2

Important Safeguards

This safety alert symbol identifies

important messages in this

manual. READ AND UNDERSTAND

THEM BEFORE INSTALLING OR

OPERATING THIS EQUIPMENT.

Explanation of Signal Word Consequences

Indicatesapotentiallyhazardous

situation,which,ifnotavoided,

could result in death or serious

injuryand/orpropertydamage.

WARNING:

Indicatesapotentiallyhazardous

situation,which,ifnotavoided,

may result in minor or moderate

injuryand/orpropertydamage.

CAUTION:

•To reduce the risk associated with sharp

blade hazards:

−Keephandsandfingersawayfromtapecutoff

bladesunderorangebladeguards.The

bladesareextremelysharp

•To reduce the risk associated with muscle

strain:

−Usetheappropriateriggingandmaterial

handlingequipmentwhen liftingor

repositioningthisequipment

WARNING (continued)

•To reduce the risk associated with pinch

and entanglement hazards:

−Always feed boxes into the machine by

pushing only from the end of the box

−Keephands,hair, loose clothing, and jewelry

awayfromopening in the nest

CAUTION

•To reduce the risk associated with

mechanical and pneumatic hazards:

−Read,understandandfollowallsafetyand

operatinginstructionsbeforeoperatingor

servicingthecasesealer

−Allowonlyproperlytrainedandqualified

personneltooperateand/orservicethis

equipment

−Neverattempttodefeatthemachineguard

interlock

•To reduce the risk associated with pinch

and entanglement hazards:

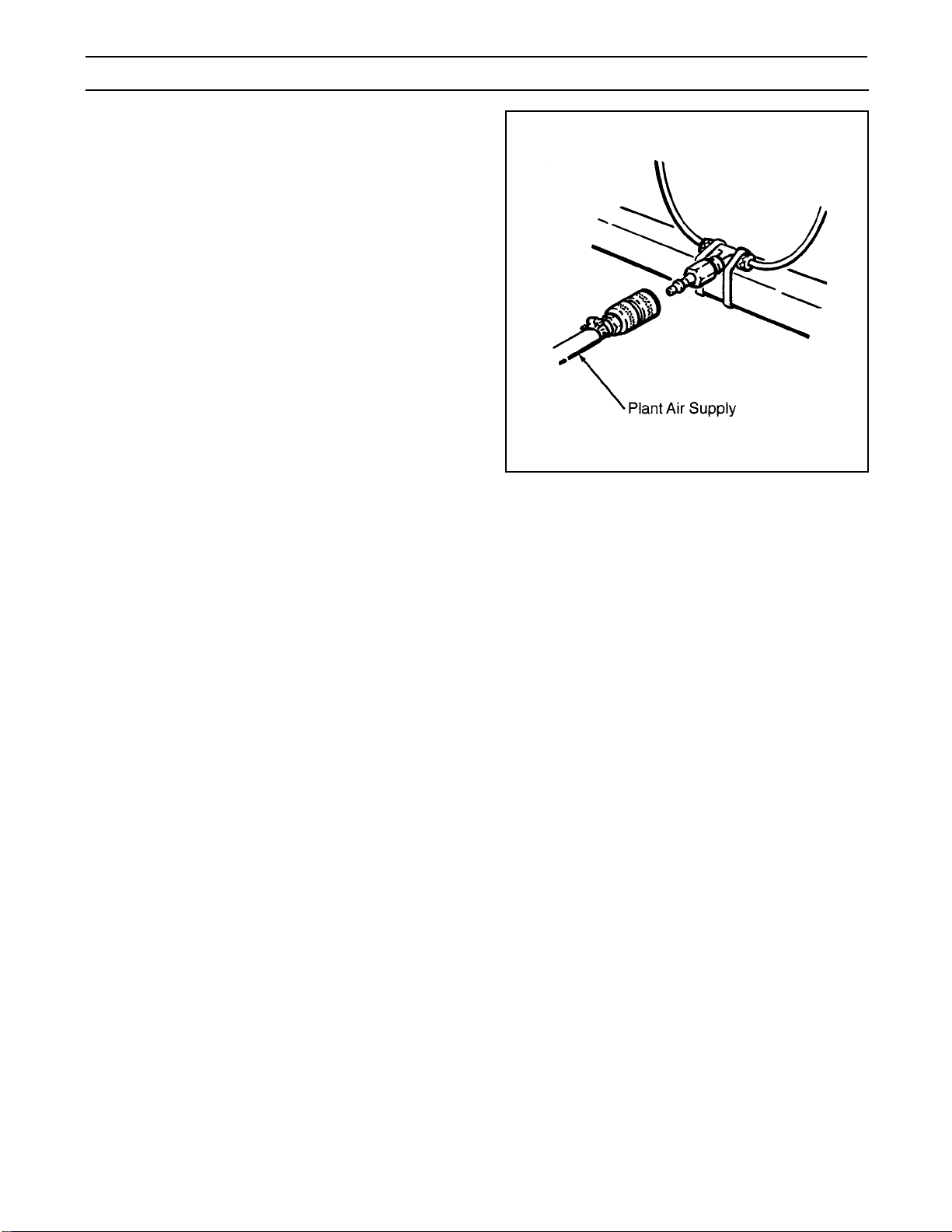

−Turnairsupplyoffanddisconnectbefore

performinganyadjustments,maintenanceor

servicingthemachine

−Turnthemachine off while not in use

−Neverattempt to work on any partof the

machine or load tape while the machine is

running

WARNING

Important–Intheeventthefollowingsafety

labels are damaged or destroyed, they must

be replaced to ensure operator safety.

Replacementpartnumbersforindividual

labelsareshownin "ImportantSafeguards,"

at thebeginningofSectionII.