2

© Copyright 2021 Zoeller®Co. All rights reserved.

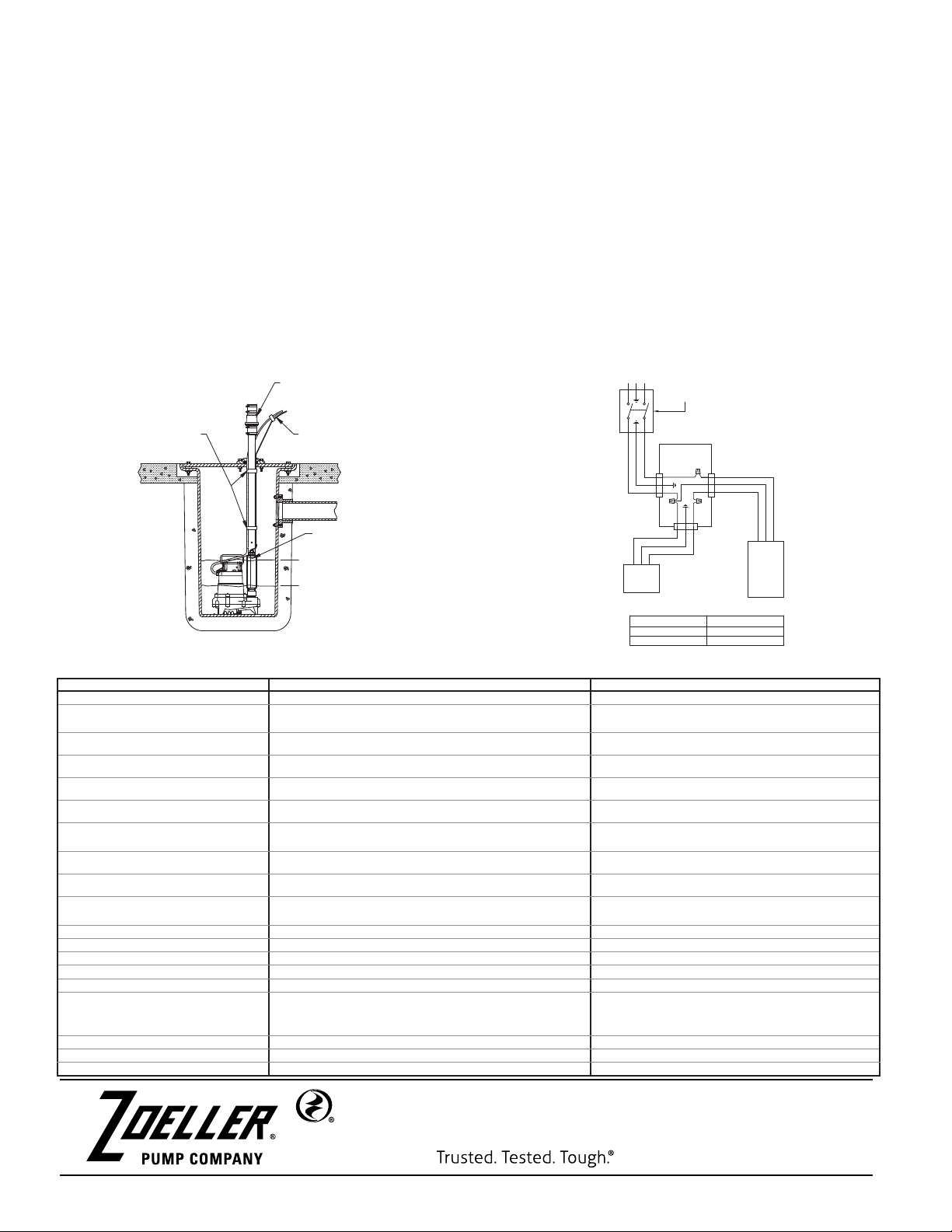

FIGURE 3

MAIL TO: P.O. BOX 16347 • Louisville, KY 40256-0347 USA

SHIP TO: 3649 Cane Run Road • Louisville, KY 40211-1961 USA

+1 (502) 778-2731 • 1-800-928-7867 • FAX +1 (502) 774-3624 visit our web site:

zoellerpumps.com

MODEL NO. SUMP SEWAGE

X

10-4660 X

53-0084 X

98-0069 X

267-0121 X

SWITCH TYPE POWER WIRE COLOR

SUMP RED

SEWAGE BLUE

DISCHARGE PIPE

CORDS SECURED TO

LEVEL

PUMP "OFF"

LEVEL

PUMP "ON"

ZOELLER UNICHECK

TO POWER SUPPLY

REDUNDANT "ON"

LEVEL

MOUNT FLOATLESS SWITCH

WITH (2) TIE STRAPS THAT

ARE PROVIDED WITH SWITCH.

