5

(208-DG SEALS)

OPERATING INSTRUCTIONS FOR USE WITH 208-DG SEALS

Wear safety glasses which conform to ANSI Standard Z87.1 or EN 166. Stand to one side of

the tensioned strap while sealing. Maintain proper footing and balance. Make sure all

bystanders are clear before proceeding.

When using a 208-DG seal, two crimping

operations are required for each seal.

1. Thread two (2) seals onto the strap.

2. Fully open sealer handles and place the

open jaws to one end of the first seal.

3. Bring sealer handles completely together

to assure a proper crimp.

place the sealer on the opposite end of

the seal and bring the handles completely

together.

5. Repeat steps 2 and 3 for the second seal.

6. Inspect strap joint for proper formation,

see Joint Inspection. Cut the strap off by

bending the strap back and forth until it

breaks of flush with the seal.

7. To avoid contact with sharp end of strap,

retract strap end back into strap

dispenser.

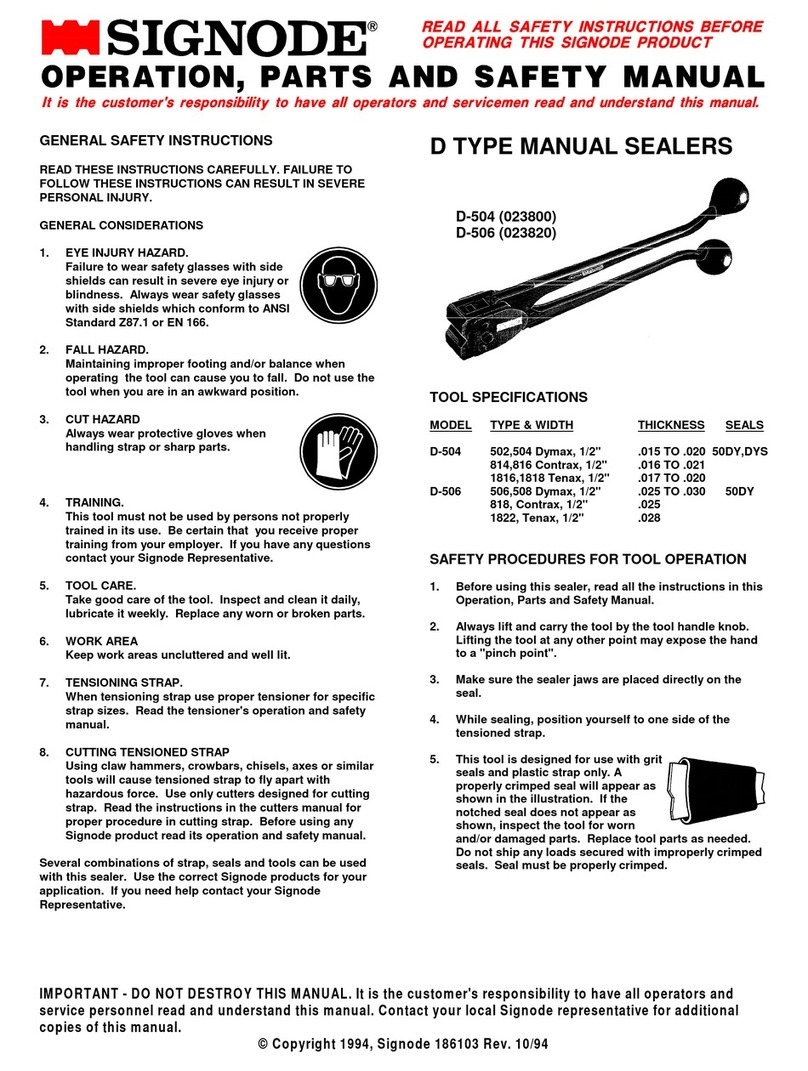

JOINT INSPECTION, 208-DG SEAL

This tool is a single crimp type sealer that

requires two (2) seals and two (2) sealing

operations for each seal. Properly crimped

seals will appear as shown in the illustration.

If the crimped seals do not appear as shown,

then the operator must proceed as follows:

A. E

nsure that the tool's operating

instructions are being followed before

applying another strap.

B. Cut the strap off and apply another.

If the crimped seals still do not appear as

shown, then inspect the tool for worn and/or

damaged parts. Replace tool parts as

needed. BEFORE MOVING ANY PACKAGE

BE CERTAIN THAT THE SEALS ARE

PROPERLY CRIMPED AS SHOWN.

Miscrimped joints may not secure the load

and could cause serious injury.