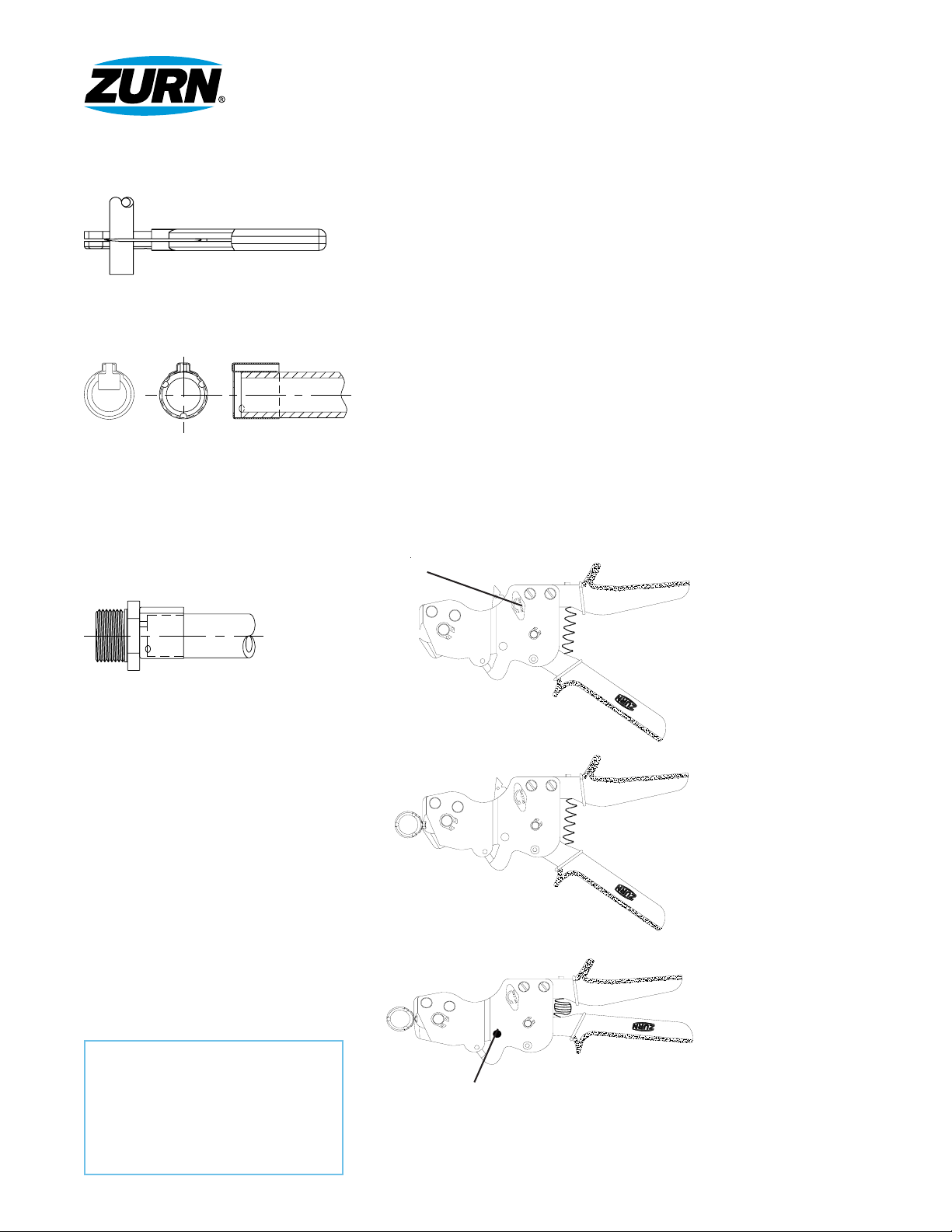

1. Cutting Zurn PEX®Tubing

Using a blade type cutter, cut

tubing to desired length.

2. Install QickClamp

Push tubing into the QickClamp

until the tubing stops and is visible

in the sight hole. Be sure that the

tab inside the QickClamp stays on

the outside of the tubing.

3. Install Fitting

Push tting into the tubing

until the tting shoulder touches

the QickClamp.

4. Crimp QickClamp

Open the QCRTQCRM tool by

turning the Release Knob counter-

clockwise (Figure 1). Place the jaws

completely over the QickClamp

pinch ear. With the tool at a 90°

angle to the tube (Figure 2), close

the tool by squeezing the handles

together repeatedly until the LED

light comes on. This may take 6-8

squeezes (Figure 3).

Important! Be sure the tool

jaws cover the entire ear of the

QickClamp before crimping;

failure to do so will result in an

improper crimp and may void

the warranty.

