................................................................................................11

Help.......................................................................................................................................................12

Exit ........................................................................................................................................................12

Dashboard, Status and Graphing Windows..........................................................................................12

Data Logging.................................................................................................................................................13

Dashboard.....................................................................................................................................................15

Output A or B Coil Settings ...........................................................................................................................16

Manual Mode ................................................................................................................................................19

Command & Error Settings ...........................................................................................................................20

Pulse Input Settings ......................................................................................................................................23

Global Settings..............................................................................................................................................24

Factory Settings ............................................................................................................................................25

SAE J1939 ....................................................................................................................................................26

Operational Modes........................................................................................................................................27

Hydraulic Valve or Pump Control..........................................................................................................27

Anti-Stall or Horsepower Management With Fixed Command .............................................................28

Anti-Stall or Horsepower Management With Variable Command.........................................................30

Dual Output With Over Speed Protection .............................................................................................31

Constant Flow Mode .............................................................................................................................32

Electrical Diagram .........................................................................................................................................33

LED flash / Diagnostic Codes .......................................................................................................................34

Module Status LED ...............................................................................................................................34

Communication Status LED..................................................................................................................34

SAE J1939 CAN Bus ....................................................................................................................................35

Command Message Format .................................................................................................................35

Status Message Format........................................................................................................................36

Analog Values Message .......................................................................................................................37

Parameter Values .................................................................................................................................37

Problems Installing the Com Port Adapters..................................................................................................39

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 4

evc/epcController

WithSAEJ1939Interface

Welcome

Welcome to the High Country Tek Inc. (HCT) evc/epc user manual.

If you have any questions, requesting new features or finding errors, please contact us @ 530-265-3236

or e-mail at info@hctcontrols.com, giving details of the issues and your contact information.

Introduction

This manual explains the installation and use of the evc/epc Digital Controllers. Users need to understand

the hazards in an electromechanical environment. Read this entire manual before installation. Pay particular

attention to caution and safety information.

Cautions

Changing setup values or operating modes while the machine is running may cause unintended machine

movement. It may lead to possible injury or death. Any moving parts should be disabled prior to

changing setup values or operating modes. In any case, exercise caution and work should be completed

only by qualified personnel.

Warranty Information

High Country Tek guarantees this product to be free of defects in materials and workmanship for one year

from the date shipped from the factory. Within this time frame, High Country Tek will provide evaluation of

warranted items free of charge. Warranty repair or replacement will be at the factory’s discretion.

Please have the units full Model / Part Number and Serial Number available when contacting the factory.

Do not return products to the factory without a RMA (Return Material Authorization) number.

Controller Updates

HCT continuously improves the controllers and makes additional information and/or features available.

Please check on-line at www.hctcontrols.com for the latest products, software update and information.

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 5

evc/epcController

WithSAEJ1939Interface

Product Application Guidelines

ALWAYS do the following

FULLY read this manual and accompanying data sheets BEFORE starting.

Isolate this unit from all other equipment BEFORE any form of welding.

Isolate the controller from ANY form of battery charging or battery boosting.

Be aware of the adjustments and reactions on the external equipment.

Operate the units within the temperature range.

Use the correct tools to do the job (i.e. P.C., software) etc.

Separate High Voltage AC cables from Low Voltage DC signal and supply cables.

Check that the units supply voltage is CORRECT, ‘ELECTRICALLY CLEAN’ and STABLE.

Make sure the controller output voltage & current is compatible with the equipment!

All unused wires / terminals should be terminated safely.

Ensure ALL connectors have no unintended SHORT or OPEN circuits.

Ensure ALL connectors are wired correctly, secure, locked in place and fully connected.

Observe all the set-up procedures in this manual.

Follow and abide by local and country health & safety standards!

NEVER do the following

Arc Weld or Charge Batteries with this module connected as damage can/will occur.

Attempt to use this unit if you are unsure of electrical OR mechanical connections or expected operation.

Use a power supply that is not rated for the output current under full load.

Allow wires to or from the unit to short circuit (to each other or chassis/cabinet etc.).

Use this controller in areas of intense Radio Frequency fields without adequate screening.

Disconnect or connect wires to or from this unit unless it isolated from the power supply.

Use this unit in temperatures that exceed the limits.

Start or operate this controller without ensuring ALL work areas are clear of personnel!

Software Safety

The GUI and controller software give the user flexibility and ease of use, even for novice users.

