TABLE OF CONTENTS

1.SAFETY INSTRUCTIONS .................................................................................................. 1

2. OVERVIEW..................................................................................................................9

2.1. FILAMENT MAKER FRONT VIEW ..................................................................... 9

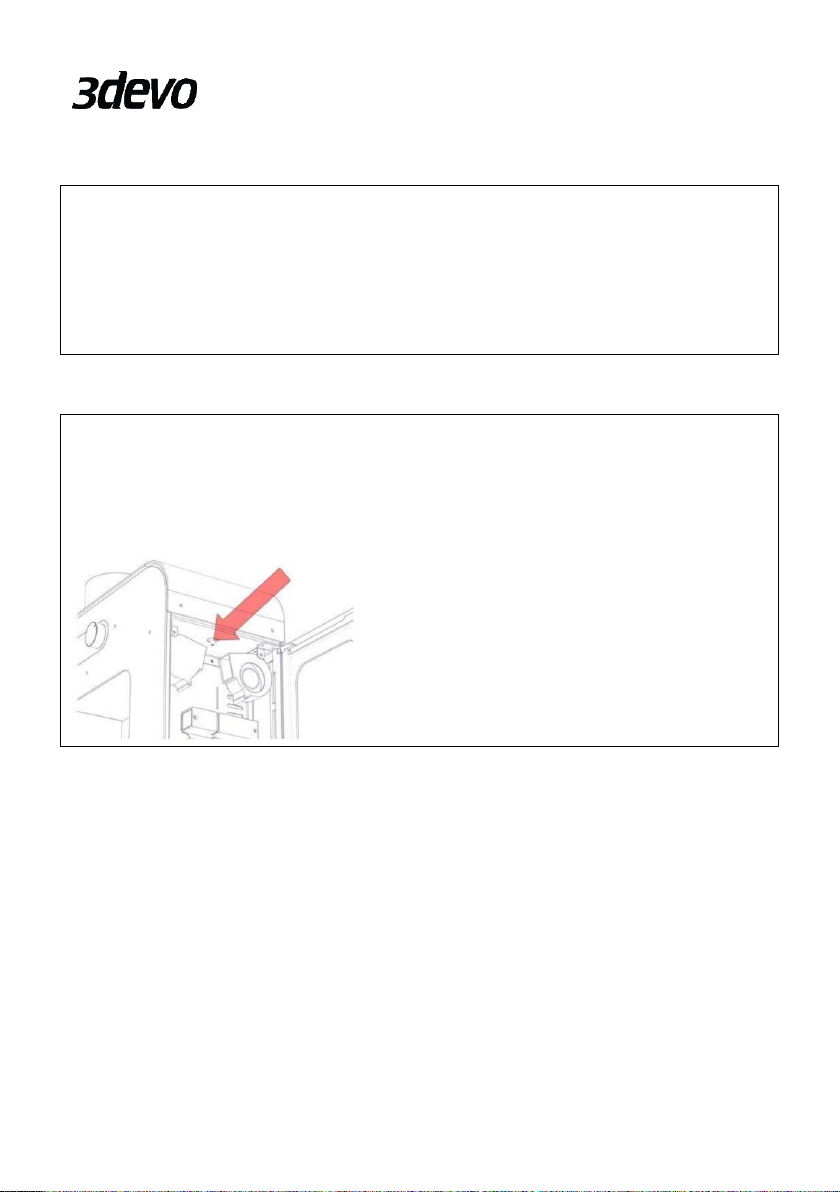

2.2. FILAMENT MAKER REAR VIEW ......................................................................10

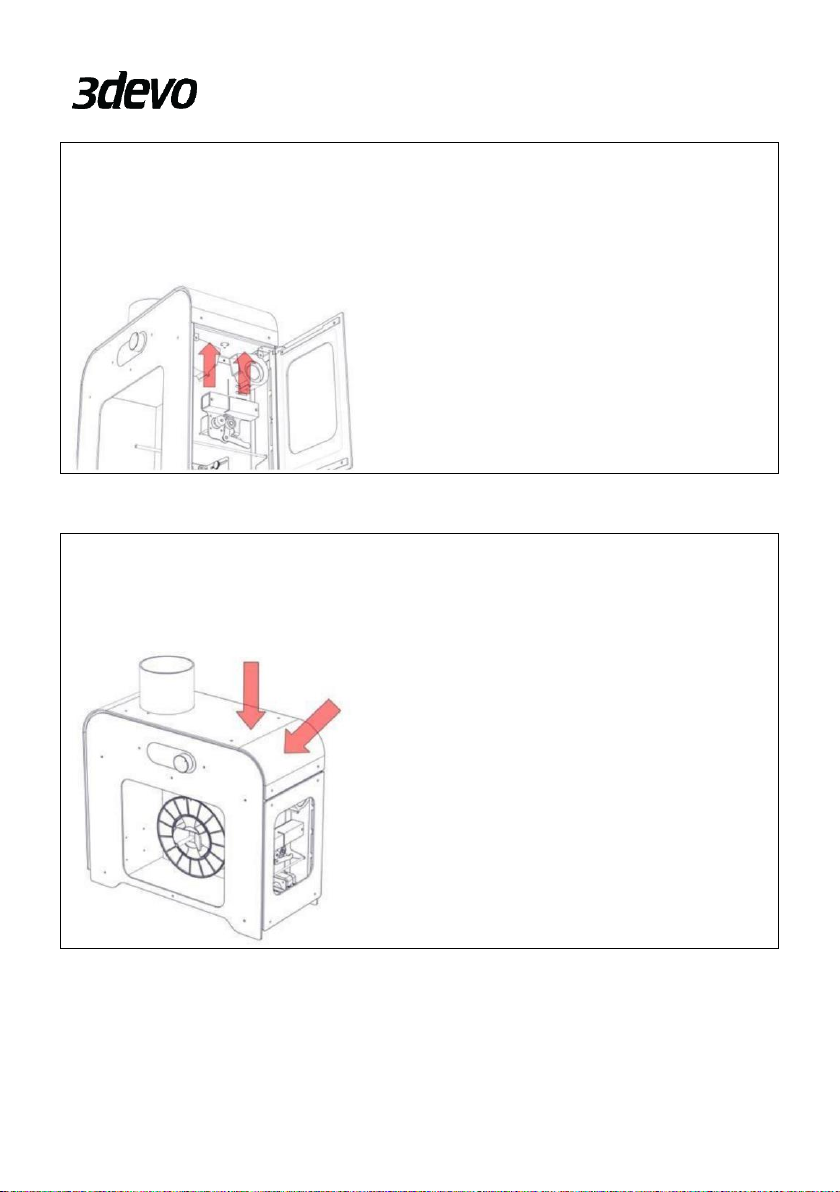

2.3. UNBOXING......................................................................................................11

2.4. ACCESSORIES .................................................................................................12

2.5. QUICK START GUIDE......................................................................................13

2.6. TECHNICAL SPECIFICATIONS........................................................................13

3. INSTALLATION.........................................................................................................14

4. USER INTERFACE .....................................................................................................15

4.1. STATUS SCREEN .............................................................................................16

4.2. STATUS INDICATORS .....................................................................................16

4.3. STATUS TYPES ................................................................................................18

4.4. MAIN MENU....................................................................................................19

4.5. START EXTRUSION AUTOMATICALLY (RECOMMENDED) ..........................19

4.6. START EXTRUSION MANUALLY ....................................................................19

4.7. SETTINGS ........................................................................................................21

4.8. MATERIAL PRESETS........................................................................................22

4.9. SPOOLING –IDLE...........................................................................................23

4.10. ABOUT THIS MACHINE..................................................................................24

4.11. RUNNING MENU............................................................................................24

4.12. SPEED TUNING...............................................................................................25

4.13. SPOOLING MENU –RUNNING .....................................................................26

4.14. SOFTWARE ERRORS .......................................................................................27