5. It is very important to complete the

crimping process before releasing

the tool. Open the QCRTQCRM

tool by turning the Release Knob

counter-clockwise. Visually verify

that a secure connection has

been made. If the entire ear did

not crimp, DO NOT recrimp. The

QickClamp must be cut out

and replaced.

OPERATION INSTRUCTIONS

Medium Ratcheting QickClamp®Tool

QCRTQCRM

Incorrect

Assembly

Correct

Assembly

Form No. ZPFN185 Date: 6/11/09

C.N. No.120064 Rev.

Medium Ratcheting QickClampTM Tool - QCRTQCRM

Operating Instructions

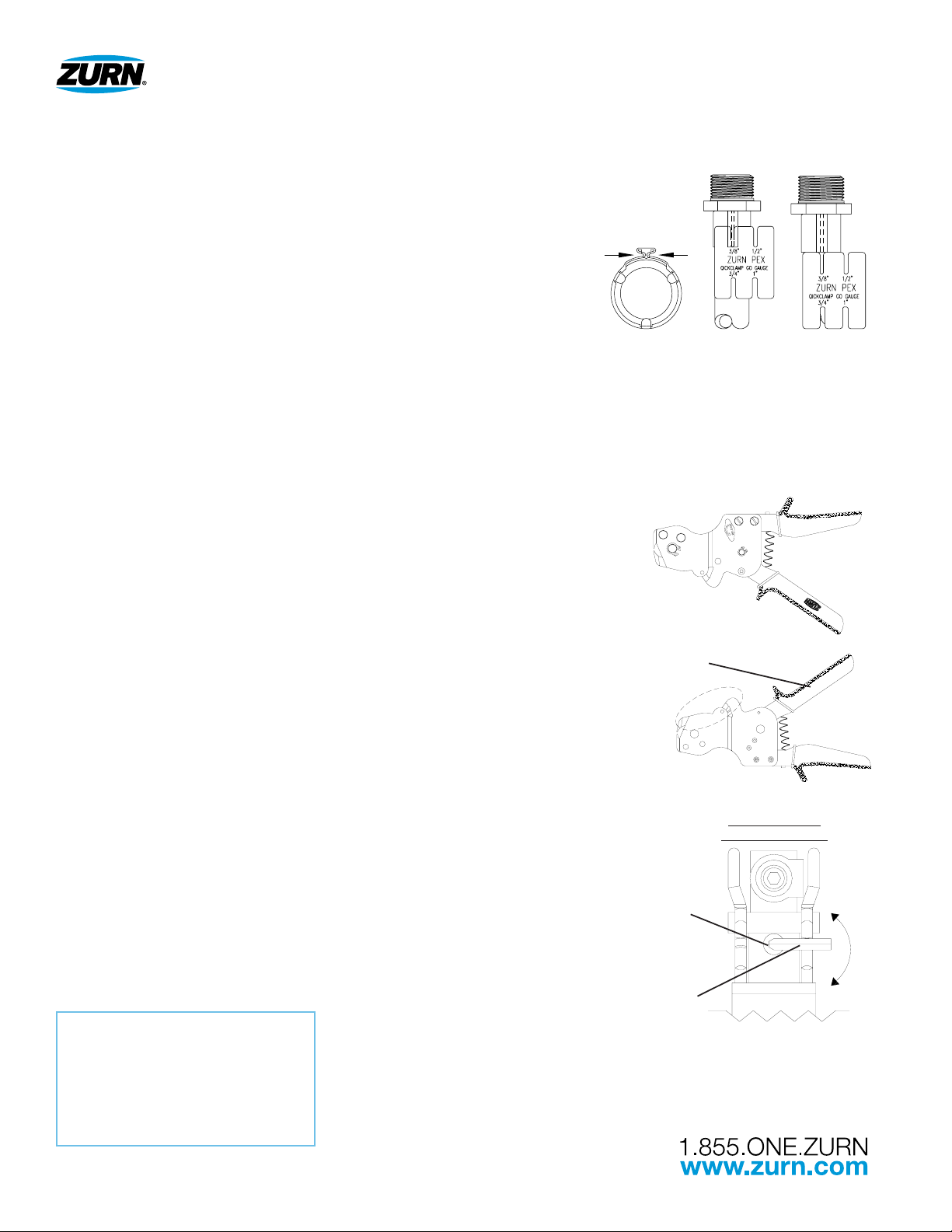

Step 4: Open the QCRTQCRM tool by turning the Release Knob

counter-clockwise (Figure 1). Place the jaws completely

over the QickClamp pinch ear. With the tool at a 90° angle

to the tube (Figure 2), close the tool by squeezing the

handles together repeatedly until the LED light comes on.

This may take 6-8 squeezes (Figure 3).

Important ! Be sure the tool jaws cover the entire ear

of the QickClamp before crimping; failure to do so will

result in an improper crimp and may void the war-

ranty.

