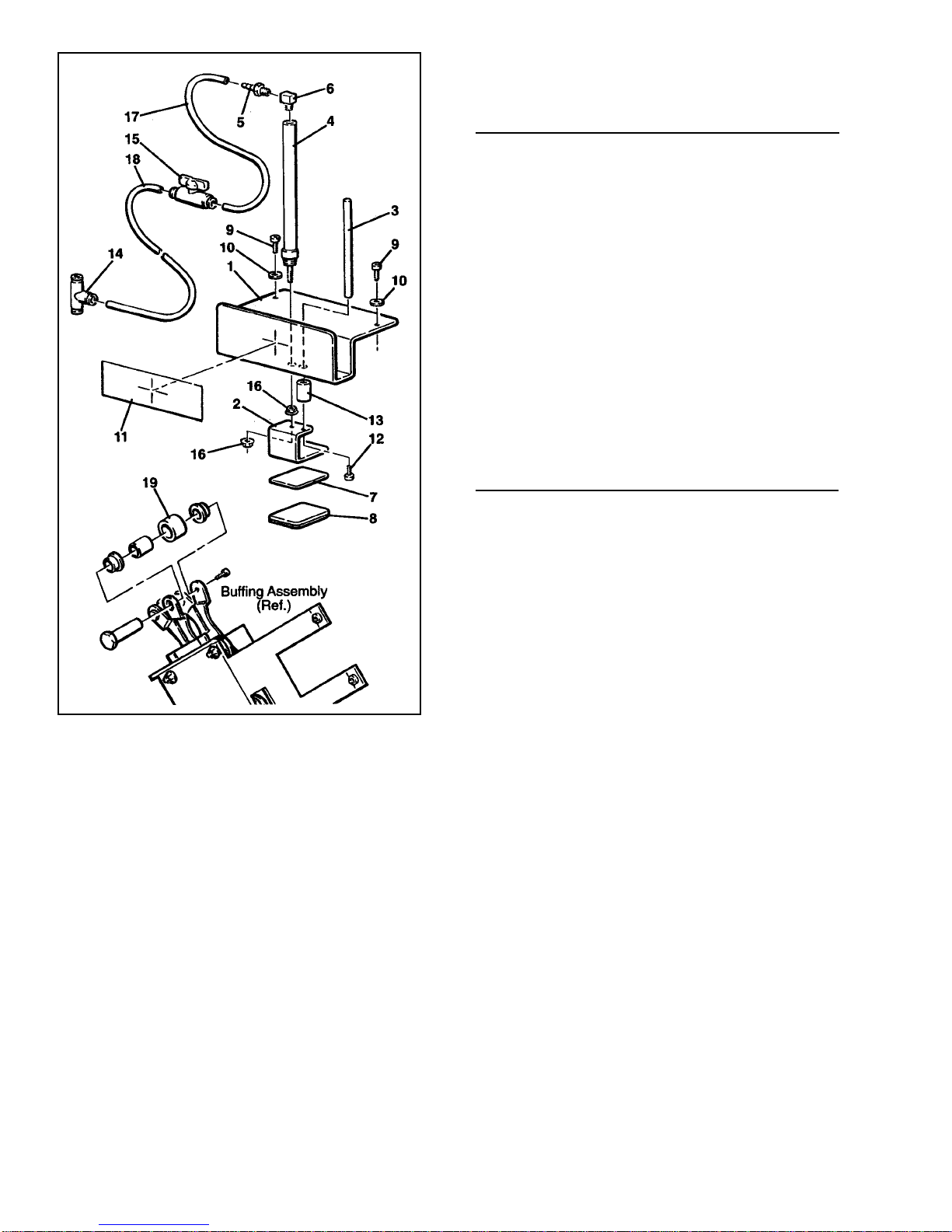

Ref. Part

No. Number Description Qty.