PUMP PLUG

SWITCH PLUG

AUTOMATIC

OPERATION MANUAL

OPERATION

L1L2

SWITCH

DISCONNECT

WATERTIGHT

JUNCTION BOX

WHITE

BLACK

SEE CHART

BLACK

WHITE

WHITE

GREEN

BLACK

PUMP

FLOATLESS

SWITCH

SK3180

SYMPTOM POSSIBLE ROOT CAUSE POTENTIAL CORRECTIVE ACTION

A. Pump will not start or run.

Switch cord improperly plugged into receptacle Properly insert plug into receptacle

Pump cord improperly plugged into pump switch plug Properly insert pump cord into pump switch piggyback

plug

Blown panel fuse or breaker Replace with proper sized fuse or reset breaker

GFCI receptacle tripped Reset GFCI receptacle

Low voltage If voltage under 108 volts, contact qualied electrician

Main power outage The pump switch will not work without power

Contamination built-up on pump switch exterior See " Switch Maintenance" for proper cleaning

instructions

Improper mounting/ loose See "Installation Instructions"

Damaged or defective pump switch Contact Zoeller Product Support

B. Pump starts and stops too

often.

Signicant in-ow of water This is normal. Check pump specication to conrm

adequate pumping capacity

Pump switch mounted facing inlet pipe Reinstall switch facing away from inlet pipe

Defective check valve Replace the check valve

Excessive temperature Let system cool down for 5 minutes

Improper mounting/ loose See "Installation Instructions"

Damaged or defective pump switch Contact Zoeller Product Support

C.

Pump will not shut off when

water is not present at the

lower limit.

Contamination built-up on pump switch exterior See "Switch Maintenance" for proper cleaning

instructions

Improper mounting/ loose See "Installation Instructions"

Foreign conductive object near sensor Remove foreign object

Damaged or defective pump switch Contact Zoeller Product Support

TROUBLESHOOTING FOR FLOATLESS WATER LEVEL SWITCH

OPERATION:

1. Allow the sump to ll until the water level reaches the ON point.

2. Sump pump will turn on within 3 seconds of the water level reaching the ON point.

3. The pump will remain on until the water level drops below the OFF point. The pump may remain on up to 1 second after passing the

OFF point.

4. This will set the standard run time for the switch.

5. If the pump runs for longer than the standard run time, the standard run time will be incremented by 5 seconds on future cycles. This

will repeat until the run time is long enough for the water to reach the off level or the run time is increased to two minutes.

6. If water is over the "ON" level the pump will run continuously until the water is below the "ON" level, at which point the switch will revert

to standard operation.

