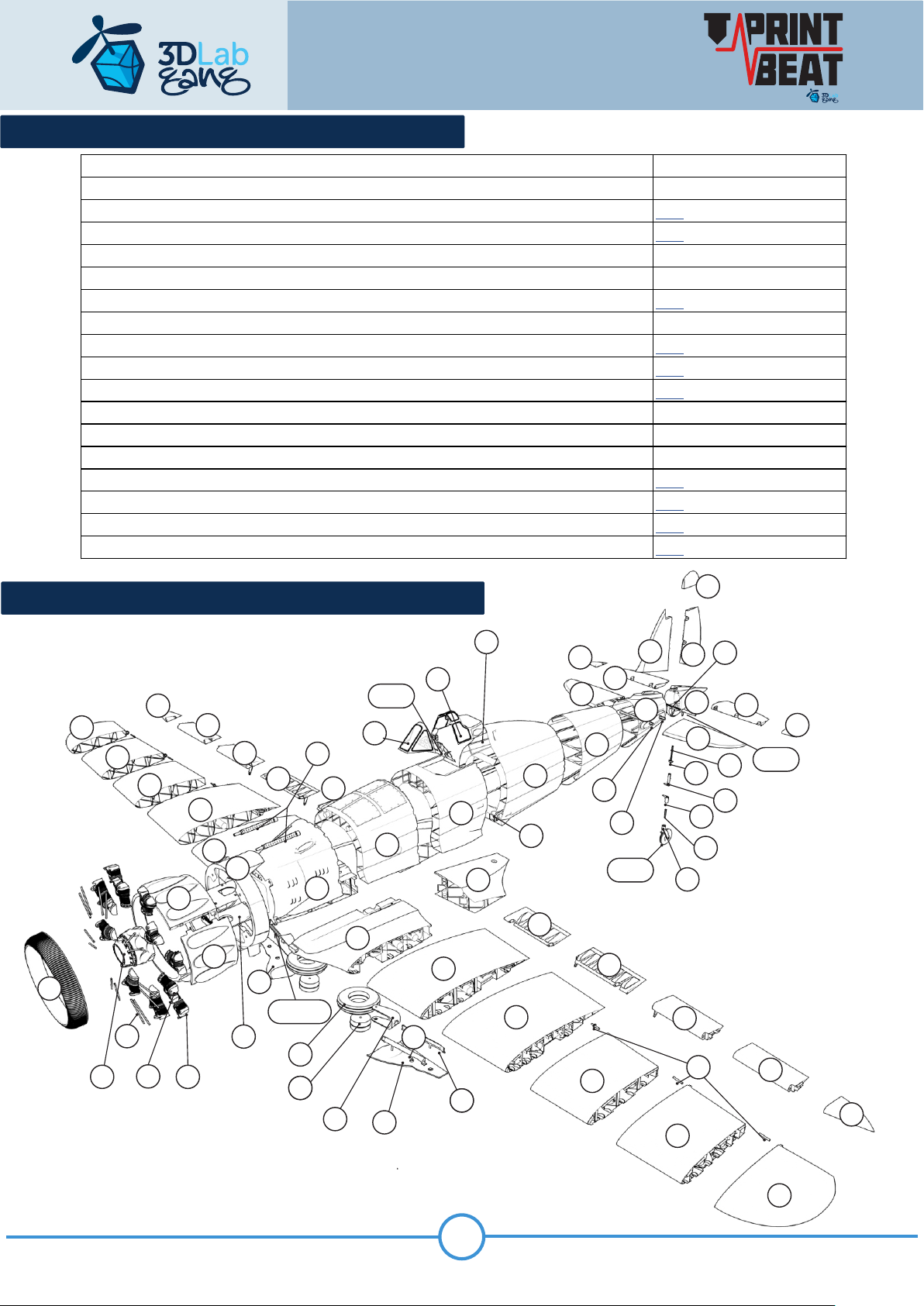

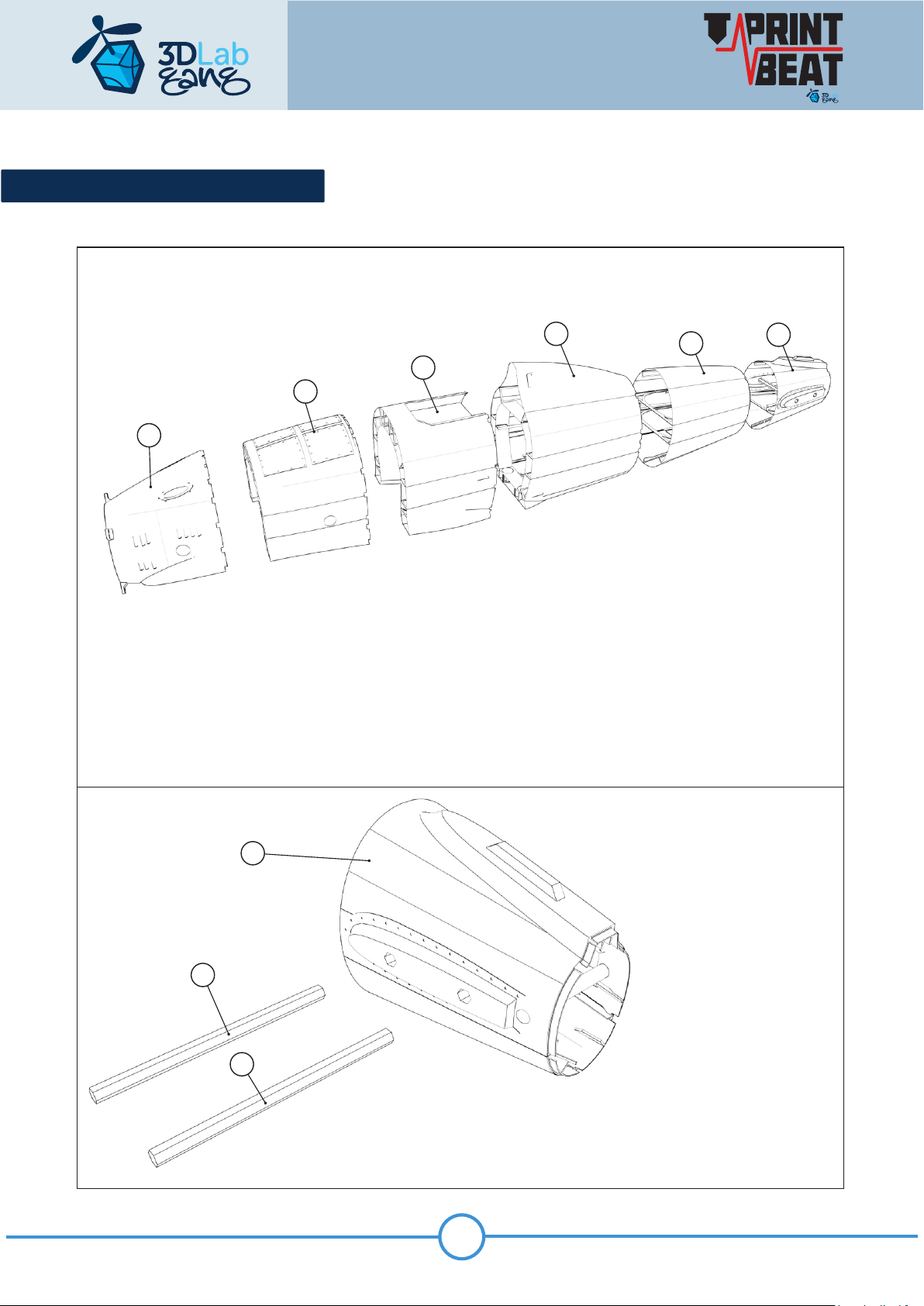

44 Ring 0,25mm 29g 0% no 0,9 1 Engine_40_-_49

45 Motor Body 0,25mm 8g 0% no 0,84 1 Engine_40_-_49

46 Cylinder Front 0,25mm 2g 0% no 0,84 2 Engine_40_-_49

47 Cylinder Back 0,25mm 2g 0% no 0,84 2 Engine_40_-_49

48 OHV Timing Rod 0,25mm 1g 0% no 0,9 1 Engine_40_-_49

49 Exhaust 0,25mm 1g 0% no 0,9 1 Engine_40_-_49

50 Wing Left A 0,19mm 48g 0% no 0,86 1 Wing_50_-_74

51 Wing Left B 0,19mm 25g 0% no 0,86 1 Wing_50_-_74

52 Wing Left C 0,25mm 60g 0% no 0,89 1 Wing_50_-_74

53 Wing Left D 0,25mm 49g 0% no 0,86 1 Wing_50_-_74

54 Wing Left E 0,25mm 26g 0% no 0,86 1 Wing_50_-_74

55 Wing Left F 0,25mm 23g 0% no 0,86 1 Wing_50_-_74

56 Wing Left G 0,25mm 16g 0% no 0,86 1 Wing_50_-_74

57 Landing Flaps Left A 0,25mm 0g 0% no 0,85 1 Wing_50_-_74