1 78-8119-6882-1 Bracket, Mounting 1

2 78-8119-6883-9 Bracket, Buffing 1

3 78-8119-6884-7 Shaft 1

4 26-1014-4181-9 Cylinder, Air, 7/16" Bore, 1

Bimba #013-NR

5 26-1014-4182-7 Fitting, Barbed, #10-32, 1

Bimba #D-3229-A

6 26-1014-6599-0 Fitting, Street Ell, #10-32 1

7 78-8119-6919-1 Pad, Buffing, Upper 1

8 78-8119-6918-3 Buffing Pad Assembly, Lower 1

9 26-1004-6031-5 Screw, Cap, Soc Hd, 10-24 x 1/2 Lg. 2

10 26-1000-4442-4 Washer, Plain, Type A, #10 2

11 78-8119-6594-2 Label, Warning, Sharp Knife Rollers 1

12 18-3172-8216-0 Screw, Cap, Soc Hd, 8-32 x 1/2 Lg. 1

13 78-8119-6935-7 Stop, Buffer 1

14 26-1014-6602-2 Tee, Union, 1/4 Polyflo

Legris #3104-56-00 1

15 26-1014-6963-8 Valve, Ball, 1/4-1/4 Polyflo

Pisco #BVU20-1/4-1/4 1

16 26-1014-6970-3 Nut, Hex Flange, 10-32 2

17 78-8119-6936-5 Tube, Poly-Flo, 8.5 In. Lg. 1

18 78-8122-6541-7 Tube, Poly-Flo, 32.5 In. Lg. 1

19 78-8122-6664-7 Buffing Sleeve 1

Replacement Parts List

Figure 7—Replacement Parts Illustration

3M Industrial Adhesives and Tapes Division

3M Center, Building 220-4E-01

St. Paul, MN 55144-1000

“3M-Matic” is a trademark of 3M,

St. Paul, Minnesota 55144-1000

Printed in U.S.A.

© 3M 2007 44-0009-1957-9(C)

How To Order Replacement Parts

1. Refer to Parts Illustration Figure 7 to find part needed

and reference number.

2. Refer to parts list for correct part number.

3. Order by part number, description, kit name, and kit

part number.

4. Replacement parts and part prices available direct

from:

3M/Tape Dispenser Parts

241 Venture Drive

Amery, WI 54001-1325

Minimum billing on parts orders will be $25.00.

Replacement part prices available on request. $10.00

restocking charge per invoice on returned parts.

Outside the U.S., contact the local 3M subsidiary for

parts information.

800-344-9883

Fax: 715-268-8153

33

33

3

EquipmentWarrantyandLimitedRemedy:THEFOLLOWINGWARRANTY ISMADEINLIEUOFALL OTHERWARRANTIES,EXPRESS

ORIMPLIED,INCLUDING,BUTNOTLIMITEDTO,ANYIMPLIEDWARRANTYOFMERCHANTABILITYORFITNESSFORAPARTICULAR

PURPOSEANDANYIMPLIEDWARRANTY ARISING OUT OF A COURSE OF DEALING, CUSTOMORUSAGEOFTRADE:

3M sells its 3M-Matic™ P/N 70-0708-6798 S867/S857 U-Clip Modification Kit with the following warranties:

Limitation of Liability: Except where prohibited by law, 3M and seller will not be liable for any loss or damage arising from this 3M equipment, whether direct,

indirect, special, incidental, orconsequential, regardless of the legal theoryasserted, including breach of warranty, breach ofcontract, negligence, or strict liability.

Note: The foregoing Equipment Warranty and Limited Remedy and Limitation of Liability may be changed only by a written agreement signed by authorized

representatives of 3M and seller.

All parts will be free from defects in material and manufacture for ninety (90) days after delivery.

If any part is defective within this warranty period, your exclusive remedy and 3M’s and seller’s sole obligation shall be, at 3M’s option, to repair or replace

the part. 3M must receive actual notice of any alleged defect within a reasonable time after it is discovered, but in no event shall 3M have any obligation

under this warranty unless it receives such notice within five (5) business days after the expiration of the warranty period. All notices required hereunder

shall be given to 3M solely through the 3M-Matic™ Helpline (800-328-1390). To be entitled to repair or replacement as provided under this warranty, the part

must be returned as directed by 3M to its factory or other authorized service station designated by 3M. If 3M is unable to repair or replace the part within

a reasonable time after receipt thereof, 3M, at its option, will replace the equipment or refund the purchase price. 3M shall have no obligation to provide or

pay for the labor required to remove any part or equipment or to install the repaired or replacement part or equipment. 3M shall have no obligation to repair

orreplacethose parts failing due to normal wear, inadequateor improper maintenance, inadequatecleaning, non-lubrication, improper operating environment,

improper utilities, operator error or misuse, alteration or modification, mishandling, lack of reasonable care, or due to any accidental cause.