MODEL NO. SUMP SEWAGE

X

10-4660 X

53-0084 X

98-0069 X

267-0121 X

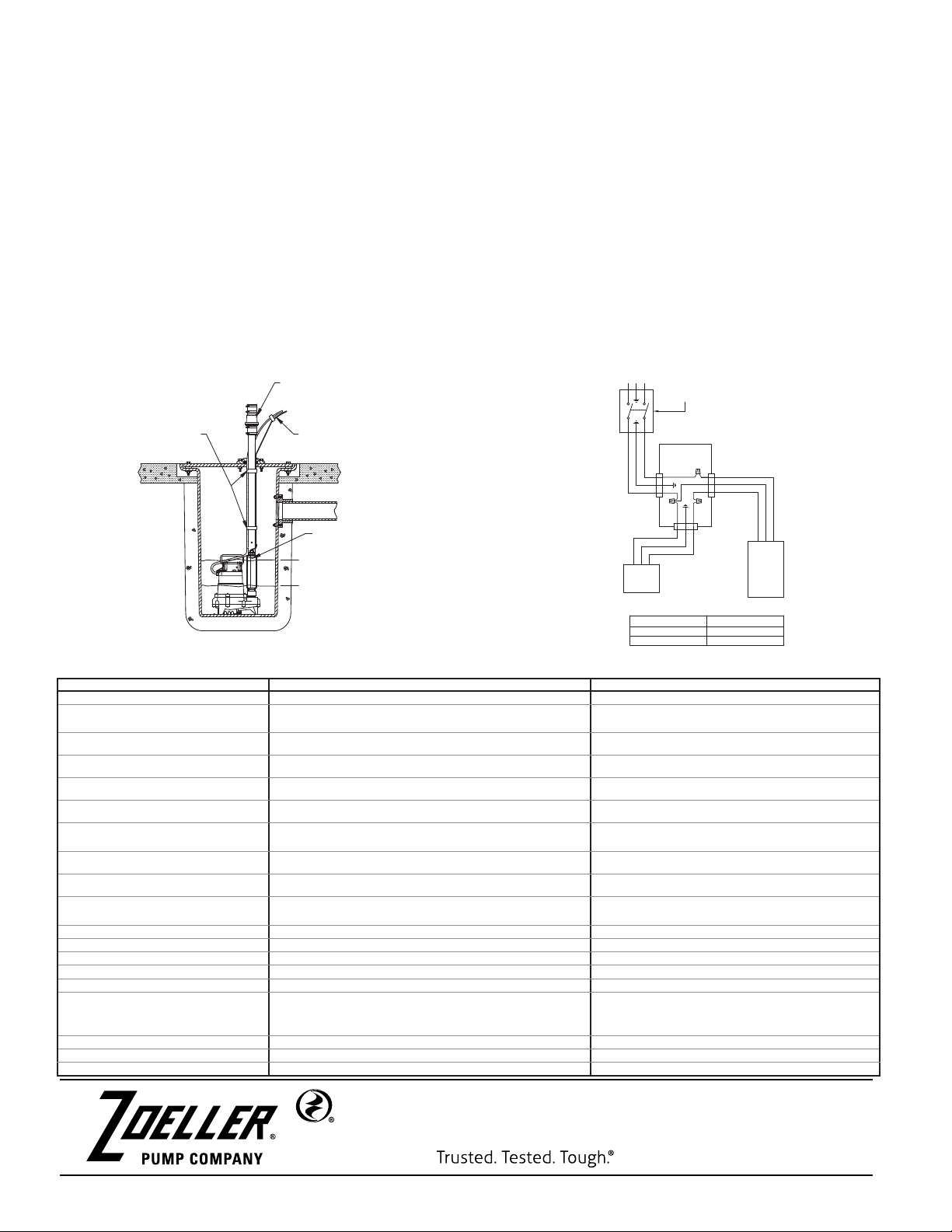

SWITCH TYPE POWER WIRE COLOR

SUMP RED

SEWAGE BLUE

DISCHARGE PIPE

CORDS SECURED TO

LEVEL

PUMP "OFF"

LEVEL

PUMP "ON"

ZOELLER UNICHECK

TO POWER SUPPLY

REDUNDANT "ON"

LEVEL

MOUNT FLOATLESS SWITCH

WITH (2) TIE STRAPS THAT

ARE PROVIDED WITH SWITCH.

PUMP PLUG

SWITCH PLUG

AUTOMATIC

OPERATION MANUAL

OPERATION

L1L2

SWITCH

DISCONNECT

WATERTIGHT

JUNCTION BOX

WHITE

BLACK

SEE CHART

BLACK

WHITE

WHITE

GREEN

BLACK

PUMP

FLOATLESS

SWITCH

FIGURE 4

For direct wire installations only

FLOATLESS SWITCH MAINTENANCE

Warning: Unplug Floatless switch and pump from all electrical power

BEFORE doing any service or maintenance.

• Inspect area around pump switch, wipe free of buildup and clear all

foreign objects.

• Plug pump switch and pump back into receptacle after inspection.

Check for proper operation.

• We recommend that you do this maintenance at least once a year.

However, harsh environmental conditions may dictate the frequency

of your actual maintenance schedule.

• Floatless pump switch contains NO serviceable parts.

Do not disassemble pump switch. Doing so can result

in death or electrical shock and voided warranty.

• If pump switch stops working, refer to

troubleshooting instructions provided.

• If part is under warranty, contact factory or sale

location.

• If part is not under warranty, the lawful disposal of

unit is necessary.