58 Landing Flaps Left B 0,25mm 0g 0% no 0,85 1 Wing_50_-_74

59 Ailerons Left A 0,25mm 0g 0% no 0,85 1 Wing_50_-_74

60 Ailerons Left B 0,25mm 0g 20% no 0,85 3 Wing_50_-_74

61 Ailerons Left C 0,25mm 0g 20% no 0,85 3 Wing_50_-_74

62 Wing Right A 0,25mm 48g 20% no 0,85 3 Wing_50_-_74

63 Wing Right B 0,25mm 25g 20% no 0,86 3 Wing_50_-_74

64 Wing Right C 0,25mm 60g 15% no 0,86 3 Wing_50_-_74

65 Wing Right D 0,25mm 49g 15% no 0,86 3 Wing_50_-_74

66 Wing Right E 0,25mm 26g 15% no 0,86 3 Wing_50_-_74

67 Wing Right F 0,25mm 23g 15% no 0,86 3 Wing_50_-_74

68 Wing Right G 0,25mm 16g 0% no 0,86 1 Wing_50_-_74

69 Landing Flaps Right A 0,25mm 0g 0% no 0,85 1 Wing_50_-_74

70 Landing Flaps Right B 0,25mm 0g 0% no 0,85 1 Wing_50_-_74

71 Ailerons Right A 0,25mm 0g 0% no 0,85 1 Wing_50_-_74

72 Ailerons Right B 0,25mm 0g 0% no 0,85 3 Wing_50_-_74

73 Ailerons Right C 0,25mm 0g 10% no 0,85 1 Wing_50_-_74