The GUI is not intended to be connected to a non-evc/epc unit. Care must be taken to use the correct GUI

and hardware combination. After program entries, cycle the power to ensure changes are accepted by the

unit.

When the GUI is first connected to a powered controller, a ‘Handshake’ takes place that confirms the

internal software (BIOS) is compatible with the GUI software. Only then the PC and the module are allowed

to communicate and exchange data.

If an error or miss-match is detected, or loss of communication, the GUI software will indicate “OFF LINE”

and NOT allow communications until the problem is corrected.

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 6

evc/epcController

WithSAEJ1939Interface

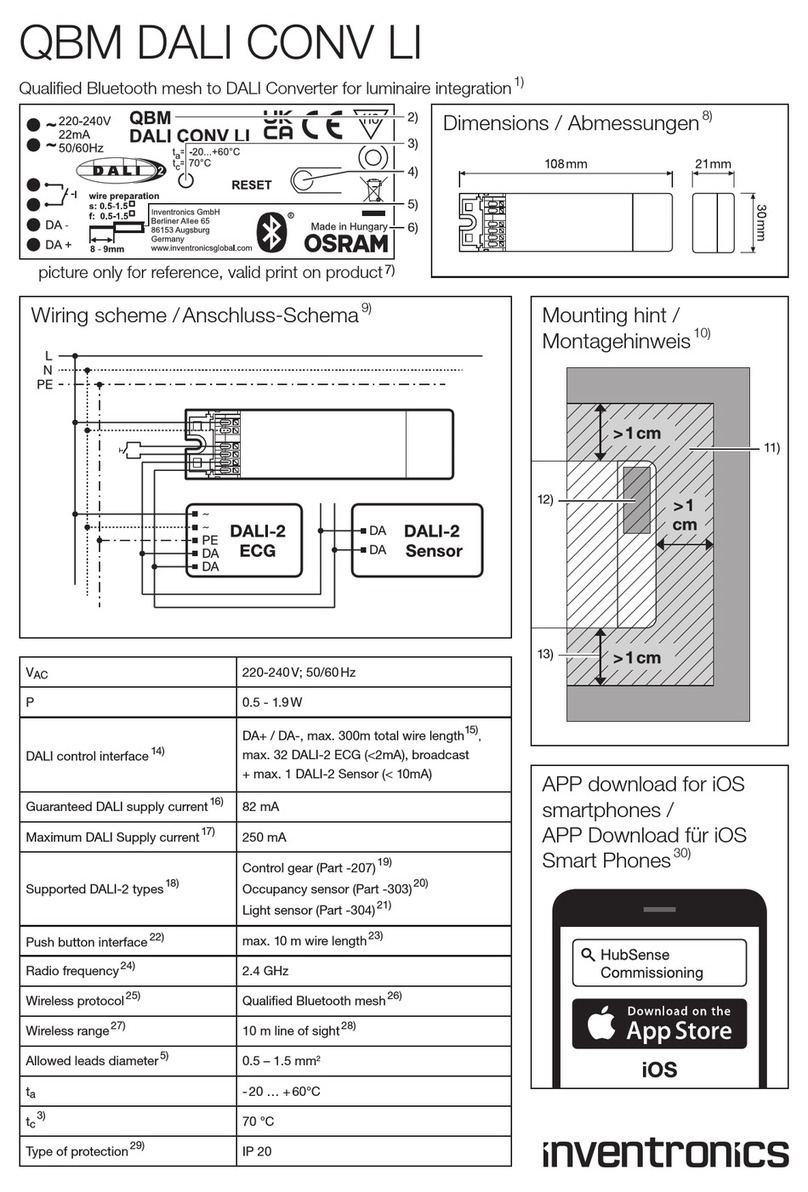

Controller Specification

Controller Mounting Information

1. Mountcontrollerinaneasilyaccessiblelocation.

2. Mountcontrollertoaflat,coolsurface.

3. Ifmountingtoahydraulicproduct,allowatleasta2mmairgapunderneaththeunit.

4. UseBOTHmountingholeswithcorrecthardware.

5. DONOTmountcontrollerwithconnectorfacingUPifpossible.

Housing Type HCT unique encapsulated block

Power Supply Voltage 9 to 32Vdc (Absolute Maximum)

Current Consumption Valve current + 50mA Quiescent (Max)