Dimensional Data: Inches and [mm] are subject to manufacturing tolerances and change without notice.

Cutting Zurn PEX Tubing

Step 1: Using a blade type cutter, cut tubing to desired length.

Step 2: Push tubing into the QickClamp until the tubing stops and is

visible in the sight hole. Be sure that the tab inside the

QickClamp stays on the outside of the tubing.

Install QickClamp

Incorrect

Assembly

Correct

Assembly

Step 3: Push fitting into the tubing until the fitting shoulder touches

the QickClamp.

Install Fitting

Release

Knob

Figure 1

Figure 2

Figure 3

Crimp QickClamp

Step 5: It is very important to complete the crimping process

before releasing the tool. Open the QCRTQCRM tool by

turning the Release Knob counter-clockwise. Visually

verify that a secure connection has been made. If the

entire ear did not crimp, DO NOT recrimp. The QickClamp

must be cut out and replaced.

ZURN PEX

®

PLUMBING AND RADIANT HEATING SYSTEMS HWY 11 EAST, COMMERCE, TX, U.S.A. 75429 PHONE: 800/872-7277 FAX: 800/209-2148 WEBSITE: www.zurn.com

IN CANADA: ZURN INDUSTRIES LIMITED 3544 NASHUA DRIVE, MISSISSAUGA, ONTARIO L4V 1L2 PHONE: 905/405-8272 FAX: 905/405-1292

Form No. ZPFN185 Date: 6/11/09

C.N. No.120064 Rev.

Medium Ratcheting QickClampTM Tool - QCRTQCRM

Operating Instructions

Step 4: Open the QCRTQCRM tool by turning the Release Knob

counter-clockwise (Figure 1). Place the jaws completely

over the QickClamp pinch ear. With the tool at a 90° angle

to the tube (Figure 2), close the tool by squeezing the

handles together repeatedly until the LED light comes on.

This may take 6-8 squeezes (Figure 3).

Important ! Be sure the tool jaws cover the entire ear

of the QickClamp before crimping; failure to do so will

result in an improper crimp and may void the war-

ranty.

Dimensional Data: Inches and [mm] are subject to manufacturing tolerances and change without notice.