74 Wing Hex 0,25mm 0g 0% no 0,95 1 Wing_50_-_74

75 Retraction Gear Leg Left A 0,15mm 5g 100% no 0,92 10 Landing_gear_75_-_84

76 Retraction Gear Leg Left B 0,15mm 5g 100% no 0,92 10 Landing_gear_75_-_84

77 Retraction Gear Fork Left 0,20mm 7g 100% no 0,92 10 Landing_gear_75_-_84

78 Retraction Gear Cover Left 0,25mm 6g 0% no 0,85 1 Landing_gear_75_-_84

79 Retraction Gear Leg Right A 0,15mm 5g 100% no 0,92 10 Landing_gear_75_-_84

80 Retraction Gear Leg Right B 0,15mm 5g 100% no 0,92 10 Landing_gear_75_-_84

81 Retraction Gear Fork Right 0,20mm 7g 100% no 0,92 10 Landing_gear_75_-_84

82 Retraction Gear Cover Right 0,25mm 6g 0% no 0,85 1 Landing_gear_75_-_84

83 Wheal 0,25mm 17g 0% no 1,04 3 Landing_gear_75_-_84

84 Disc 0,25mm 6g 7% no 0,92 2 Landing_gear_75_-_84

85 Ailerons Axe 0,25mm 1 100% no 0,92 2

86 Washer 0,25mm 1 100% no 2