Command Inputs SAE J1939

2x switches (ON/Off)

1x analog input (0-5V,0-10V, 4-20mA)

1x analog input

(0-5V,0-10V, Pulse or Freq - 3 to 30KHz)

Input Impedance Voltage inputs = 100k

4-20mA input = 100

Outputs 2x 3A proportional PWM

(short circuit protection and open circuit alert)

1x 5Vdc ±10% regulated voltage (max 250mA)

PWM Dither Freq Software adjustable - 33 to 500Hz

Module Connector DTF15-12PB, 12-way Male

Communication Mini-B USB standard

Housing Material Black, Polycarbonate

Encapsulation Flameproof epoxy resin

Mounting 2x No.8 (5mm) screws

Temperature Range -40 to +85ºC (operational)

NEMA/IP Rating NEMA 6P/IP67

45mm

125mm

60mm

‐Prop.O/P1ON

‐Prop.O/P2ON

‐PulseI/PActive

‐Digi.I/P1Active

_Module

Status

_Comm.

Status

‐Digi.I/P2Active

www.hctcontrols.com

SN:

evc

Electronic Valve

Controller

MadeinUSA

43

9101112

21

65

78

Use2xM5(#8)screwsorbolts

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 7

evc/epcController

WithSAEJ1939Interface

Controller Input vs Output

NOTE:

Alltestsconductedat70Fambient,24Vdcsupplywith8coilandIminsettozeroandImaxsetto1A.

4-20mA Input:

Imin = 0.05A, Imax = 1A

The internal current shunt resistor is 100.

0 to +5V Input:

Imin = 0, Imax = 1A

The input impedance is 100K.

0 to +10V Input:

Imin = 0, Imax = 1A

The input impedance is 100K.

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 8

evc/epcController

WithSAEJ1939Interface

Using the evc/epc with your PC

Install the Graphical User Interface (GUI) in a host PC. Use the default file locations for easy future

update. The user has the option to choose where the program should be located.

Don’t run the GUI from a network as it needs access to certain files only in the Windows directories.

System Requirements

Windows XP, Vista or Windows7, 100MB or greater free disk space.

Insert the CD into the PC drive and follow the on-screen instructions. This will install the evc/epc GUI,

manual and help files.

Install the Com Port drivers for the evc/epc.

Start HCT Products Digital Controllers evc/epc USB Serial Drivers, CDMxxxxx_setup.exe

To insure a complete install, run the CDMxxxxx twice.

The evc/epc can be powered by +5V USB to allow configuration without connecting to a 12/24Vdc system.

A message “Supply Voltage is Low” appears on the screen. You may fully communicate, change, and

save settings to the unit. You can not drive the coil(s).

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 9

evc/epcController

WithSAEJ1939Interface

At start up the GUI searches the PC com ports for the evc/epc controller.

The default MAC ID is 1. If the evc/epc has been programmed with a different Mac ID, you can search

for the controller by “Find Module” or enter the Mac ID. The “Find Module” will restart the operation when

the unit responds with its information and Mac ID.

The MAC ID determines the module’s Command and Status PGN addresses on the SAE J1939 bus. The

user may command many evc/epc modules on a single J1939 bus. Please see SAE J1939 section.

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 10

evc/epcController

WithSAEJ1939Interface

evc/epc GUI

File

All changes made through the GUI are temporary until saved permanently.

Permanently save settings to unit: Save the settings from the RAM (temporary) memory to the unit’s

EEPROM (permanent memory).

Permanently save settings to unit & file (.dat): Permanently save the settings to the unit’s EEPROM

and to a data file that may be loaded later.

Settings will be lost if not permanently saved before power cycle.

Reset the unit with a power cycle, you must remove both the USB cable and DC power from the

unit.

Restore unit to last permanent settings saved: Reload RAM with settings stored in the EEPROM. This

will undo all changes made since the last Permanent Save.

Restore unit settings from data file (.dat): Load the data file from the PC to the evc/epc for different

modes of operation.

Restore unit from v1.03 data file: Load the previous version data file from the PC to the evc/epc for

different modes of operation.

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 11

evc/epcController

WithSAEJ1939Interface

Default Settings

There are four default modes of operation. Other modes of operations can be created using data files.

1. HP Limiting or Anti-Stall with Fixed Command

2. HP Limiting or Anti-Stall with Variable Command

3. Single Coil Pump or Valve Control

4. Dual Coil Pump or Valve Control

Environment

The Environment Menu selects the terminology for load control.

