7

13. Install the battery and receiver.

To prevent ejecting the battery in

flight, either put an extra security

strap around the canopy, or lock the

battery in place with glue or Velcro.

14. A good starting-point for the CG

is at the end of the center-rib, as

shown to the right. Advanced flyers

may want the CG 3- mm behind

this point. Add weights to the nose

or tail to balance.

Radio Setup

Small adjustments on your transmitter can significantly improve the handling of

your Zulu. Here are some recommendations to get started with:

Exponential, or Expo” makes small stick inputs less sensitive than large inputs.

The Zulu has large control surfaces that make it easy to over-control the aircraft.

0% expo for pitch and roll is a good starting-point.

Dual rates, will swap control deflections from full throw and some reduced travel

setting. On the Zulu, it works nicely to have a “regular flying mode”, where pitch

inputs are limited to ±1 °, and an unlimited setting for deep-stalls and aerobatic

maneuvers.

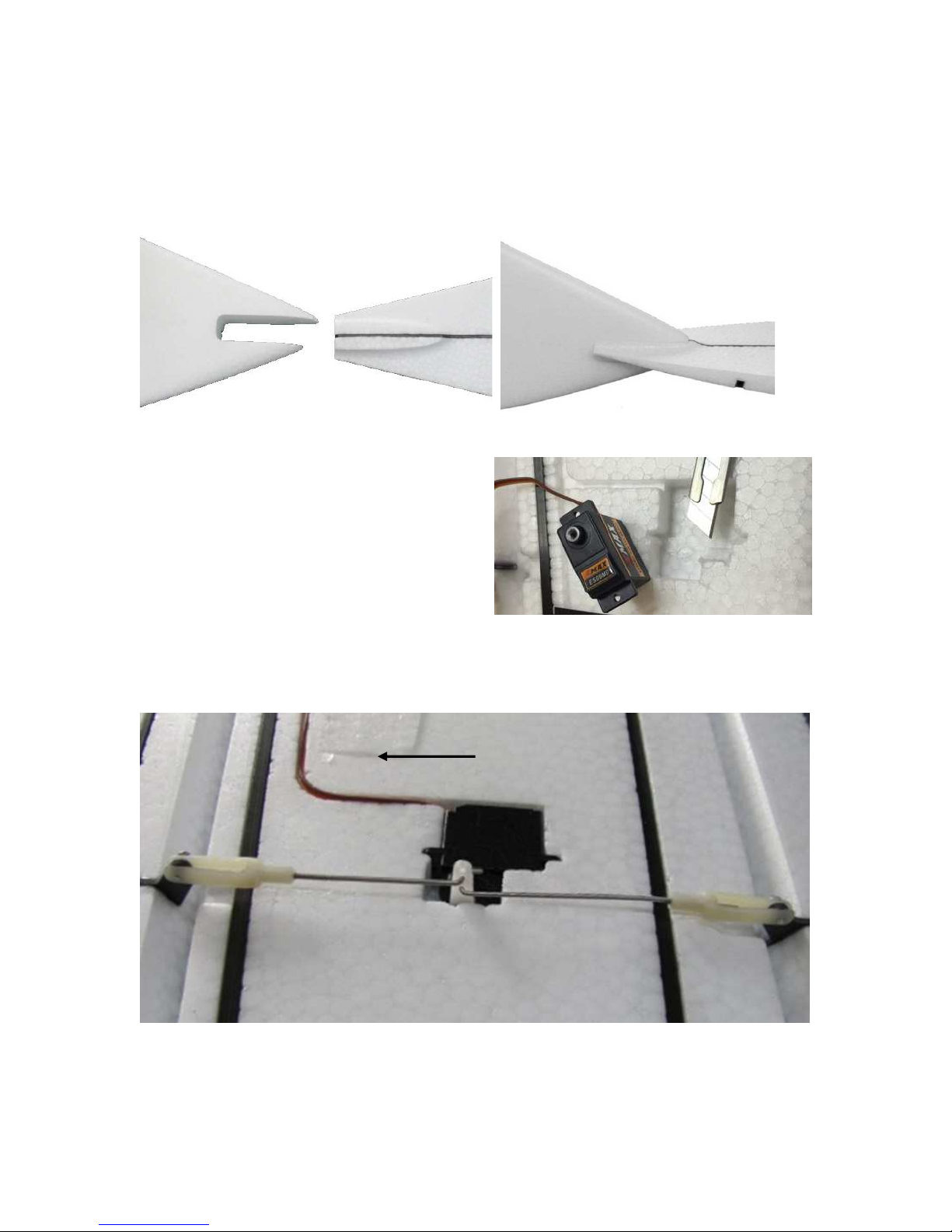

Aileron Differential is typically used on conventional aircraft to make the "up"

moving aileron move more than the "down" moving aileron. The Zulu rolls best if

the “up” and “down” moving elevons move about the same amount. You can

use the differential setting to tune this, and it typically requires a negative

differential value. If this option isn’t available on your transmitter, you can create

this effect mechanically:

1. Remove your servo arms and rotate them so they are angled back about 15°.

2. Reattach the servo arms and adjust the clevises (shorter in the rear, longer in the

front) to bring the control surfaces back to the trim settings.

Trimming

With the controls set to neutral, and rates set low, give the Zulu a toss on a lawn.

After trimming pitch and roll with your transmitter, adjust the drooperons back to

neutral (aligned with the fixed wing-tip) by twisting the clevises or bending the

pushrods.