2

WRINKLES

Your Yak 54 was packed in plastic at the factory without any wrinkles in the covering. You may notice

some wrinkles now; more likely, you will notice a few in a day or two or the first time you take the plane

out to the flying field. These wrinkles are the result of wood shrinkage and/or expansion. Balsa wood

changes size and shape slightly as it is exposed to varying humidity in the air. This is a natural property

of balsa wood. As your airplane adjusts to the weather in your part of the world, wrinkles may appear and

disappear.

Wrinkles may be removed with the gentle application of heat to the covering material on your airplane.

The best tool to use is a heat gun. Apply the heat gently: the covering material will shrink as you apply

the heat, and this will remove the wrinkles. BE CAREFUL! Too much heat applied too quickly can

damage the covering, either by causing it to pull away from the wood at seams and corners or even by

melting it. The covering will shrink at low temperature with patient application of heat. Wrinkles do not

affect flight performance.

WING ASSEMBLY

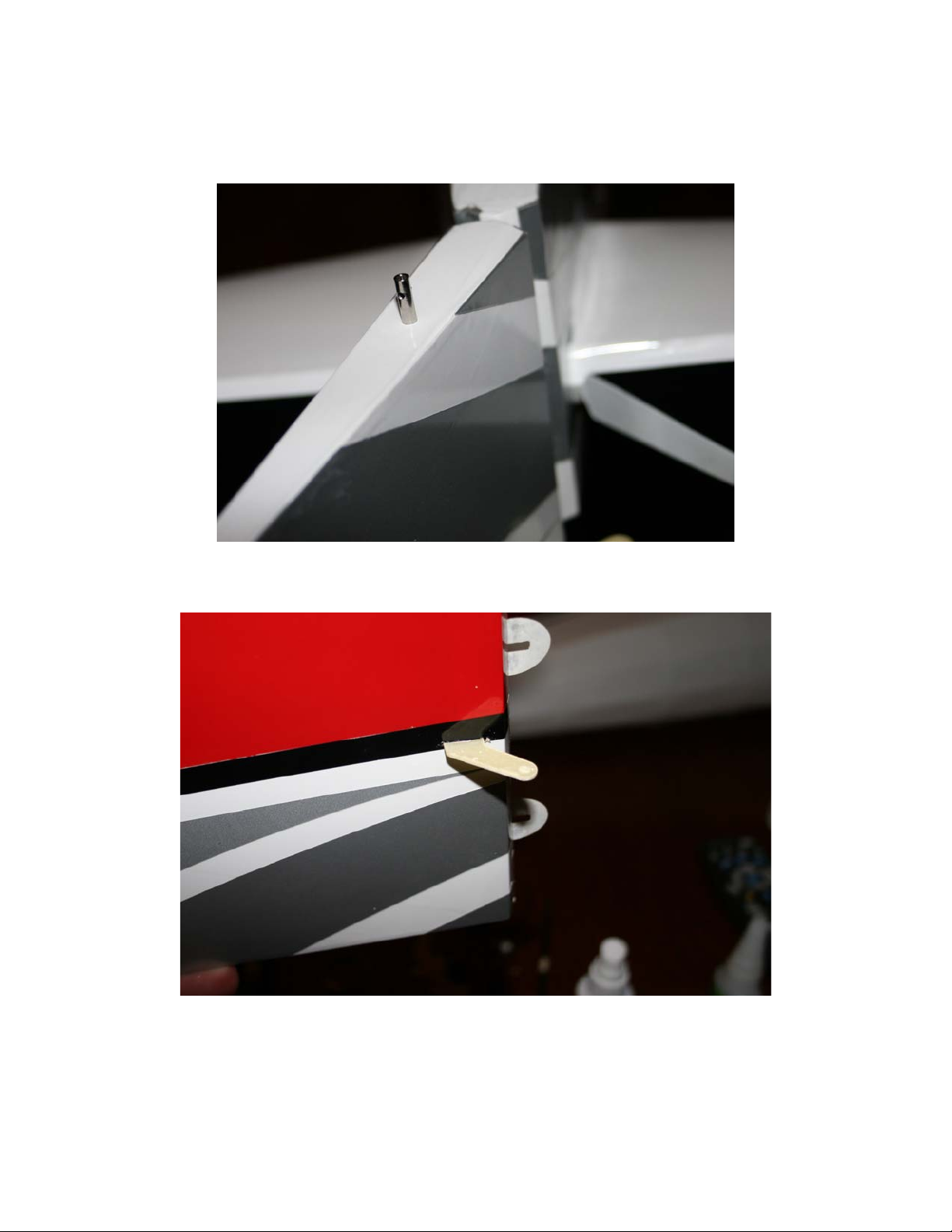

The ailerons hinge onto the wings using 4 hinges each. The hinges are already installed into the wings,