In the Automotive Environment, load control is called “Anti-Stall” and in the Agriculture environment the

same function is called “HP Limiting”.

Password

“Enter Password” unlocks certain features of the GUI.

Passwords are ‘cAsE SeNsitivE’.

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 12

evc/epcController

WithSAEJ1939Interface

Help

Reconnect with controller:The GUI will reset communication with the module, and re-read and update

all variables.

Print Settings to text: Will print all settings to your PC default printer, or print to a text file, tab delimited.

The text file may be viewed with Notepad, Word, or Excel.

About Controller: Will display information about the evc/epc, the GUI revision, serial number, contact

information etc.

Manual: Will open the folder in C:\\HCT products/Digital Controllers, or browse to other locations.

Exit

Exits the evc/epc GUI and frees up the com port and memory used by the application.

You can exit the GUI with or without saving the changes.

Dashboard, Status and Graphing Windows

They give real time overview of

the controller health, operation of

the system and condition of

inputs, outputs and any alarms.

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 13

evc/epcController

WithSAEJ1939Interface

Each graph tracks two variables that are individually scaled. Select the variable from the Pull Down

Menus. “Y” axis is automatically scaled to the respective minimum and maximum values.

To customize the scaling, simply select a value on the graph and enter the desired value.

Data Logging

“Log Data” and save it in “.xls” format. The data can be as big as your PC memory capacity.

Each log begins with a list of unit settings and is followed by real time operational information. The

sample rate depends on the workload of the PC and the evc/epc at recording. A timestamp scales the

logs appropriately. Subsequent logs may be stored in a new file or appended to the original log file by

selecting the original file.

The log file may not have all of the Excel formatting. Excel may declare an unknown file format. If it does,

select Open and the information will display normally.

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 14

evc/epcController

WithSAEJ1939Interface

Example data files are saved to your PC during the installation.

When loading factory default data files, select “Environment”, then select

the desired default file.

Default Data files will overwrite any settings in the unit.

Adjust the Coil Settings first, then other settings as needed.

In Agriculture or Automotive you will have Four files:

1. HP Limiting with Variable Command /Anti-stall with Variable Command.

Monitors RPM, the command in, and adjust the output accordingly.

2. HP Limiting with fixed command/Anti-stall with fixed command.

Monitors RPM and adjusts the output accordingly.

3. Single Coil Pump Control / Valve Control

Controls the single-coil pump/valve.

4. Dual Coil Pump Control / Valve Control

Controls the dual-coil pump(s)/valve(s).

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 15

evc/epcController

WithSAEJ1939Interface

Dashboard

PWM% A/B – displays the output for coil A

and B in the percent of duty cycle. The PWM% B

will be “Grayed Out” when Coil B is disabled.

% Demand A/B –

displays the percent of

demand for the output with respect to the

Maximum and Minimum Current settings. The %

Demand B will be “Grayed Out” when Coil B is

disabled.

Coil Current A/B – displays the output

current. The Coil B Current will be “Grayed Out”

when Coil B is disabled.

Enabled/Disabled – displays the current state of the enable input connection.

Command Volts/mAmps – Displays the voltage or current at the Command input - (pin 3).

Reference Volts – Displays the voltage at the User Reference output - (pin 2).

Supply Volts – Displays the voltage at the main Power Supply Input - (pin 1).

Average Coil Current – Applies averaging function to the displayed coil current.

A

A

C

D

D

C

B

B

E

E

F

F

G

G

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 16

evc/epcController

WithSAEJ1939Interface

Output A or B Coil Settings

Select Coil B Active for a Dual Coil Valve

Control.

Enter minimum and maximum current, dither

frequency according to the valve spec.

Enter ramp times.

“Change Settings” to apply the changes to the

unit’s temporary memory.

Fine tune these settings as required.

Always Active (ON) – Output A is always active and cannot be set to OFF.

Coil B – active (ON/OFF) – Enables/Disables Output B.

Current feedback (ON/OFF)

When Current Feedback is “ON”, coil current output is monitored and adjusted proportionally to the

demand within the coil max and min settings.

Current Feedback compensates the current due to supply voltage and coil temperature changes.

When disabled, the output’s waveform is adjusted proportionally to the demand between 0% and

100% PWM Duty Cycle.

