www.zookdisk.com

Serving America, Central & South America

16809 Park Circle Drive, Chagrin Falls,

Ohio 44022 USA

Toll Free: +1 800 543 1043

Phone: +1 440 543 1010

Serving Europe, Middle East & Africa

Navigation House, Bridge Street

Killamarsh, Sheffield,

S21 1AL UK

Phone: +44 (0) 1909 560999

E-mail: sales.europe@zookdisk.com

Serving Canada

4400 South Service Rd,

Burlington, Ontario L7L 5R8 CA

Toll Free: +1 800 370 6057

Phone: +1 905 681 2885

E-mail: sales.canada@zookdisk.com

Serving Asia Pacific

Unit No.23A-05, Menara Landmark, No.12,

Jalan Ngee Heng

80000 Johor Bahru, Johor, Malaysia

Phone: +60 (7) 2910099

E-mail: sales.asia@zookdisk.com

Page 2 of 4RT2_InstallationGuide_022219

Safety Through Knowledge and Performance

INSTALLATION INSTRUCTIONS

Graphite and Metal Rupture Disk Holders

Rupture Disk Series: RT2, RT2T, RE2, RE2T and Variants

INSTALLATION PROCEDURE

To achieve accurate burst pressures and a leak-free joint, several steps are required. It is imperative that a

proper bolt-up procedure is applied.

1) Inspect the Companion Flanges and Holder for cleanliness, damage and alignment:

a. Before installing the assembly into the system, ensure that the companion flange and holder

sealing surfaces are clean and free from all rust, corrosion, and foreign material. The allowable

imperfections in the flange gasket surface should not exceed the depth of the surface finish

grooves, and that the radial marks are no deeper than the depth of the flange surface finish and

less than 50% in length of the overall gasket sealing surface width.

b. To assure proper sealing of the assembly and flange gaskets parallelism, flatness, and waviness

should be within 0.008” (0.2mm) or less.

2) Check disk condition and specification prior to inserting the disk between the inlet and outlet insuring

that ALL FLOW ARROWS ARE POINTING IN THE PROPER DIRECTION. Do not lift the disk using

the disk tag – handle disk at the rim / edge.

WARNING: If the rupture disk is installed upside down, the burst pressure may exceed the marked

burst pressure. PAY CLOSE ATTENTION TO THE DIRECTIONAL ARROWS ON THE RUPTURE

DISK ASSEMBLY

3) Install new gaskets between the rupture disk assembly and the companion flanges. ZOOK

recommends compressed fiber gasket no greater than 1/8”. The user is cautioned to select a gasket

material that is suitable for the intended service and will resist “cold flow”. In the event of cold flowing

of the gaskets, the assembly torque will relax, which can result in erratic bursting of the rupture disk

and/or leakage.

4) Do not apply any compounds to the gasket or seating surfaces.

5) Reinstall companion flange studs and nuts, making sure they are free of any foreign matter, and

well lubricated. Lubricate the nut bearing surfaces as well. Lubrication is not required if PTFE coated

fasteners are used.

6) Run-up all nuts finger tight while maintaining parallelism

7) Determine the recommended bolting torque from Table 1.

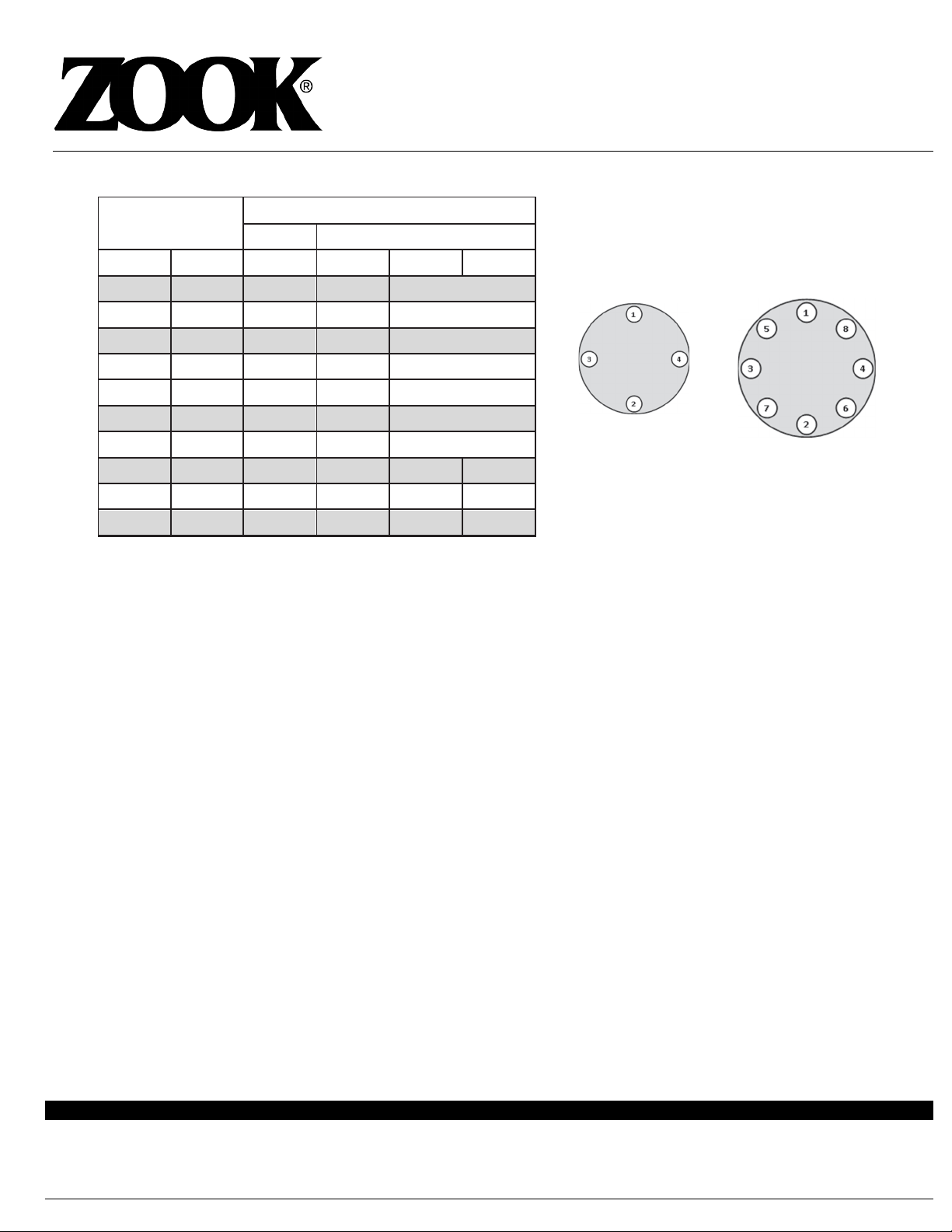

8) Using a calibrated torque wrench, apply torque incrementally in a minimum of three (3) passes

[30%, 60%, 100% of specified recommended torque] using a crossing pattern tightening sequence

(see diagrams below). After following this sequence, a final tightening should be performed using a

circumferential pattern moving bolt-to-bolt to ensure that all bolts have been evenly torqued.

9) Verify parallelism is in accordance with 1) a. above.

10) Torqueing loss is inherent in any bolted joint. The combined effects of bolt relaxation, gasket

creep, vibration in the system, thermal expansion and elastic interaction during bolt tightening

contribute to torque loss. Companion flange torque values should be verified periodically at the

system temperature.