but need to be glued with THIN CA glue. Check the fit of the aileron to be sure the color stripes line up on

the wing, and flex the aileron to be sure that it moves freely and the hinges flex easily. Drip two large

drops of THIN CA glue into the aileron hinge joint right on top of each hinge. The THIN CA glue will wick

into the hinge slots and penetrate the wood, forming a strong hinge joint. Use two large drops per hinge,

no less. After the ailerons are hinged, install the supplied wing decal as shown.

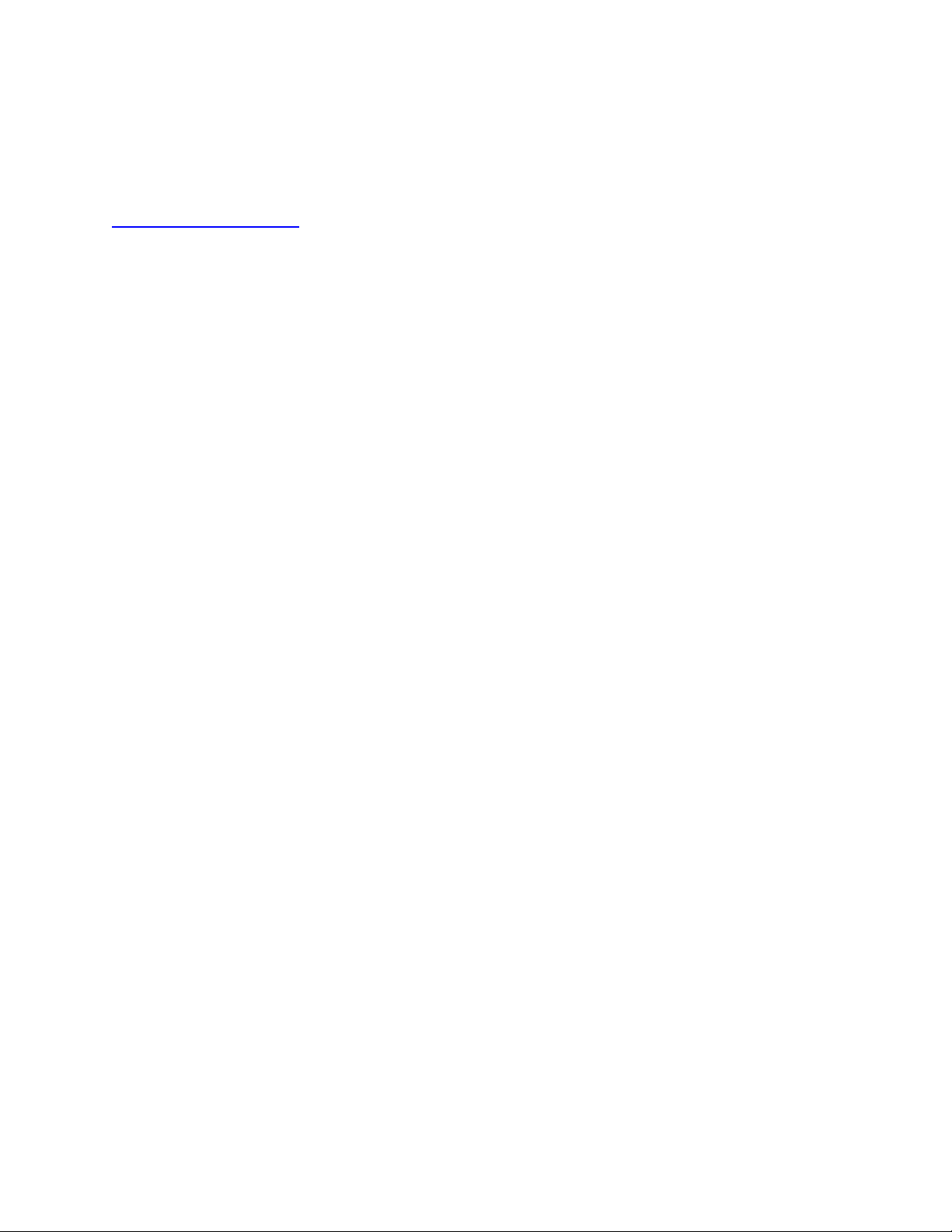

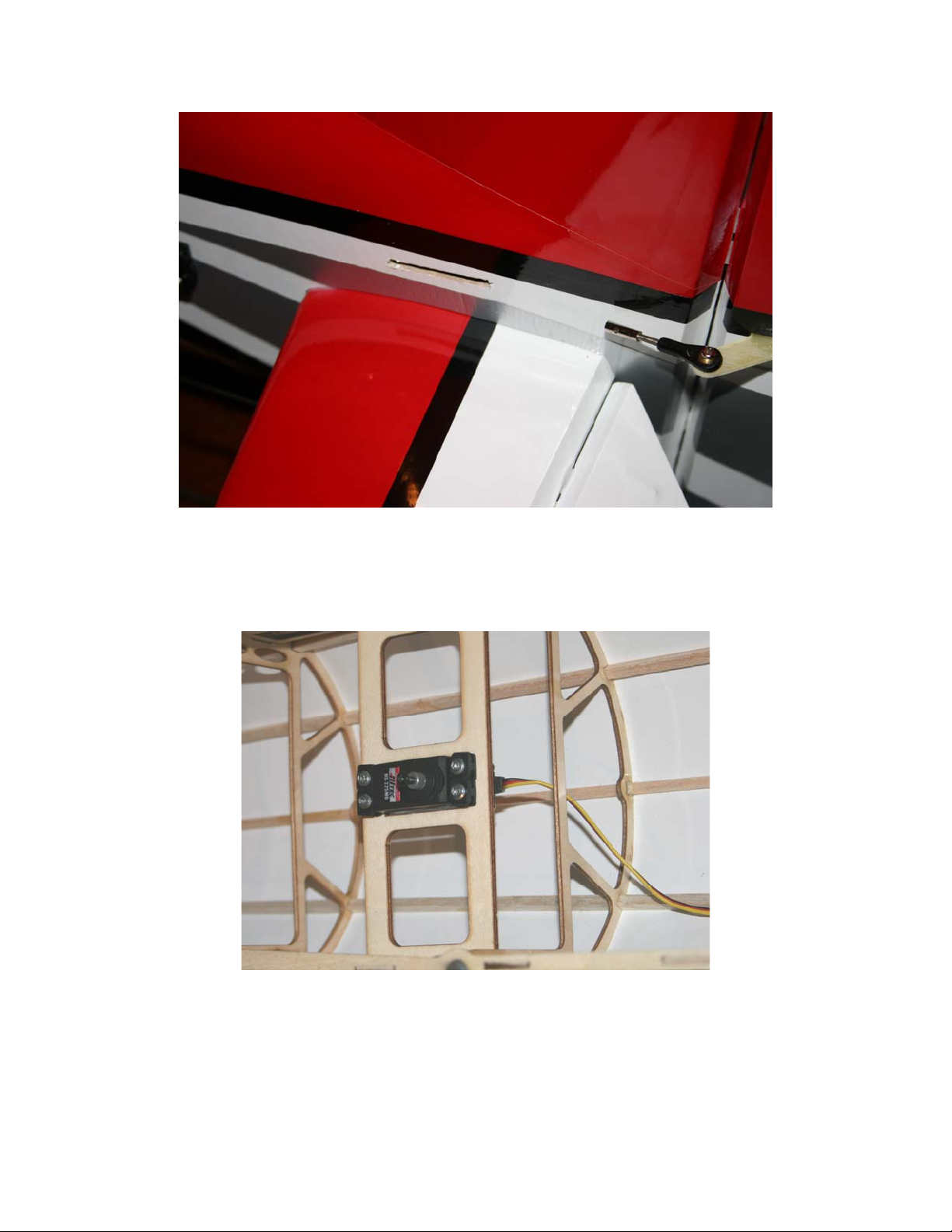

Locate the aileron servo mount on the bottom of the wing and remove the covering over the hole. The

best way to remove covering on this airplane is with a hot soldering iron tip, as this seals the edge of the

cut. However, you can also use your hobby knife to remove the covering. Also remove the covering over

the control horn slot in the position shown.