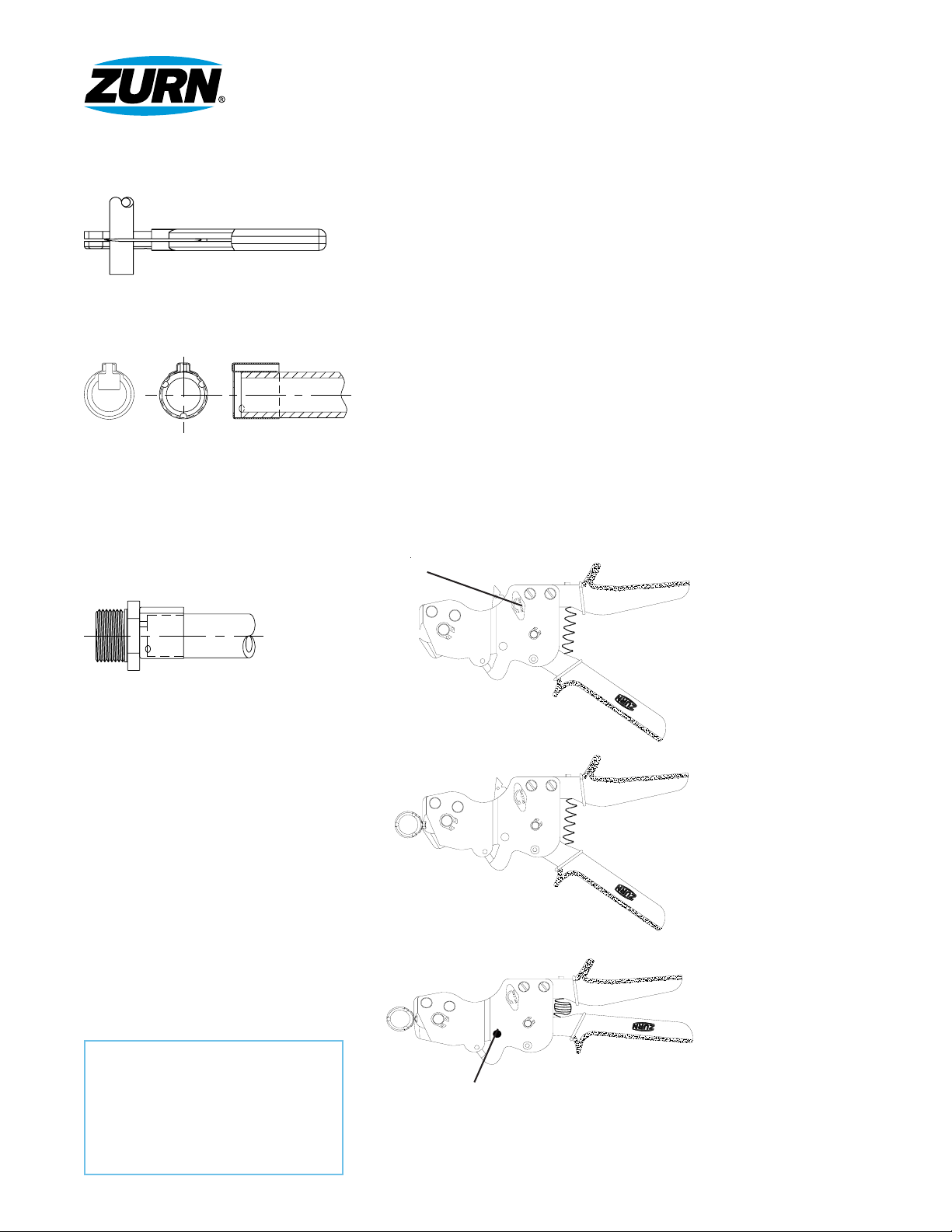

Cutting Zurn PEX Tubing

Step 1: Using a blade type cutter, cut tubing to desired length.

Step 2: Push tubing into the QickClamp until the tubing stops and is

visible in the sight hole. Be sure that the tab inside the

QickClamp stays on the outside of the tubing.

Install QickClamp

Incorrect

Assembly

Correct

Assembly

Step 3: Push fitting into the tubing until the fitting shoulder touches

the QickClamp.

Install Fitting

Release

Knob

LED Light

Figure 1

Figure 2

Figure 3

Crimp QickClamp

Step 5: It is very important to complete the crimping process

before releasing the tool. Open the QCRTQCRM tool by

turning the Release Knob counter-clockwise. Visually

verify that a secure connection has been made. If the

entire ear did not crimp, DO NOT recrimp. The QickClamp

must be cut out and replaced.

ZURN PEX

®

PLUMBING AND RADIANT HEATING SYSTEMS HWY 11 EAST, COMMERCE, TX, U.S.A. 75429 PHONE: 800/872-7277 FAX: 800/209-2148 WEBSITE: www.zurn.com

IN CANADA: ZURN INDUSTRIES LIMITED 3544 NASHUA DRIVE, MISSISSAUGA, ONTARIO L4V 1L2 PHONE: 905/405-8272 FAX: 905/405-1292

Form No. ZPFN185 Date: 6/11/09

C.N. No.120064 Rev.

Medium Ratcheting QickClampTM Tool - QCRTQCRM

Operating Instructions

Step 4: Open the QCRTQCRM tool by turning the Release Knob

counter-clockwise (Figure 1). Place the jaws completely

over the QickClamp pinch ear. With the tool at a 90° angle

to the tube (Figure 2), close the tool by squeezing the

handles together repeatedly until the LED light comes on.

This may take 6-8 squeezes (Figure 3).

Important ! Be sure the tool jaws cover the entire ear

of the QickClamp before crimping; failure to do so will

result in an improper crimp and may void the war-

ranty.

Dimensional Data: Inches and [mm] are subject to manufacturing tolerances and change without notice.

Cutting Zurn PEX Tubing

Step 1: Using a blade type cutter, cut tubing to desired length.

Step 2: Push tubing into the QickClamp until the tubing stops and is

visible in the sight hole. Be sure that the tab inside the

QickClamp stays on the outside of the tubing.

Install QickClamp

Incorrect

Assembly

Correct

Assembly

Step 3: Push fitting into the tubing until the fitting shoulder touches

the QickClamp.

Install Fitting

Release

Knob

LED Light

Figure 1

Figure 2

Figure 3

Crimp QickClamp

Step 5: It is very important to complete the crimping process

before releasing the tool. Open the QCRTQCRM tool by

turning the Release Knob counter-clockwise. Visually

verify that a secure connection has been made. If the

entire ear did not crimp, DO NOT recrimp. The QickClamp

must be cut out and replaced.

ZURN PEX

®

PLUMBING AND RADIANT HEATING SYSTEMS HWY 11 EAST, COMMERCE, TX, U.S.A. 75429 PHONE: 800/872-7277 FAX: 800/209-2148 WEBSITE: www.zurn.com

IN CANADA: ZURN INDUSTRIES LIMITED 3544 NASHUA DRIVE, MISSISSAUGA, ONTARIO L4V 1L2 PHONE: 905/405-8272 FAX: 905/405-1292

Note: Using this tool for anything other than its

intended use will void the warranty.

For troubleshooting and repair assistance,

do not return tool directly to wholesaler.

Call Zurn Customer Care for assistance

at 1-855-ONE-ZURN.

See www.zurn.com for warranty information.