Inverted (ON/OFF)

When Inverted is “ON”, the outputs are inversely proportional to the inputs. This is used with normally

closed valves.

When Inverted is “OFF”, the output is proportional to the input.

Coil A/B Min Current (0 to 3Amps)

Determines the min current or duty cycle when the demand is >0. Fine tune it to balance machine

safety and valve responsiveness.

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 17

evc/epcController

WithSAEJ1939Interface

Coil A/B Max Current (0 to 3Amps)

When Current Feedback is “ON”, it determines the max current.

When Current Feedback is “OFF”, the Coil A/B Min Current setting does not apply and is grayed out. The

Max Current is used as a reference for the evc/epc to declare a coil short condition when the output

current is 0.5A higher than the max setting.

The output PWM duty cycle

matches the percent of demand.

The current will change when

supply voltage and/or coil

temperature changes.

The evc/epc does not declare an

error because the output current

1.16A is not 0.5A higher than the

max setting 0.7A.

The evc/epc will declare an error

because the output current 1.16A is

0.5A higher than the max setting

0.63A.

Ramp Up (.001 to 65.000 Seconds) – Determines the time for Output A or B to ramp UP from minimum to

maximum current.

Ramp Down (.001 to 65.000Seconds) – Determines the time for Output A or B to ramp Down from

maximum to minimum current.

Coil A&B PWM Hz (33 to 500Hz) – This is the PWM or Dither frequency according to the valve spec.

(Sun cartridges are 140Hz).

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 18

evc/epcController

WithSAEJ1939Interface

Ignore Open (ON/OFF)

When Ignore Open is “ON” and Current Feedback is “ON”, the evc/epc will not declare an error when

the output duty cycle reaches 100%.

When Ignore Open is “OFF” and Current Feedback is “ON”, the evc/epc will declare an error when the

output duty cycle reaches 100%.

When Current Feedback is “OFF”, Ignore Open does not have any impact.

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 19

evc/epcController

WithSAEJ1939Interface

Manual Mode

“Manual Mode” provides a quick method of testing the outputs. It can be used to manually verify that the

system is working properly and to determine the max coil current for present conditions.

To unlock manual control, enter the OEM password. When the GUI is purchased, the OEM password is

included. You can reset it, just don’t forget it.

Caution

All settings on this tab are temporary and will immediately affect the outputs.

In manual mode all limits and controls are bypassed.

The evc/epc goes back to normal operation when exiting the GUI in manual mode.

Cycling power on the unit will reset the controller and remove manual override.

023-00354-Rev1.4 evc/epc User Manual Copyright © High Country Tek, Inc. – 2013 20

evc/epcController

WithSAEJ1939Interface

Command & Error Settings

Analog Input Active (On/Off) – Enables/Disables

the command analog input.

Analog Center Active (On/Off)

When enabled, the “Pot Center Voltage” becomes the zero demand point. One coil is driven from 0%

to 100% on either side of the zero point

Coil A is driven from the center voltage to the max voltage and coil B is driven from the center voltage

to the min voltage

This setting is used in Dual Coil Valve Control only. The “Coil Selection Active” switch is automatically

OFF when the Center Active is “ON”.

Coil Selection Active (pin 9, On/Off)

When “ON”, the state of the reverse input pin is used to determine which coil will be driven. i.e. When

the input is High, (+5V to Supply Volts) coil B is active and when Low (0V to 2.5V) coil A is active.

This feature allows the full command resolution on coil A and B. It is used in the applications that a

reciprocating action is triggered by a single high-low input.

Pot Center Error Detection at Initial Turn On

When set, the module verifies the analog input is in the center deadband range before enabling the

output(s) after the initial power up.

Once the command is centered, the outputs will be enabled.

To use this feature, the Analog Center Active has to be “ON”.

This safety feature ensures that the system will NOT immediately go to the previous settings after

cycling the power.

This manual suits for next models

1

Table of contents

Other HCT Controllers manuals

Popular Controllers manuals by other brands

Fiery

Fiery AR-PE1 Installation and service guide

Rockwell

Rockwell Micro830 installation instructions

Rockwell Automation

Rockwell Automation Allen-Bradley GuardLogix Application Technique

Inter-m

Inter-m ECS-6216P Operation manual

Inventronics

Inventronics QBM DALI CONV LI quick start guide

ACC

ACC RC-85 owner's manual